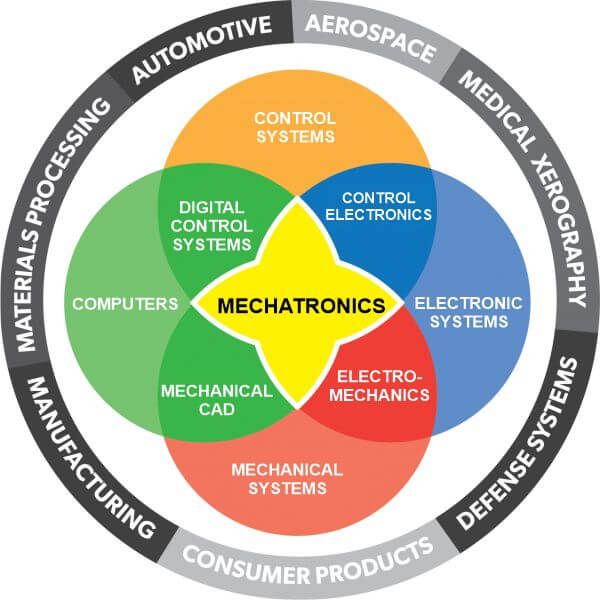

Advantages And Disadvantages Of MechatronicsMechatronics is a multidisciplinary field of engineering that combines elements from mechanical engineering, electrical engineering, telecommunications engineering, control engineering, and computer engineering. It is a combined electrical and mechanical systems engineering field that may include aspects of automation, actuation, and control. The word mechatronics was first coined in 1969 by Tetsuro Mori, an engineer working for the Japanese company Yaskawa Electric Corporation. Since then, mechatronics has become increasingly popular in the engineering and manufacturing industries. Mechatronics involves designing and manufacturing devices that integrate the disciplines of electrical, mechanical, and computer engineering. This can include robots, automated mechanisms, and industrial machines accessed via and programmed through software. The aim is to create sophisticated systems to optimize performance, reduce costs and improve reliability. Mechatronics is used in many industries, from automotive engineering to medical robotics, home automation, and the entertainment and communications industries. This engineering form is increasingly used in industrial automation, where machines are programmed to perform specific tasks autonomously. In the medical industry, mechatronics is used to build artificial limbs, assistive technologies, rehabilitation robotics, and surgical robotics. In-home automation, this type of engineering can be used to control climate, lighting, and other elements. In the entertainment industry, mechatronic systems are used in motion-sensing gaming consoles, animatronics, and 3D cinema systems. In long-distance communications, mechatronic systems are used in satellite communications systems and mobile phone networks. In essence, mechatronics is a type of engineering that looks to combine different engineering disciplines to create complex, automated, and robotic systems. This type of engineering can help improve device performance and reliability, reduce costs, and create more efficient and automated processes.

Types Of MechatronicsServo-Mechatronics Servo-Mechatronics combines servo-mechanisms with a device's mechanical, electrical, and environmental components to simplify its control system. This type of mechatronics is often used in complex control systems like robotics, motorized actuators, and vessels. Servo-mechanisms, also known as servos, convert a small electrical signal into movement. This mechatronic system is ideal for tasks requiring precise movements, such as those in the aerospace industry. Intelligent-Mechatronics Intelligent mechatronic systems combine advanced computer systems with electronic and mechanical components to enable automatic operation. This type of mechatronics is commonly used to automate industrial processes, such as welding, machining, and assembly. These systems can monitor, measure, and adjust their performance based on feedback to optimize the production process and ensure continued quality over time. Adaptive-Mechatronics Adaptive mechatronics combines sensors, machines, and motors with adaptive algorithms to create an intelligent control system. The sensors collect data which the system then uses to adjust its performance to meet the changing needs of the application. This type of mechatronics is used in various industries, including automotive, aerospace, and medical. Closed-Loop-Mechatronics Closed-loop mechatronics combines electrical, mechanical, and computer-controlled systems with feedback to monitor the operation of a device or system. This type of mechatronics is used for applications where high accuracy and precision are required, such as the manufacturing of medical devices. The feedback from the system allows it to adjust its performance based on the data it collects to ensure accurate operation. Advantages Of MechatronicsMechatronics offers a range of advantages over conventional techniques. Its main advantages are increased efficiency and accuracy, cost savings, improved safety, and improved reliability.

