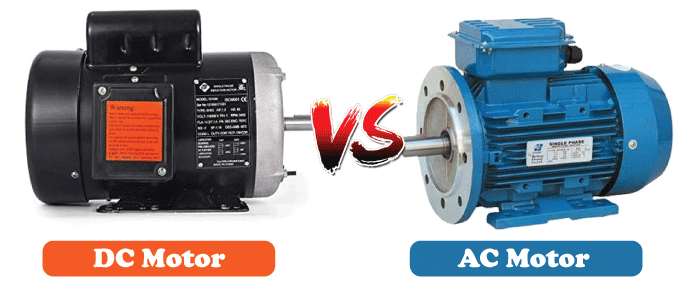

Difference Between AC and DC MotorFrom Industrial to household appliance, everyday modern- day application requires Electric Motors. The vital role that electrical motors play is to covert the electrical energy into mechanical energy to make the device work with full range. There are generally two types of motors thar are applied in modern appliances- AC (Alternative Current) and DC (Direct Current) motors to make the appliance work in power. Both the motors have a single purpose I.e., to make the appliance work in the best way possible, the only difference between them is the way they function and they both serve different advantages and disadvantages as well.

In this article, we will explore magnificent differences that are found between AC and DC motors. Our differences will concentrate on construction, operation, performance, and on applications. Construction and ComponentThe major difference that you will find in AC and DC motor is in their design and parts. If we compare DC motor with AC motor, we will find that AC motor has more parts and is more complex as compared to DC motor. Rotor, Stator, and Armature are few essential components present in the AC motor. The Rotor, which is the rotating part of the motor is made out of stack of steel plates that have been laminated. The Stator is a stationary part whose role is to house the winding that generates the magnetic field. The magnetic energy is turned into mechanical energy by connecting the rotor with the armature. Now let's have a look at the structure of DC Motor. DC motor has a simple and straightforward design. The Rotor, Stator, and Commutator are the main parts of DC Motor. The Rotor is made by a stack of laminated steel plates that is quiet similar to the rotor of AC motor. In DC motor, the magnetic field is also created by winding inside the stator. In DC Motor, the armature is replaced by the Commutator, which helps the current to flow in a single direction and it also gives DC motor its distinctive torque. It is important to know the difference between the design of both the motors as it impacts the functionality and efficiency as well. Due to the conversion of AC power to mechanical energy that eventually leads to energy loss, AC motors are said to be less efficient as compared to the DC motors. If you want to increase the efficiency of AC Motor, then you have to adjust the frequency and voltage of the power supplied to the motor, through this you will be able to change the VFD- Variable Frequency Drives that can indeed increase the efficiency of the motor. On the other hand, DC Motor is known for its amazing efficiency which is almost of 90%. This is said because DC motor function with the direct current which is anyhow better than the alternate current that is been utilized by AC motor to function in a proper manner. Another point that makes DC motor stand on a higher position than the AC motor is that the maintenance and the repair is quite simple of DC motor, which eventually makes it a popular option for many applications.

Operation and PerformanceAnother major difference that you should check before going for AC or DC motor is their operation and performance. As stated earlier, AC Motor operates with the use of alternative current, the direction of the current occasionally changes. Whereas, DC Motor operates well with direct current which means that the current typically flows in one single direction. The basic difference that we can locate is how things work in a number of significant performance traits. Lets have a look at the advantages served by AC Motor:

Lets have a look at the Advantages of DC Motors:

ApplicationsThe third and one of the most vital difference between AC and DC Motor is their compatibility with specific applications. Applications that require high speed and a constant torque at variable speeds go best with AC Motors, such as fans, pumps, and compressors. AC Motors also go well with machinery that require specific and precise control like CNC machines and robotics. On the other hand, DC Motors are best for the applications that require high starting torque at low speeds. Applications like electric vehicles, cranes and conveyor belts perform their functions with DC Motors. DC Motors are generally used in battery-operated applications, like portable power tools and electric bikes, due to their requirement of high efficiency and easy control which can be fulfilled with DC Motor only. Here is a difference table that will summaries the differences between AC and DC Motors: Difference Table

By choosing the most appropriate motor for your specific device or application, engineer and designer can indeed increase the appliances' performance, efficiency, and cost effectiveness as well. Through this, they will indeed be able to make their appliance and indispensable component in modern-day applications and devices as well. ConclusionBoth the motors have their unique features, advantages and disadvantages as well. It is important to know the differences between AC and DC Motors so that you can choose the right motor for your specific application to perform their function at the best possible power. AC Motors are specifically designed for applications that require high-speed and precise control. On the other hand, DC Motor is designed for applications that require high starting torque at low speed and for applications that are battery-operated. By knowing the specific differences between AC and DC Motors, it will become easy for you to choose the right one for your demonstration of any appliance.

Next TopicDifference between

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share