Difference Between Stress and StrainIntroductionStress and strain are two important concepts in mechanics and materials science. Both describe how a material or structure responds to external forces or loads. However, despite their similar usage, stress and strain have distinct definitions and characteristics that set them apart.

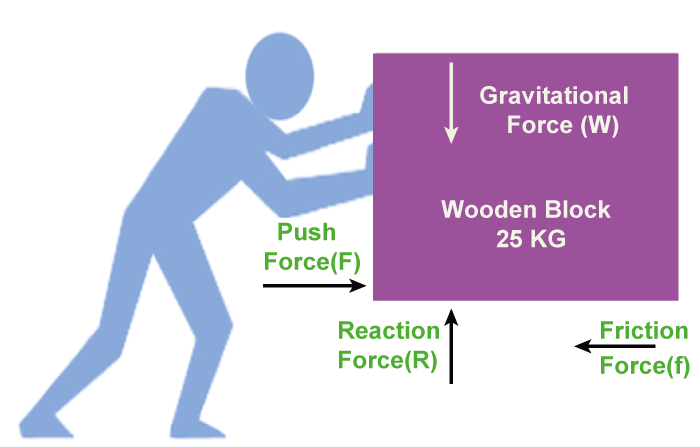

Stress refers to the internal forces that develop within a material or structure in response to an external force or load. These internal forces can be compressive, tensile, or shear and are distributed throughout the material or structure. Units of force per unit area, such as pounds per square inch (psi) or newtons per square meter (Pa), are employed to measure stress. Conversely, strain alludes to the alteration or modification in shape that occurs in a material or structure due to stress. Strain can be described as either linear or angular, depending on the deformation type. Linear strain is expressed as the change in the length of a material or structure relative to its original length. In contrast, angular strain is defined as the change in the angle between two intersecting lines within the material or design. Strain is typically measured as a percentage or as a decimal value. Understanding the difference between stress and strain is important in many applications, particularly in designing and analyzing structures and materials. For example, engineers may use stress and strain measurements to determine the load capacity of a bridge or the strength of a material in a particular application. Additionally, stress and strain are important in fields such as biomechanics, where they study the behavior of biological tissues and structures under stress. In summary, stress, and strain are fundamental concepts in mechanics and materials science. While they are related in that they describe the response of a material or structure to external forces or loads, they have distinct definitions and characteristics that set them apart from one another. Engineers and scientists can better design and analyze structures and materials for various applications by understanding the difference between stress and strain. Definition of Stress and Strain

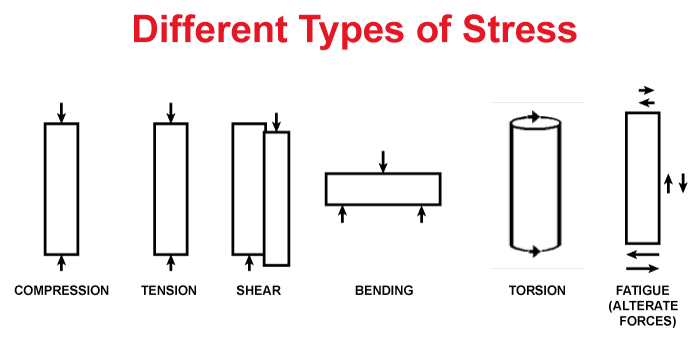

Stress and strain are two important concepts in mechanics and materials science. Stress refers to the internal forces that develop within a material or structure in response to an external pressure or load. It can be defined as the force per unit area distributed throughout the material or design. Stress can be further categorized into three types: compressive stress, tensile stress, and shear stress. Compressive stress refers to the stress that results from the compression of a material or structure, tensile stress refers to the stress that results from the stretching or pulling of a material or structure, and shear stress refers to the stress that results from the sliding or twisting of a material or structure. On the contrary, strain pertains to the alteration or modification in shape that occurs in a material or structure due to stress. Strain can be determined as the ratio of the material's or structure's change in length or angle to its initial length or angle. Strain can be categorized into two types: linear strain and angular strain. Linear strain refers to the change in the length of a material or structure relative to its original length. In contrast, angular strain refers to the change in the angle between two intersecting lines within the material or structure. Both stress and strain are typically measured using standardized units and can be used to describe the mechanical behavior of a wide range of materials and structures. Types of Stress And Strain: Detailed Explanation

