Fermentation DefinitionFermentation is a metabolic process that converts sugars and carbohydrates into energy, producing organic acids, gases, or alcohol as byproducts. It is a form of anaerobic respiration, which means that it occurs in the absence of oxygen. The process is carried out by microorganisms such as yeast, bacteria, and fungi, which convert sugars into energy through a series of chemical reactions. Fermentation has been used for centuries to preserve food and produce fermented foods and beverages. The most common fermented foods include yogurt, cheese, bread, beer, wine, pickles, sauerkraut, and kimchi. These foods are produced through controlled fermentation, in which specific microorganisms are introduced to the food to convert the sugars into energy, forming lactic acid, acetic acid, or ethanol. The process of fermentation is an important aspect of food science and technology, as it allows for food preservation, increases shelf life, and improves the nutritional value and taste of food. The organic acids produced during fermentation help preserve the food and contribute to the food's flavour and aroma. Fermentation also plays an important role in the production of biofuels, as it allows for the conversion of biomass into ethanol, which can be used as a renewable energy source. Additionally, fermentation produces industrial chemicals, such as organic acids, amino acids, and vitamins. The process of fermentation is a complex series of reactions depending on the type of microorganism used, the type of sugar or carbohydrate being fermented, and the conditions of the fermentation process, such as temperature, pH, and oxygen levels. The microorganisms used in fermentation can be naturally occurring or can be specifically selected for their ability to produce a desired product.

Several key factors must be considered to control the fermentation process and ensure that it is carried out safely and controlled. These include temperature, pH, oxygen levels, and the presence of other microorganisms that may compete with or interfere with the desired microorganisms. Proper sanitation and sterilization techniques must also be used to prevent the growth of unwanted bacteria or other microorganisms that may compromise the quality of the fermented product. Fermentation is a complex process that requires careful control and monitoring to ensure it is carried out safely. Several key factors must be considered to maintain a successful fermentation, including temperature, pH, oxygen levels, and the presence of other microorganisms. Temperature is a critical factor in fermentation, as it directly affects the microbial growth rate and metabolic activity. The ideal temperature range for most fermentations is between 20°C and 30°C. This can vary depending on the microorganisms involved and the product being produced. If the temperature is too high, the microorganisms may produce off-flavours or other unwanted byproducts or even be killed entirely. If the temperature is too low, the fermentation may proceed too slowly, resulting in reduced yields or poor product quality. pH is another important factor that must be carefully controlled during fermentation. The pH of the fermentation medium affects the rate of metabolic activity and the growth of the microorganisms involved. Most microorganisms prefer a neutral pH between 6.0 and 7.0, varying depending on the specific microorganisms involved. If the pH becomes too low or too high, the microorganisms may become stressed, resulting in reduced yields or poor product quality. Oxygen levels also play a critical role in the fermentation process, as they affect the rate of metabolic activity and the growth of the microorganisms involved. Some microorganisms are facultative anaerobes, meaning they can grow in either anaerobic (oxygen-free) or aerobic (oxygen-rich) environments. In contrast, others are strictly anaerobic and require an oxygen-free environment to grow. Proper control of oxygen levels is essential to ensure that the desired microorganisms can grow and produce the desired product. The presence of other microorganisms is also a critical factor to consider during fermentation, as they may compete with or interfere with the desired microorganisms. Proper sanitation and sterilization techniques must be used to prevent the growth of unwanted bacteria or other microorganisms that may compromise the quality of the fermented product. This is particularly important in food fermentation, where harmful bacteria or other pathogens could risk human health. To ensure the success of a fermentation process, several key factors must be considered and carefully controlled, including temperature, pH, oxygen levels, and other microorganisms. Proper sanitation and sterilization techniques must also be used to prevent the growth of unwanted bacteria or other microorganisms that may compromise the quality of the fermented product. By carefully controlling these factors, the fermentation process can be carried out safely, leading to a high-quality fermented product with improved sensory properties and increased shelf-life. Industrial Application of "Fermentation"Fermentation is a biological process in which microorganisms such as yeast and bacteria convert carbohydrates into organic acids, gases, or alcohols. This process has many industrial applications and is crucial in many industries, including food and beverage production, pharmaceuticals, and biotechnology.

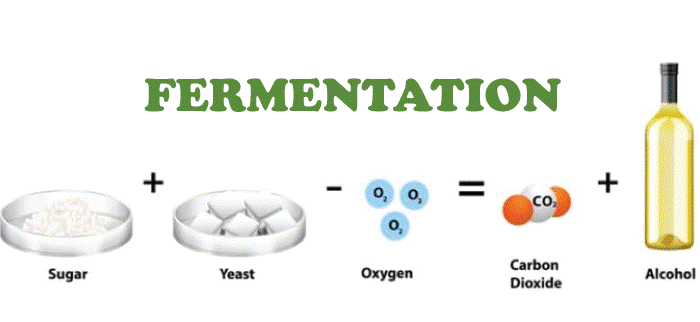

Fermentation has various industrial applications, from food and beverage production to pharmaceuticals and biotechnology. This process plays a crucial role in many industries and offers a sustainable, environmentally friendly solution to many of our world's challenges today. With continued advancements in fermentation, this process will likely continue to play a significant role in shaping the future of our world and improving the lives of people around the globe. Process of FermentationFermentation is a biological process involving converting sugars into organic acids, gases, or alcohols by microorganisms such as yeast and bacteria. Fermentation is essential for producing many food and beverage products, such as bread, beer, wine, cheese, and yogurt. It is also used to produce biofuels, antibiotics, and biodegradable plastics.

The first step in fermentation is introducing microorganisms, such as yeast or bacteria, into the substrate, which is typically a sugar-rich solution. The microorganisms consume the sugars and produce organic acids, gases, or alcohols as waste products. The specific end-product produced depends on the type of microorganism used and the conditions under which the fermentation occurs. One of the key factors that affect the outcome of fermentation is temperature. For example, in bread production, the dough is kept at a warm temperature to encourage the yeast to ferment the sugars and produce carbon dioxide, which causes the dough to rise. Similarly, the temperature must be kept within a certain range in beer production to allow the yeast to ferment the sugars and produce alcohol and carbon dioxide. Another important factor that affects fermentation is the presence of oxygen. Some microorganisms, such as yeast, require oxygen to ferment, while others, such as lactic acid bacteria, carry out fermentation in anaerobic conditions. The type of microorganism used and the presence of oxygen determine the conditions under which the fermentation must occur. In addition to temperature and oxygen, the pH of the substrate also plays an important role in the fermentation process. The optimal pH for fermentation varies depending on the type of microorganism used. Maintaining the pH within the optimal range is important for the process to proceed efficiently. This can be achieved by adding buffers or adjusting the pH with a base or an acid. The end product of fermentation is typically influenced by the type of microorganism used and the conditions under which the fermentation is carried out. For example, in bread production, yeast converts the sugars in the dough into carbon dioxide, which causes the dough to rise. In the production of beer, yeast converts the sugars in the malt into alcohol and carbon dioxide, creating the characteristic flavour and carbonation of the beer. Similarly, in the production of cheese and yogurt, specific strains of bacteria are used to ferment the milk, producing the characteristic flavour and texture of these products. Finally, fermentation is typically stopped by either reducing the temperature or removing the substrate, such as by filtering or centrifugation. This prevents the microorganisms from consuming added sugars and allows the end product to be collected.

Next TopicFever Definition

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share