Advantages and Disadvantages of Centrifugal PumpsA centrifugal pump's operation relies upon forced vortex flow. The term "forced vortex flow" describes the phenomenon wherein the static pressure of a liquid increase when a given quantity of fluid spins under the influence of an external force (producing an external torque). Due to this increased static pressure, water travels from one location to another. A centrifugal force is provided towards the casing, which causes the fluid to flow inside of it.

The forced vortex flow theory underlies how the centrifugal pump works. A increase in the spinning liquid's pressure head happens when a specified fluid volume or liquid is allowed to spin by an external torque. By using this rise in pressure head, water may be transported between locations. Centrifugal force is applied to the casing, which causes the fluid to flow inside of it. A centrifugal pump is a vital piece of equipment for industrial uses. Definition of a Centrifugal PumpThe most typical kind of pump used to move fluids is a centrifugal pump. To put it simply, it applies centrifugal force to certain other fluids using a revolving impeller. This is the preferred option, particularly when transferring the fluid between two locations in a wide range of industrial applications, such as municipality (water and sewage facilities), agricultural, power generating, mining, and chemical and petroleum sectors, among others. Centrifugal pumps can handle massive volumes of fluid and extremely high flow rates. Additionally, they have a broad range of flow rate adjustments.

Centrifugal pumps are often designed to perform well enough with fluids with fairly low viscosity, like water or light oil. Centrifugal pumps need more power to function when dealing with more viscous fluids. Pumps with positive displacement outperform centrifugal pumps in the handling of fluids with greater viscosities, which helps save on energy. For numerous fluid transfer operations, centrifugal pumps are taken into consideration. As a result, these pumps are increasingly preferred in several sectors. Centrifugal pumps are most often used for water delivery, water pumping, supporting fire protection systems, and controlling hot water. Uses for Centrifugal PumpNumerous uses for centrifugal pumps may be found, such as the following:

Primary Parts of Centrifugal PumpMain components of a centrifugal pump are: 1. Impeller

It is a wheel or rotor that has many backward-curving vanes or blades. It is the main shaft that is connected to an external power source, and this shaft is where the impeller receives the liquid energy that causes it to revolve. Fig: Open, Semi Enclosed and Enclosed Impeller. Three kinds of impellers are distinguished:

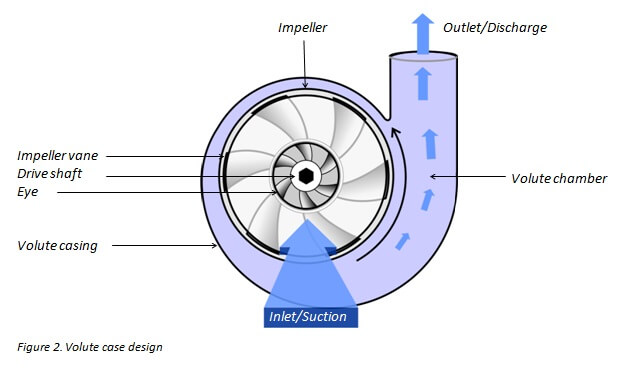

2. Casing

It consists of a pipe that is joined at the top to the pump's intake and the impeller's eye, also called the eye of the impeller. The double-end response pump comprises two suction pipes that are joined to the eye on both sides. To raise, the bottom end dunks into the liquid. The foot valves and strainer are attached to the bottom end. Centrifugal pumps' main components. Three different kinds of casing are often used in centrifugal pumps:

3. Supply PipeIt's a pipe that is linked to the pump's outlet now at the low end of the scale and transports the fluid to the necessary height. A valve is supplied close to the pump's exit on the delivery pipe to adjust the flow from the pumping into the delivery line. 4. Vacuum Pipe with Foot Valves and StrainerThe vacuum pipe's opposite end is sunk into the water sump and is linked to the impeller's inlet. A foot valve and a filter are located at the water's edge. The foot valve has a one-way operation and opens upward. To avoid clogging up the centrifugal pump, the strainer is employed to filter out any undesirable particles that are present in the water. Different Centrifugal Pump TypesCentrifugal pumps may be categorized using various techniques, such as purpose, construction codes, impeller kinds, numbers, etc. The most typical classification schemes for centrifugal pumps are described in this section. I. Centrifugal pumps are categorised according to the kind of flow they produce.

In radial pumps, the liquid exits the impeller after it has rotated 90 ° concerning the suction. This group includes the most prevalent centrifugal pumps. A vertical outflow flange is where fluid leaves after entering the horizontal suction flange. As a result, the discharge is parallel to the pump's shaft. When flow is restricted, and you need to increase discharge pressure, this design is used. As a result, radial design pumps have high pressure and modest flow rates. Most pumps used in oil and gas industries come under this heading.

The fluid is moved through the shaft in such a single direction by axial flow pumps. A propellant works in a manner similar to this procedure. High discharge rates and low-pressure heads are the two conditions where this pump is most useful. These are typical, for instance, in circulation of water and drainage pumps.

A mixed flow pump, as its name suggests, mixes radial and axial fluid characteristics as it circulates. In that respect, radial and axial pumps differ from one another. High flow rates and a high head rise are characteristics of mixed pumps. II. Centrifugal pumps are categorised based on how many stages they have.

The higher-pressure head increase for this centrifugal pumps is 125 m. The one impeller is intended to be effective at high flow rates and relatively low-pressure heads.

