Advantages and Disadvantages of Pre-stressed Concrete

To enhance the properties of pre-stressed Concrete, internal stresses are purposefully introduced into the system without using any external loads. Internal tensions are created in the concrete structure to balance the pressures from the exterior load application.

The idea of pre-stressing

For the concrete structure to be able to resist or sustain the stresses brought on by the service loads, pre-stressing, as previously noted, necessitates applying an initial load to the structure. The illustration of a barrel makes the idea simple to grasp. Metal bands bind a barrel once tightly used to convey liquids and grains. Due to the tight fit of these metal rings, the barrel is encircled by a hoop. This barrel develops hoop tension when it is filled with liquid. The metal bands' hoop compression somewhat counters the pressure produced by the fluid inside. This system is known as pre-stressing. Similarly, compelling internal tensions are introduced into the Concrete using pre-stressing iron bars just before the concrete structure is exposed to any service loads. Stresses from outside the body balance this tension.

Need for Concrete Pre-stressing

The following problem can be used to justify the requirement for pre-stressing in Concrete:

- Concrete is strong in compression but weak in tension. Early flexural fracture develops due to this concrete weakness, mostly in flexural elements like slabs and beams. To avoid this, Concrete is intentionally placed under compressive stress (pre-stressing), balancing off the shear strain the structure experiences while in use. Flexural cracks are, therefore, less likely as a result.

- The flexural members' bending, shear, and torsional capacities are improved by the pre-compression, which is brought about as a result of pre-stressing.

- Depending on the member's longitudinal orientation, a compressed pre-tensioned force can be applied concentrically or eccentrically, which protects against cracks at the vital midspan and offers support at the service load.

- A portion of pre-stressed Concrete always displays elastic properties.

- When using pre-stressed Concrete, the entire depth may be fully loaded, while the Concrete can be used to its total capacity in compression.

Techniques used for Pre-stressing

There are two ways to do the pre-stressing:

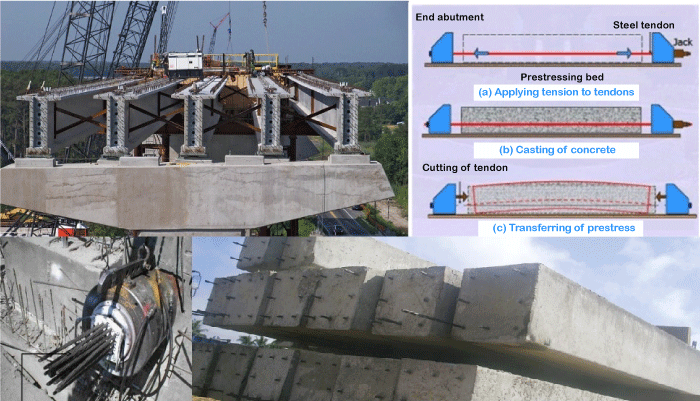

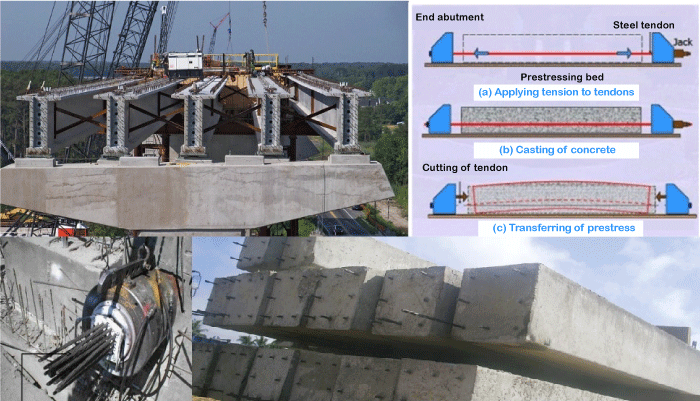

1. Pre-tensioning

The steel tendons are originally tensioned in the pre-tensioning process to create stress. In between the end anchors, tensioned wires or strands are present. Following this tensioning procedure, the Concrete is formed. The end anchorages are freed once the cast concrete has sufficiently been set. The pre-stress force is transmitted to the Concrete by this release. The link between the steel tendons and the Concrete greatly aids this stress transfer.

2. Post Tensioning

In this case, the steel is only pre-stressed after the beam has already been cast, cured,

and grown sufficiently strong to withstand the pre-stress. Concrete is released within the sheathing, and concrete ducts are designed to allow the circulation of steel cables.

The following are the advantages of pre-stressing Concrete in Construction

- Strengthens the structure: By generating an internal compression force to balance the traction force created by the stresses of the structural parts, the pre-stressed process offers additional concrete strength.

- The extensiveness of the constructions: The absence of cracks at all load levels is one of the significant advantages of pre-stressed beams. This lack of cracking indicates that the structure can endure loads, impacts, vibration, and knocks while reducing the likelihood of rusting in the steel, prolonging the construction's durability.

- Increased saving: Due to the size of the parts, the use of tensile Concrete enables the construction of wide spans while reducing material use and increasing mass. An instance of this is tensile pre-stressed beams to provide higher lighting while enclosing large open spaces, such as industrial warehouses. For example, using concrete plates in car park covers allows for more spacing between the loading columns, improved space use, and significant material savings.

- Design: Pre-stressed concrete parts offer countless building possibilities and more practical and attractive aesthetic aspects.

- Construction speed: Accelerated building by simultaneously building different areas of the structure or attacking many lines. In a comprehensive review of the work's economic and financial aspects, this essential value has enormous economic benefits.

- Sustainable yet environmentally safe: You cannot ignore the ability of precast Concrete to get rid of clusters and other materials at the building sites when evaluating its benefits. Perhaps one of precast Concrete's many benefits is its sustainability. Precast Concrete also requires a single setup and transport on the site. Hence, fewer workers are needed than with cast-in-place Concrete. Since there won't be any raw materials stock-piled on the construction site to create precast Concrete, a safe workplace is offered. Due to the reduced congestion, there will also be a lower risk of workplace accidents.

- Reduced noise: Precast Concrete has the advantage of having excellent sound absorption, which tremendously minimizes noise. Due to its qualities as a sound barrier, it is a frequently used material for commercial properties. Precast walls are perfect in complexes, hotels, and flats since they are thick and adequately filter out extra noise.

- Easily Maintained: Products made of precast Concrete are particularly sustainable because they are sturdy and long-lasting. Pre-stressed Concrete can be produced using entirely recyclable materials and wastewater. Products made of precast Concrete don't need to be changed out very often because the material requires little management. Precast goods are, therefore, ideal for any project construction because of the fantastic properties that enable them to last quite a long time.

The following are the disadvantages of Pre-stressed Concrete

- Tower cranes and other technical equipment are required if Precast Concrete is to be constructed for a high-rise building.

- Precast Concrete is generally dense after settling. Therefore, you should take extra care when transporting it because many impacts could harm it.

- Unlike cast-in-place Concrete, precast Concrete must be carried from the factory to the project site. Since you must move it, your transportation expenses will increase, and the time for delivery may be affected by this.

Conclusion

Precast Concrete has several benefits than drawbacks, making it incredibly popular in the manufacturing and construction sectors.

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now