Improved Efficiency and AccuracyMechatronics is a multidisciplinary engineering field that combines electrical, mechanical, and computer engineering techniques to create automated systems. This innovative engineering technology is highly valued in industries ranging from automotive and aerospace to defense and medical. As an integral part of Industry 4.0, mechatronics provides users various advantages in improved efficiency, accuracy, and cost-effectiveness. One of the primary benefits of mechatronics is improved efficiency. Automated systems created with mechatronics can process and analyze data significantly faster than human efforts. This can drastically reduce the time needed for tasks, allowing for faster completion of projects and increased productivity levels. Additionally, mechatronics systems are extremely reliable and accurate. Their sensors and precision control features enable an automated system to complete a task to exact specifications without the possibility of errors commonly associated with human labor. As a result, companies can rest assured that their end products are of the highest quality. Mechatronics can also provide cost savings to businesses. Automated systems can save money that is traditionally spent on labor costs. In addition, these systems require little maintenance and do not require nearly as much energy as manual labor to operate. High Initial Cost That Ensures Top- Notch SystemsMechatronics is an emerging discipline that combines electrical, computer, and mechanical engineering principles to create efficient engineering systems. It is also used to solve problems associated with mechanical and electrical systems, as well as facilitate communication between them. As a result, Mechatronics is a powerful tool for a modern engineer who needs to optimize system performance. The main advantages of mechatronics are its high initial cost and its Flexibility. The high initial cost is a benefit because it helps ensure a system is prepared for future developments, such as new technology and possible application changes. This helps systems remain pertinent in various markets, as it can adapt to different conditions. Another advantage of mechatronics is its Flexibility. The combination of electrical and mechanical components allows mechatronic systems to be modified and adapted, offering greater function and a longer lifespan than traditional systems. This means that, in the long run, mechatronic systems usually offer a higher return on investment when compared to traditional systems. New technologies are also being developed, such as Big Data and Artificial Intelligence, making mechatronic systems even more powerful and adaptive. Furthermore, mechatronic systems improve safety by eliminating potential failures from mechanical, electronic, and communication components. With a well-implemented mechatronic system, potential failures are identified and rectified before they cause damage or other issues. This improved reliability and safety that mechatronic systems offer makes them highly advantageous for industrial, automotive, and even medical applications. Therefore, the high initial cost and Flexibility of mechatronics make it a powerful tool for modern engineers who need to scale their operations and reduce risk. The safety, reliability, and performance improvements make mechatronic systems an attractive, cost-effective option over traditional systems. Complexity That Boosts EfficiencyMechatronics is quickly gaining traction as a disruptive technology in the world of automation and robotics. This advanced engineering discipline merges elements from electronic and mechanical engineering to design and engineer complex, automated systems successfully. As technology expands, mechatronics finds its place in various industrial, biomedical, and research fields. But what advantages does mechatronics bring to the table? Its greatest power is arguably its complexity. By creating systems that integrate multiple technological components and capabilities, mechatronics engineering can boost efficiency across various applications. In industrial settings, mechatronics can increase production throughput and reduce high human labor levels. It is particularly useful when combined with Artificial Intelligence (AI) to optimize production. Mechatronics ensures a more efficient and autonomous system through its multiple components, resulting in more accurate and fully automated production. In biomedical recommendations and treatments, mechatronics plays an essential role in developing end-user products tailored to individual needs. Through its advanced analytics capabilities, mechatronics can analyze a wide range of health data in real-time and go beyond medical history to develop personalized recommendations and treatments. In research, mechatronics creates robots that can operate in extreme conditions, such as deep ocean dives or dangerous outer space explorations. This allows for complex scientific studies under different physical conditions and provides valuable data for further analysis. The complexity of mechatronics is an undeniable advantage in multiple industries due to its scientific accuracy, economic efficiency, and ability to tackle complex problems. As the world moves towards a more digitized future, mechatronics will continue to lead the way as an innovative and effective tool for designing and engineering increasingly complex