Fig: Single-stage centrifugal pump

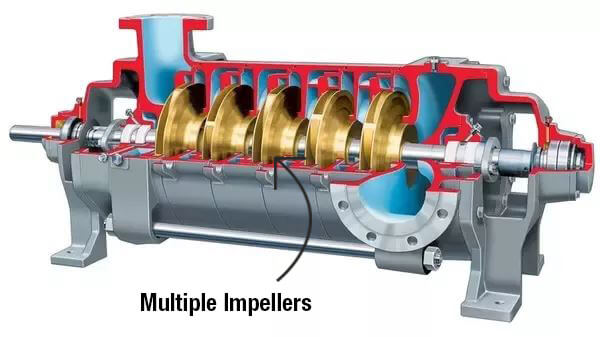

The pump's exit may experience very high fluid pressure. Consequently, the multistage pump is applied when a particularly high head at release is required. For each step of this system, the fluid pressure is increased by connecting impellers in series.

Fig: Multistage Pump III. Volute Types Used to Classify Centrifugal Pumps

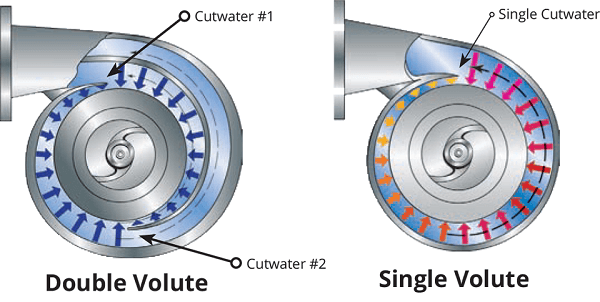

The fluid flows a singular volute which loops completely all-around impeller after leaving the casing with just a single volute. Flow is directed to the pump's outlet by a single cut-water throughout this casing. In the refinery, single volute pumps make up the majority of the equipment.

Two cut waters that are 180 degrees apart are found in a twin volute case. Over a single, a double volute provides an advantage. Whenever the pump runs beyond the BEP (maximum efficiency point), it lessens the shaft fault (BEP).

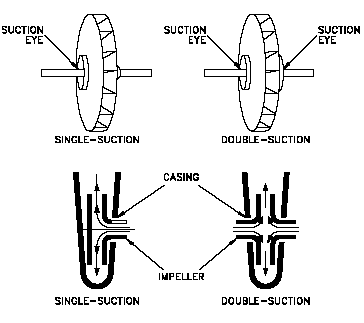

IV. Using the Number of Suctions to Classify Centrifugal Pumps

If a single-suction centrifugal pump is being used, the water can enter its inlet and immediately flows entirely into the impeller's eye. The force brought on by the centrifugal develops as the water leaves the impeller.

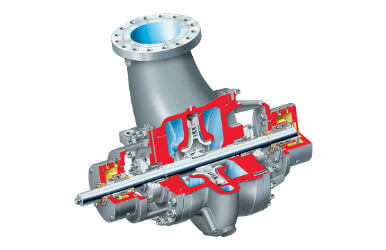

Whenever the flow velocity is too great, a single suction cannot handle the situation. Centrifugal pumps with two suction ports are used in this situation. In contrast to a usual circumstance, the impeller of this pump is designed to enable liquid to emerge from both sides. The phrase "double suction" should not, however, be taken in error. There is just one suction and discharge flange, even with the twin suction configuration. The impeller and casing are different in how they are made.

V. Centrifugal pumps are categorised based on how their shafts are oriented.

A vertical pump has a shaft that is vertically oriented, and it is often installed in the sump. These pumps are used in small spaces. This category consists of pumps and sump collection equipment used during borewells.

Fig: Vertical centrifugal pump

Considering how simple they are to maintain, the horizontal pump is more often employed. This design positions the shaft horizontally.

Fig: Horizontal centrifugal pump VI. Impeller position is used to classify centrifugal pumps.

The impeller is situated towards the tip of a shaft which bulges the bearing within a segment impeller pump. This pump has a single bearing that supports the impeller. The pump may be installed both vertically and horizontally with this arrangement.

Fig: Overhung impeller pump

The impeller is linked to a centrifugal pump's shaft, which is suspended in opposing directions at both ends. These pumps use horizontal multistage construction.

Fig: Between Bearing Pump How Centrifugal Pumps WorkA centrifugal pump must be set before it may begin to operate. When a pump is prepared, the fluid that will be circulated is positioned inside the vacuum pipe case of the pump, as well as all air is forced out of the pump's location, and also no air is left. A centrifugal pump has to be primed because the density of the fluid in contact with its impeller directly affects the pressure that is produced there.

The delivery valve is maintained closed after the pump has been primed while the impeller is being rotated by an electric motor that has just been turned on. When the delivery valve opens, the liquid is compelled to flow outward in a radial direction, and a vacuum is produced due to the centrifugal action of the impeller's elevated impeller vanes there at the outer circle. This results in a lengthy discharge from the center of the impeller that is used to elevate liquid to the necessary height via the discharge port, substituting the flow of fluid from the pit through the piping system to the impeller's eye. Advantages of Centrifugal Pumps

Disadvantages of Centrifugal Pump

ConclusionThe centrifugal pump is being used more frequently than any other application in today's technologically advanced world of competition due to its benefits in terms of cost, reliability, discharging, which is constant and equal, and ease of installation and maintenance. All pumping applications may benefit from centrifugal pumps because of their exceptionally simple nature. |

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share