Friction DefinitionFriction is the force that prevents solid surfaces, fluid layers, and material components from sliding past one another. There are numerous types of friction:

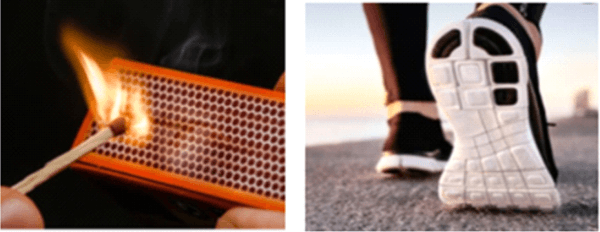

Emotional kinetic energy is converted by creating friction between two surfaces to thermal energy (that is, it converts work to heat). This characteristic can have serious repercussions, as demonstrated by the utilization of friction produced by rubbing two pieces of wood together to start a fire. Friction is a part of tribology. Kinetic energy is converted into thermal energy whenever there is motion accompanied by friction, such as when a viscous fluid is stirred up. Numerous types of friction have a severe side effect called wear that can impair performance or harm components. Friction is both desired and essential for traction and enabling movement on the ground. Most ground vehicles rely on friction for acceleration, deceleration, and direction changes. A sudden lack of traction can cause accidents and a loss of control. Friction alone is not a fundamental force. Dry friction is a result of a combination of surface contamination, surface deformation, surface roughness, and inter-surface adhesion. Because of the intricacy of these interactions, empirical methods must be utilized for analysis and theory building since it is not practical to compute friction from fundamental principles. Work against friction is path dependent since it is a non-conservative force. Mechanical energy is not conserved when there is friction because a portion of kinetic energy is constantly transformed into thermal energy. History:The causes and solutions to conflict piqued the curiosity of the Greeks, especially Aristotle, Vitruvius, and Pliny the Elder. It is simpler to advance the motion of a moving body than to move a body at rest, according to Themistius, who stated this around 350 A.D. He was aware of the distinctions between static and kinetic friction. Leonardo da Vinci, a pioneer in tribology, discovered the traditional rules of sliding friction in 1493; however, the laws he recorded in his notebooks were never published and were therefore unknown. The three laws of dry friction that Guillaume Amontons discovered again in 1699 are commonly referred to as Amonton's three laws. Amontons described friction in terms of surface waver and the force required to lift the mass that forces the surfaces together. By measuring the angle of repose of a mass on an inclined surface and establishing the first distinction between static and kinetic friction, Bernard Forest de Bélidor & Leonhard Euler built upon this idea in 1750. John Theophilus Desaguliers originally understood the importance of adhesion in friction in 1734. Surfaces cling together due to microscopic forces; he suggested that friction was required to separate the adhering surfaces. Charles-Augustin de Coulomb furthered our understanding of friction (1785). Coulomb focused on four main aspects while studying friction:

Coulomb looked more into how sliding velocity, temperature, and humidity affected friction to decide between the several hypotheses for the nature of friction that had been put out. Although Johann Andreas von Segner first stated this distinction in 1758, Coulomb's friction law (see below) distinguishes between static and dynamic friction. Pieter van Musschenbroek (1762) employed the surfaces of fibrous materials with intertwined fibers to describe the impact of the time of repose. The duration of this operation, during which the friction rises, is finite. A problem with Amontons' and Coulomb's ideas was pointed out by John Leslie (1766-1832): if friction comes from a weight being pushed up an inclined plane of consecutive asperities, why isn't it balanced by descending the opposite slope? The role of adhesion, as suggested by Desaguliers, which should generally have the same tendency to accelerate as well as delay the motion, was met with equal skepticism by Leslie. According to Leslie, friction should be viewed as a time-dependent process of flattening and pushing asperities, which produces new impediments in previously unobstructed cavities. Arthur Jules Morin made the distinction between sliding and rolling friction in 1833. Osborne Reynolds created the viscous flow equation in 1866. Fleeming Jenkin and J. A. Ewing 1877 studied the continuity between static and kinetic friction. This concluded that the traditional empirical friction model (static, kinetic, and fluid) is still used in engineering today. The physics of friction was the focus of much research in the 20th century. Frank Philip Bowden and David Tabor's 1950 study revealed that just a very small portion of the apparent area represents the entire area of contact between surfaces at the microscopic level. With pressure, the asperities' real area of contact grows. Scientists were able to demonstrate that, at that size, dry friction is a function of the contact area and the inter-surface shear stress thanks to the atomic force microscope, which was developed to examine friction at the atomic level. Along with Amonton's first law (below), these two findings offer a macroscopic explanation for the link between normal force and the static frictional force between dry surfaces.