systems. Minimal Maintenance CostsMechatronics is a combination of mechanical engineering, electrical engineering, and computer engineering. It combines systems engineering, robotics, control engineering, and other fields. By integrating these fields, mechatronics can create computer-controlled systems that interact with their environment. The advantages of mechatronics include improved control over mechanical systems, better efficiency, more accurate sensing, and higher reliability. Maintenance of mechatronic systems is typically very low since the components are automated and electrical rather than mechanical. This can save production costs, improve maintenance predictability, and reduce equipment downtime. In many cases, mechatronic systems require little to no maintenance. For example, a robotic arm in a factory does not require regular oiling or replacement of parts. In cases where maintenance is necessary, it can be carried out via remote access, requiring fewer maintenance personnel to be close to the hazardous system components. Capable Of Performing Complex TasksMechatronics is the integration of mechanical, electrical, and computing technology into a single system, or system of systems, that is capable of performing complex tasks and functioning as an interconnected system. The use of mechatronics is becoming increasingly widespread for various applications, ranging from robotics and other manufacturing processes to consumer and commercial products. One of the major benefits of mechatronics is its Flexibility. Mechatronic systems are designed to operate in a wide range of environments and operate under many different conditions. A mechatronic system can easily adapt or change to meet new requirements or demands. This Flexibility allows the system to be reconfigured to meet the needs of different customers, applications, and environmental conditions. Another advantage of mechatronics is its limited Flexibility. Because the system is designed around a single, common architecture, its Flexibility is limited. This limited Flexibility prevents the system from making major changes or performing new tasks. This can be beneficial in certain scenarios, such as when the goals and objectives of the system are very well understood, and the system doesn't need to be modified to meet the demands of changing conditions. In addition, mechatronic systems are generally maintenance-free. The overall complexity of the system, as well as its limited Flexibility, means that it can be operated for long periods without the need for maintenance. This helps reduce operational costs and ensures that the system remains reliable and efficient over time. Reduced Risk of FailureMechatronics is a combination of mechanical, electrical, and software engineering that applies engineering principles to the design, manufacture, and operation of automated systems. This technology facilitates the development of complex systems, which can produce cost and time savings for companies, compared to designing and manufacturing each system separately. Mechatronics also facilitates more efficient use of resources due to its ability to reduce the risk of Failure and improve the overall system performance. Using the principles and technologies of mechatronics can reduce the risk of Failure in many ways. First, all system components are integrated into each other in a controlled and unified way, thus creating a tight relationship between the parts, each of which is designed with specific features and abilities. This ensures that the system operates as an organized and unified whole, reducing the risk of individual components failing due to incompatibilities or technical issues that may otherwise arise. Secondly, mechatronics allows us to use advanced sensors and controllers in an automated system to monitor, react and adjust its operations when needed, which helps to detect and prevent any potential problems from occurring. Using this technology, we can also record and store data, which can detect when something is off and quickly address any potential problems. As a result, this reduces the potential for system failure and maximizes the overall performance and efficiency of the automated system. Disadvantages Of MechatronicsMechatronics is a rapidly growing field with some positive implications for various industries. However, there are also some potentially negative consequences associated with this technology. Here are some of the main potential drawbacks of mechatronics. Mechatronics combines the disciplines of mechanical engineering, electronics, and computer engineering. It is used extensively in application areas, including product design and development, servo-mechanisms, manufacturing automation, robotics, and security systems. One of the largest disadvantages of mechatronics is its complexity. The complexity of mechatronics results from integrating multiple systems and components, each with its unique set of specifications and performance requirements. The integration process requires a great deal of technical knowledge and skill and a deep understanding of how each component interacts with the whole system. Additionally, mechatronics systems can contain components such as computer hardware, mechanical system parts, and software applications, all of which must be properly maintained and operated. The complexity of mechatronics systems can lead to issues with management and communication.