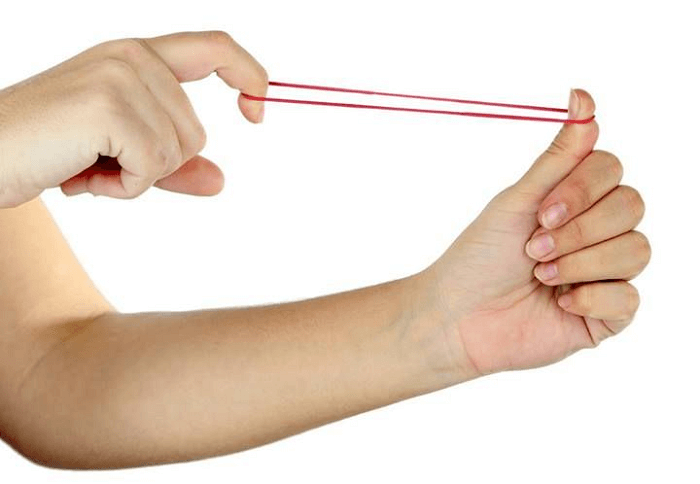

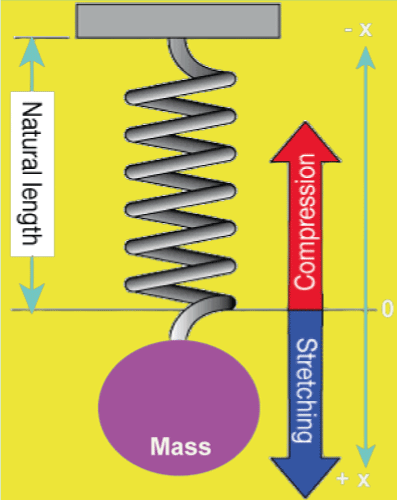

Three types of stress can develop within a material or structure in response to external forces or loads: compressive, tensile, and shear. Compressive stress occurs when a material or structure is subjected to a compressive force that causes it to decrease in length or volume. This type of stress is common in applications such as building foundations, where the structure's weight compresses the underlying soil. Tensile stress, on the other hand, occurs when a material or structure is subjected to a pulling or stretching force that causes it to elongate. This type of stress is common in applications such as bridges or cables, where the structure's weight creates tension in the supporting elements. Shear stress occurs when a material or structure is subjected to a force that causes it to slide or twist. This type of stress is common in applications such as cutting or drilling, where a tool applies a force to the material in a direction perpendicular to the surface. Two strain types can occur in response to stress: linear and angular. Linear strain refers to the change in the length or volume of a material or structure relative to its original length or volume. In contrast, angular strain refers to the change in angle between two intersecting lines within the material or structure. A comprehensive knowledge of both strain types is critical in comprehending the mechanical characteristics of materials and structures under various stress conditions. Relationship between Stress And StrainThe correlation between stress and strain is vital in understanding how materials and structures respond to stress. When materials or structures undergo stress, they experience deformation or a shift in shape. This change in shape or deformation is referred to as a strain. Hooke's law, a fundamental principle in stress-strain analysis, relates stress to strain within the elastic limit of a material, indicating that stress and strain are proportional. This means that if a material or structure is subjected to stress within its elastic limit, it will undergo a proportional strain. The constant of proportionality between stress and strain is known as the modulus of elasticity or Young's modulus. This constant is unique to each material and can be used to predict the amount of deformation or strain that a material will undergo under a given stress. Beyond the elastic limit of a material, the relationship between stress and strain becomes nonlinear, and the material may undergo plastic deformation or even failure. Understanding the relationship between stress and strain is important in many applications, particularly in designing and analyzing structures and materials where the behavior under different types of stress is critical. Difference Table: Stress Vs Strain