Dry Friction Laws:From the 15th through the 18th century, experimentation revealed the fundamental characteristic of sliding (kinetic) friction, which was then stated as three empirical laws:

The applied load immediately affects the frictional force.

The apparent area of contact has no bearing on the frictional force.

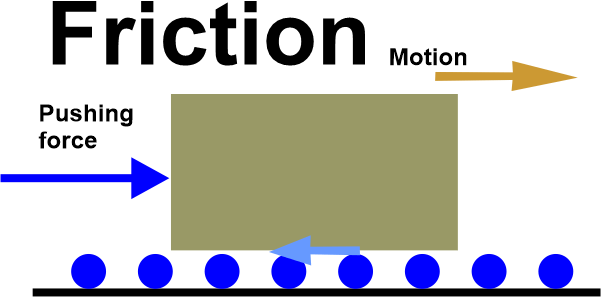

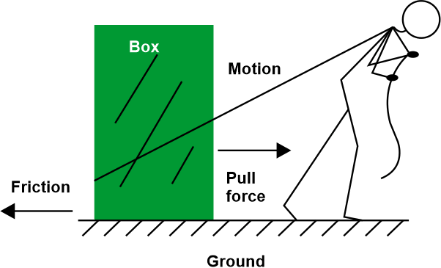

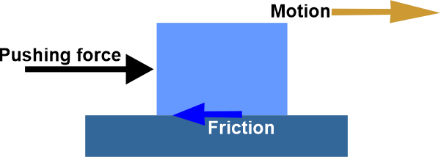

Slider velocity has no bearing on kinetic friction. Dry Friction:Dry friction prevents the relative lateral motion of two solid surfaces from moving too far apart. The two regimes of dry friction are kinetic friction, often called sliding friction or dynamic friction, between moving surfaces and static friction between stationary surfaces (also known as "stiction"). The Coulomb friction model, which carries the name of Charles-Augustin de Coulomb, allows one to compute the force of dry friction roughly. It follows the following model:

Where,

The direction of the frictional force that acts on a surface is opposite to the motion that the surface would experience if there were no friction, and the Coulomb friction may have any value between zero to In the case of static or kinetic friction, this same friction force has always been applied to counteract actual or potential movement between two surfaces. For instance, a curled stone sliding along ice encounters a kinetic force that slows it down. For an example of potential movement, When a car accelerates, the drive wheels suffer a frictional force directed forward; if this force weren't present, the wheels would spin, and the rubber will slide backward over the pavement. You should note that they oppose the direction of travel of the opposing vehicle, not just the direction of (possibly) sliding between the tire and the road. Static Friction:Surface roughness characteristics at solid surfaces are thought to manifest themselves as static friction at various length scales. As an illustration, static friction can stop an object from slipping on a sloped surface. When two or more items are solid and not moving about one another, they will rub against one another with static friction. In most cases, the coefficient of kinetic friction is lower than the static friction, which is commonly represented as s. As a result, only a small portion of the apparent or nominal contact area is a true solid-to-solid contact because of these asperities maintained down to nanoscale dimensions. For typical Amonton-Coulomb type friction, the linearity among static frictional force with normal force is produced by the asperity deformation and results in the linearity among applied loads with true contact area.