There is an increased likelihood of confusion and miscommunication between the different departments dealing with the system, as all personnel may have different levels of technical understanding. Furthermore, overall project management of a complex mechatronics system can be very challenging, as details can be easily overlooked or forgotten. Expensive to set upOne of the disadvantages of mechatronics is the cost of setting up the system. Mechatronics systems require multiple components and sophisticated hardware to detect and analyze data from multiple sources. This requires significant engineering expertise, as well as substantial computing power. This expertise and hardware add up quickly and can be expensive upfront. In addition, repairs and replacement parts for malfunctioning components are often expensive. Smaller businesses and organizations may be unable to invest in mechatronics because of these high costs, particularly when compared to simpler systems that require fewer resources to build and maintain. Businesses that decide mechatronics is a good fit typically need to plan for higher overhead costs than they would with simpler systems. They may need to budget for upgrades and new components as the system ages and technology advances, which can add up to a hefty sum over time. Requires Regular ManagementMechatronics is an advanced form of automation that combines mechanics and electronics to create more efficient and reliable automated systems. However, these systems require a significant investment in time and money to maintain and operate. The biggest disadvantage of mechatronics systems is their need for constant maintenance. Because they have multiple components that need to be synchronized to keep the system functioning correctly, any short-term failure can be costly and time-consuming. Regular maintenance procedures are necessary to ensure that each component functions correctly and the entire system runs efficiently. In addition, mechatronics systems are prone to software errors, which can be difficult and slow to diagnose and fix. If the software code is not properly designed or updated, it will not work as intended and could lead to system malfunctions. If the software is regularly updated, it may succeed in keeping up with the system's demands, resulting in serious delay or disruption. Finally, mechatronics systems are generally more complicated to operate and require greater expertise. This means that operators must be properly trained to use the system efficiently, which is an additional cost to consider. Complicated To OperateMechatronics is a rapidly evolving field of engineering that combines electrical, mechanical, and software engineering. It creates automated systems and devices, such as robotic surgical and automated vehicles. While mechatronics offers great potential for automated and advanced systems, it cannot be easy to operate. One of the disadvantages of mechatronics is that it can be extremely complicated to operate. It requires an in-depth knowledge of a broad range of topics and a deep understanding of the various components and functions. This makes it difficult for the average person to gain the necessary skills to operate the equipment properly. Furthermore, mechatronics systems can be costly to develop and maintain. High-end mechatronic systems require expensive components and programming costs. Finally, mechatronic systems can be prone to error and may fail without warning. Since the systems are so complex and require a deep understanding of the numerous components and processes, it can take time to troubleshoot any problems. This can be a major disruption for those depending on the system. Potential For Security BreachesMechatronics combines mechanical engineering and electronics technology and is a rapidly growing technology field. However, the potential for security breaches and unauthorized access to data and systems associated with mechatronics is a significant disadvantage. The potential for security breaches associated with mechatronics is largely due to the use of networked systems and digital data for various processes and tasks. Malicious actors may use security vulnerabilities to access data and systems in such systems. This could lead to a wide range of negative outcomes, from the disruption of normal operations and the theft of sensitive data or intellectual property to even more serious issues, such as physical harm. In addition, because mechatronics systems often involve a variety of interconnected devices and components, attackers may be able to exploit system weaknesses to access and navigate this network. This could allow malicious actors to access all interconnected systems and manipulate data and processes at will. Furthermore, mechatronic systems typically involve cloud-based storage, meaning that data and systems can be more easily exposed to malicious attacks. Even if data is properly secured, hackers can still attack the storage servers and potentially access sensitive information. Finally, using intelligent robots and autonomous systems opens up the possibility of cyberattacks on these systems, with potentially disastrous consequences. For organizations and companies that utilize mechatronic systems, it is important to take appropriate measures to ensure the maximum possible security of these systems. This includes properly securing data and systems, implementing secure network architecture and utilizing secure Internet protocols, maintaining and regularly updating system software, and taking other measures to reduce the risk of security breaches. Lack Of TransparencyA lack of transparency in mechatronics can lead to various disadvantages, from stalled projects to product failure and customer dissatisfaction. The problem often stems from a disconnect between what designers and engineers plan for the system and how it performs under field conditions. With a full understanding of a system's architecture, it can be easier to predict how the system will behave under particular conditions or diagnose the cause of a particular problem. For example, when customers purchase a mechatronic system, they usually need a greater understanding of its components and how they interact. In many cases, they may need to learn what components they're dealing with. This can lead to delays in troubleshooting and debugging since it's hard to address a problem before you understand what's wrong. This can result in wasted time, money, and resources and decreased customer satisfaction. A lack of transparency also makes it difficult to predict system complexity and dependencies which, in turn, can lead to underestimated costs, missed deadlines, and increased costs due to rework. Further, stakeholders may have unrealistic expectations about the system's performance, leading to customer frustration. The best way to avert these issues is to adopt a modular approach for the mechatronic system. This requires a clear understanding of its architecture, which necessitates clarity and transparency in the design and deployment stage. With transparency and visibility into the system's architecture, a mechatronic system can be efficiently designed, constructed, or maintained. ConclusionThe advantages and disadvantages of mechatronics depend on its application and implementation. Mechatronics is a powerful technology that can provide higher performance and efficiency when implemented correctly and reduce the complexity of the systems and processes it replaces. On the other hand, when implemented incorrectly, mechatronics can complicate the system and increase costs. Overall, mechatronics has the potential to bring about many benefits, including increased efficiency and improved performance, but it must be considered carefully before being implemented into any system.

Next TopicAdvantages and Disadvantages of Fax

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share