Hooke's Law

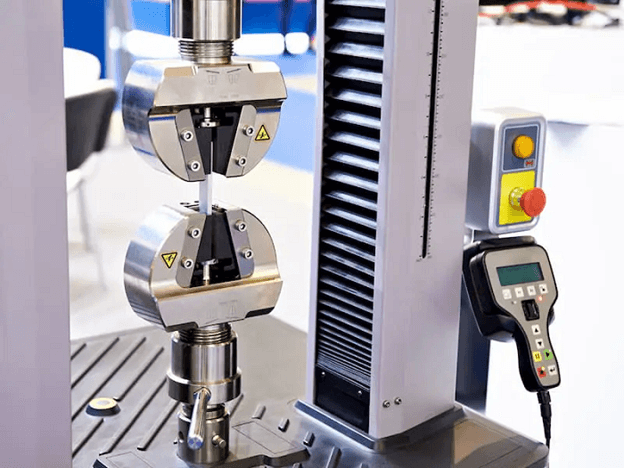

Hooke's law is a fundamental concept in materials science and mechanics, describing the relationship between stress and strain in a material within its elastic limit. According to Hooke's law, the stress within a material or structure is proportional to the strain it experiences. This means that if a material or structure is subjected to stress within its elastic limit, it will undergo a proportional strain. The constant of proportionality between stress and strain is known as the modulus of elasticity or Young's modulus. This constant is unique to each material and can be used to predict the amount of deformation or strain that a material will undergo under a given stress. Hooke's law applies to various materials and structures, including metals, plastics, and ceramics. The stress-strain curve is frequently employed in engineering and design practices to anticipate how materials and structures will behave under varying types of stress. Nonetheless, it should be noted that once a material's elastic limit is exceeded, the relationship between stress and strain becomes nonlinear, leading to possible plastic deformation or complete failure of the material. Therefore, understanding the limitations of Hooke's law is important in designing structures and materials that can withstand different types of stress. Stress-Strain CurveA stress-strain curve visually illustrates the correlation between stress and strain in a given material or structure. It is a vital instrument in comprehending the mechanical properties of materials and structures under diverse types of stress. The stress-strain curve is typically plotted by subjecting a material sample to an increased stress level while measuring the resulting strain. The resulting curve is divided into different regions, each corresponding to a specific mechanical behavior of the material. The first region of the curve is the elastic region, where the material undergoes deformation proportional to the applied stress, according to Hooke's law. In this region, the material will return to its original shape once the stress is removed. The second is the plastic region, where the material undergoes irreversible deformation beyond its elastic limit. The material may deform under increasing stress in this region and eventually fail. The material's ultimate strength is the point at which it fails, typically represented as the peak stress on the stress-strain curve. The slope of the curve in the plastic region is known as the strain hardening slope, and it means the ability of the material to resist further deformation beyond its yield point. A stress-strain curve is an important tool in designing and analyzing materials and structures subjected to different types of stress. It provides valuable information on the mechanical behavior of materials under other conditions. Factors Affecting Stress And StrainVarious factors can influence the stress and strain experienced by a material or a structure. Some of the key factors that can affect stress and strain include:

Understanding the factors that can affect stress and strain is important in designing and analyzing materials and structures that can withstand different types of stress and loading conditions. Applications Of Stress And Strain

The concepts of stress and strain have many applications in many fields, including materials science, engineering, and physics. Some of the key applications of stress and strain include:

Overall, the concepts of stress and strain are fundamental to many fields and applications, and understanding their behavior is critical in designing and analyzing structures and materials for specific applications. Conclusion

In conclusion, stress and strain are important concepts essential in understanding the mechanical behavior of materials and structures. Stress refers to the internal forces material or structure experiences due to an external load or force. In contrast, strain refers to the resulting deformation or displacement of the material or structure. There are different types of stress and strain, including tensile, compressive, and shear stress and strain, each of which produces a specific type of deformation in the material or structure. Stress and strain are typically graphically represented using a stress-strain curve to obtain crucial information on a material's mechanical behavior under varying loading conditions. This curve illustrates the relationship between stress and strain and is a valuable tool for comprehending how materials will react to different types of loading. Factors that can affect stress and strain include material properties, applied load, temperature, rate of loading, and geometry, among others. Understanding the factors affecting stress and strain is critical in designing and analyzing materials and structures that withstand different loading conditions. The concepts of stress and strain have many applications in many fields, including materials science, engineering, physics, biomechanics, manufacturing, and geology. Understanding stress and strain is essential to designing and analyzing structures and materials for specific applications. Hooke's law is a fundamental principle in stress and strain analysis. It postulates that the strain developed in a material is proportional to the stress exerted on it as long as the stress does not exceed the elastic limit. This law offers a straightforward approach to predicting how materials behave under various loading conditions. To put it briefly, comprehending stress and strain concepts is crucial for understanding the mechanical properties of structures and materials. Their understanding is critical in designing and analyzing materials and structures for specific applications. They have many applications in many fields, including materials science, engineering, physics, biomechanics, manufacturing, and geology.

Next TopicDifference between

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share