Before an object may move, there needs to be a force exerted to overcome the static friction force. The sum of the normal force and the coefficient of static friction gives the maximum amount of friction that can exist between the two surfaces before sliding starts: The friction force can be any value between zero and Fmax when no sliding action occurs. A frictional force of comparable size and directed in the opposite direction oppose any force less than Fmax that tries to slide one surface over the other. Static friction is overcome by any force greater than Fmax, which results in sliding. The friction between the two surfaces is then referred to as kinetic friction because static friction is no longer relevant once sliding has started. But even when there is no natural static friction, apparent static friction can be seen. The resistance that keeps an automobile wheel from slipping as it rolls over the ground is an example of static friction. While the tire patch in contact with the floor is stationary concerning the wheel in motion, there is static friction instead of kinetic friction. Wheel friction turns into kinetic friction when sliding occurs. The idea behind anti-lock braking is to let a locked wheel start rotating again so that the vehicle maintains static friction. Limiting friction is a word that is occasionally used to describe the highest static friction value that can exist when motion is imminent. Kinetic Friction:When two things move for one another and rub against one another, it is known as kinetic, dynamic, or sliding. The term "kinetic friction coefficient" (abbreviated "k") refers to the fact that it is often smaller for a given set of materials than the term "static friction coefficient." Yet, Richard Feynman states, "it is very difficult to prove any difference with dry metals." The friction force between two surfaces causes an oscillating or vibrating system's Coulomb damping once sliding has started. This friction force is created by multiplying the normal force by the coefficient of kinetic friction. As kinetic friction grows, new models are starting to demonstrate how static friction can decrease. Today, it is widely accepted that chemical bonds between surfaces, rather than interconnecting asperities, are often the primary cause of kinetic friction; however, roughness effects still play a significant role in many other situations, as in the friction between rubber and a surface like a road. For micro- & nanoscale objects wherein surface area forces predominate over inertial forces, surface roughness & contact area have an impact on kinetic friction. Thermodynamics can be used to explain how kinetic friction at the nanoscale first appeared. Since the thermodynamic surface energy is present on all surfaces, labor is required to create a new surface, while energy is released as heat when the surface is removed. A new surface develops at the back of a genuine sliding contact, and the old surface vanishes at the front. As a result, a force is needed for the back of the contact, and heat from the friction is released at the front. The Atomic Level of Friction:Designing nanomachines is difficult because it is difficult to predict the forces needed to drive atoms past one another. An atomic force microscope was modified to drag a cobalt atom and a carbon monoxide molecule across copper and platinum surfaces in an environment of extreme vacuum and almost absolute zero temperature (5 K). For the first time, a single atom could be moved over a surface in 2008, and the forces needed to do so could be measured. The Coulomb Model's Drawbacks:The Coulomb approximation is based on the assumptions that only a small fraction of a surface is in atomically close touch, that this contact area is proportionate to the normal force, and that the frictional force is proportionate to the normal force, regardless of the contact area. The Coulomb approximation is, at its core, an empirical theory. It serves as a generalization of the approximate result of a very complex physical interaction. The approximation's adaptability and ease of use are its main advantages.

Even though there is some nonlinearity in the relationship between normal force & frictional force, the Coulomb approximation offers a reliable friction model for analyzing a wide range of physical systems. When the surfaces are joined, coulomb friction is greatly reduced. In this case, the contact area may significantly influence the frictional force. This is why some drag racing tires are sticky. Although the fundamental physics underlying friction is complex, the correlations are precise enough to be helpful in many applications. "Negative" Friction Coefficient:The friction that an atomic force microscope stylus experiences when moving across a graphene sheet while oxygen has been deposited onto the material was described in the journal Nature in October 2012. As of 2012, just one study had shown that, in the low-load domain, the coefficient of friction could be effectively negative, which means that a reduction in normal force causes an increase in friction. This goes against common sense, which dictates that as normal force increases, friction also rises. Coulomb Model Numerical Simulation:Despite being a streamlined friction representation, the Coulomb model has various uses in numerical simulations, including granular material and multibody systems. Although particular techniques must be developed to effectively numerically integrate mechanical systems with Coulomb friction and bilateral or unilateral contact, even its most basic expression captures the basic effects of sticking and sliding that are necessary for many practical applications. Coulomb friction can produce nonlinear phenomena, including the so-called Painlevé paradoxes. Dry Friction and Instability:Mechanical systems that behave predictably without friction might experience a variety of instabilities when friction is present. Thermo-elastic instabilities, material expansion due to heat generation during friction, and pure dynamic effects of sliding two elastic materials can all contribute to these instabilities (the Adams-Martins instabilities). George G. Adams and Joo Arménio Correia Martins first identified the latter in 1995 for smooth surfaces, and they later did so for irregular rough surfaces. Brake squeal and the "song" of a glass harp, phenomena involving stick and slip, are hypothesized to be caused in particular by friction-related dynamical instabilities. These phenomena are described as a decline in friction coefficient with velocity. One notable instance is the self-oscillation of strings of bowed instruments, including the violin, cello, hurdy-gurdy, erhu, etc. Frictional instabilities can lead to new self-organized structures at the sliding contact, including in-situ formed tribofilms, to lessen wear and friction in self-lubricating materials. Fluid Friction:Fluid friction happens when fluid layers move about one another. Viscosity refers to this internal flow restriction. In common parlance, a fluid's viscosity is defined as its "thickness." In this way, honey is "thick" and has a higher viscosity than water, which is "thin" and has a lower viscosity. The fluid is more easily deformed or moved when it is less dense. Since all essential fluids (apart from superfluids) have some shearing resistance, they are all dense. The idea of an inviscid fluid, also known as an ideal fluid, is useful for teaching and explaining purposes since it offers no resistance to shearing and is, therefore, not vicious. Lubricated Friction:When a fluid separates two solid surfaces, it causes friction, known as lubricated friction. Lubrication reduces wear on one or both surfaces that are moving close to one another by sandwiching a substance known as a lubricant between them. Ample lubrication enables equipment to run continuously and smoothly, with minimal wear and no excessive strains or bearing seizures. Due to the lubricating fluid's frictional viscous barrier to motion, the applied load is typically borne by pressure created within the fluid. Metal or other components may rub against one another destructively when lubrication fails, producing heat and possibly damaging or failing the system. Skin Friction:Skin friction is the outcome of a fluid's interaction with a body's skin and is inversely proportional to the area of the body's surface that is in contact with the fluid. The drag equation is followed by skin friction, which increases with the square of the velocity. The boundary layer around the item experiences viscous drag, which results in skin friction. A moving body can be shaped to allow for smooth flow, much like an airfoil, to reduce skin friction. The second technique reduces the moving object's length and cross-section to the greatest extent possible. Internal Friction:The force limits motion among a solid substance's parts as it deforms, known as Internal friction. A permanent modification to an object's internal molecular structure is called plastic deformation in solids. Both a force being applied and a temperature change could cause this change. Strain is the change in an object's form. Stress is the driving force behind it. In solids, elastic deformation is a reversible alteration to the object's interior molecular structure. Internal forces work against the applied force when deformation takes place. Stress only sometimes results in long-lasting change. When a force is applied, if it is not too great, the object may reach a new equilibrium situation and revert to its original shape. If the imposed stress is not too strong, these opposing forces may entirely resist the force. Elasticity or deformation is the term used to describe this.

Radiation Friction:Einstein postulated the possibility of "radiation friction"-a force that would prevent the matter from moving-in 1909 due to light pressure. The pressure that radiation will apply to the plate's two sides is stated in his writing. If a plate is at rest, equal pressure forces are applied to the two sides. It applies pressure backward, pushing the front surface more than the back. On the other hand, if it is moving, the front surface will reflect more radiation than the back surface because it is further forward during the motion. As a result, the sum of the two forces results in a force that opposes the plate's motion and grows stronger as the plate's velocity increases. Other Types of Friction:

A wheel or other circular object cannot move along a surface due to distortions in the object or surface, known as rolling resistance. The rolling resistance that results from moving a car's tires on the road is one of the most prevalent types of rolling resistance, producing heat and sound. In general, rolling resistance exerts less force than kinetic friction does. The coefficient of rolling resistance typically has values of 0.001.

Any wheel with brakes can generate a sizable amount of retarding force, often to slow down and stop a machine or moving piece of equipment. In contrast to rolling friction, which has a small coefficient of friction, braking friction has a large coefficient because the materials used in brake pads are engineered to make it that way.

Electrostatic charge can accumulate when dissimilar materials are rubbed against one another, which can be dangerous if combustible gases or vapors are present. Explosions may occur when the static buildup is released due to the explosive mixture starting to ignite.

When a belt is coiled around a pulley, and one end is pulled, forces are applied to the other end of the belt, which is when belt friction is visible as a physical property. When doing simple activities, sailing teams and mountain climbers commonly understand belt friction. In real-world applications, the theoretical tension calculated by the belt friction equation acting on the belt/rope can be compared to the maximum tension the belt can support. To prevent the pulley from slipping, the apparatus designer can use this information to calculate how many times the belt or rope needs to be looped around the pulley. Reducing Friction:Devices:Devices that convert sliding friction into a much smaller type of rolling friction include tires, wheel bearings, roller bearings, air cushions, and other fluid bearings. High-molecular-weight grades are typically selected for their superior wear resistance for heavy loads or crucial bearings. Various thermoplastic materials, including nylon, HDPE, and PTFE, are frequently employed in low-friction bearings. They are particularly helpful because of coefficient of friction decreases as the applied weight increases. Lubricants:Tribology is the field of study that deals with friction and lubrication. A lubricant, such as oil, water, or grease, is frequently used to reduce friction by sandwiching it between two surfaces. This method frequently results in a significant decrease in the coefficient of friction. When lubricants and science are combined, particularly for industrial or commercial goals, the result is known as lubricant technology. Graphite exhibits the newly discovered phenomenon known as superlubricity, characterized by a significant reduction in friction between two moving objects that approaches zero values. Frictional energy would still be lost, albeit in extremely small amounts. The use of sound as a lubricant, or acoustic lubrication, allows for friction to be reduced without the need for thin, turbulent fluid or powdered materials like graphite and talc. Adding micro-scale vibration to one of the pieces can reduce friction between two moving parts. This can be vibration noise, referred to as dither or sinusoidal vibration, utilized in ultrasound-assisted cutting. Frictional Work:Static friction does not impact contact between two surfaces since there is never a movement between the surfaces. Kinetic friction always moves in the direction counter to the motion and produces negative work in the same frame of reference. However, friction can have a beneficial effect in other frames of reference. One can observe this by putting a large box on a rug and immediately dragging it on it. In this instance, the box moves forward about the frame of reference where the floor is stationary but slides backward about the rug. Because of kinetic friction between the box and rug, the box accelerates in the exact direction as it goes, creating positive work.

Frictional action can result in heat, distortion, and wear, all of which can change the characteristics of the contact surface (even the coefficient of friction between the surfaces). This may be advantageous, similar to polishing. As in the friction welding process, materials are mixed and joined by friction. When the amount of work caused by frictional forces reaches unacceptably high levels, the mated sliding surfaces begin to erode or wear excessively. Frictional forces are worn out more quickly by harder corrosion particles trapped between mating surfaces while in relative motion (fretting). Surfaces worn by use and friction can cause an object's fit and surface polish to degrade to the point that it is no longer usable. For instance, severe wear from frictional work may cause bearing seizure or failure.

Next TopicGravitation Definition

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share

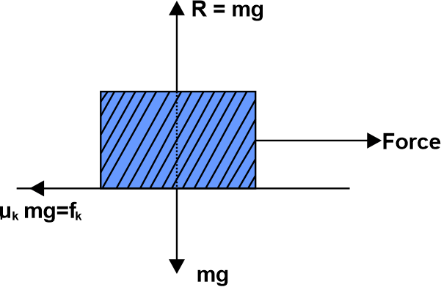

is the amount of friction that one surface creates with the other. It is opposite to the net applied force and parallel to the surface.

is the amount of friction that one surface creates with the other. It is opposite to the net applied force and parallel to the surface. is the coefficient of friction, a characteristic of the contacting materials that can be empirically measured.

is the coefficient of friction, a characteristic of the contacting materials that can be empirically measured. is the normal force, oriented perpendicular to the surface, that each surface exerts on the other.

is the normal force, oriented perpendicular to the surface, that each surface exerts on the other. . As a result, in the static scenario, the frictional force balances the net force that would otherwise tend to generate motion between the surfaces, which is exactly what it needs to be to prevent such motion. In this instance, the Coulomb approximation gives a threshold level for this force above that motion would begin rather than an estimate of the same frictional force. Traction is the name for this greatest force.

. As a result, in the static scenario, the frictional force balances the net force that would otherwise tend to generate motion between the surfaces, which is exactly what it needs to be to prevent such motion. In this instance, the Coulomb approximation gives a threshold level for this force above that motion would begin rather than an estimate of the same frictional force. Traction is the name for this greatest force.