Machine DefinitionWhen referring to equipment that automatically sequences prints, the word "machine" is often used. The word "machine" is used to describe tools that continuously carry out the same duties. They are frequently programmable, capable of learning on their own, and able to enhance their performance. The word "computer" is used in a variety of situations, including manufacturing, robotics, and computers.

What is MachineThe Latin term machina, which meaning "tool of torment," is the source of the English word "machine." Several objects in the world have been described using the word machine. It can also be used to describe any kind of mechanism or apparatus that changes inputs into outputs. Computers, robots, and automobiles are just a few examples of the many uses for which machines are used in today's society. A computer programme or piece of software that carries out a series of operations automatically and without human input is also referred to as a machine. The meaning of machine: Machines are those devices that allow users to exert little amounts of force to absorb large amounts of force or produce rapid motion. We can also alter the direction in which the machine's force acts.

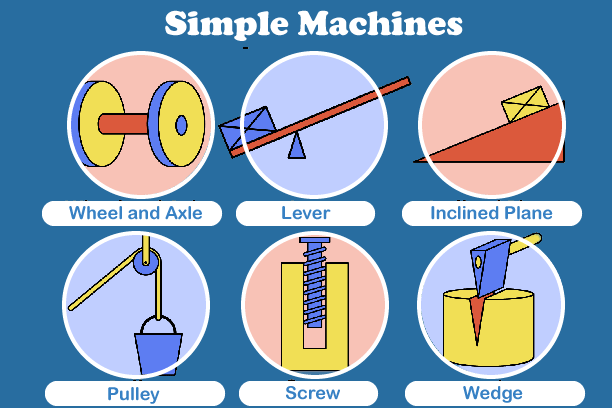

Work Done by a MachineThe machine's efficiency is equal to (Work completed by the machine/Work supplied to the machine)/100. Some researches are like: An ideal machine is one that functions at 100% efficiency. The existence of frictional forces prevents any machine in the world from being an ideal machine. As a result, a portion of the labor the machine is given to complete is spent working against the force of friction. History of MachinesThe human hand turns the power and movement of the hand axe, which is formed by chipping flint into a wedge, into a transverse splitting force and movement of the workpiece. The earliest of the six traditional simple machines-the wedge, on which most machines are based-is the hand axe. The inclined plane (ramp), which has been used to transport heavy items since ancient times, is the second-oldest basic machine. In the historical Near East, four further basic machines were created. By the fifth millennium BC, the wheel and wheel-and-axle mechanism were created in Mesopotamia (now Iraq). Over 5,000 years ago, in the Near East, a simple balance scale and an ancient Egyptian device both used lever mechanisms to move heavy things. First crane machine used around 3000 BC, shaduf pumping equipment. Mesopotamia, and ancient Egyptian technology around 2000 BC. Both used levers. The oldest pulleys were found in ancient Egypt during the 12th Dynasty and in Mesopotamia around 2000 BC. The Neo-Assyrian period (911 BC - 609 BC) saw the first appearance of the screw, the first primitive machine made in Mesopotamia. Three of the six simple machines - the incline plane, the wedge and the lever - were primarily used in the construction of the Egyptian pyramids. Around the 3rd century BC the Greek philosopher Archimedes explored and discussed the following his three simple machines: Archimedes discovered the principle of mechanical superiority in levers. The later Greek philosopher (excluding inclined planes) was able to define his five simple traditional machines and roughly determine their mechanical advantages. Lever, winch, pulley, wedge, and screw are listed by Heron of Alexandria (c. AD 10-75) in his book Mechanics as his five mechanisms capable of "moving a load". It also explains how to make and use it. But the Greeks understood only statics (the balance of forces), not the concept of mechanics (the balance of force and distance) or effort. Types of MachinesMachines come in two kinds - Simple Machines and Complex Machines. Simple MachinesA simple machine is a tool, instrument, or other item that assists humans in performing tasks and has few moving parts. There has been a very long history of the use of simple machines. Simple machines were employed by early humans to push, pull, lift, divide, and crush objects. Simple machines were used by them to carry heavy objects from one place to another, build houses, split firewood, and row rafts across water. Simple machines can be found almost anywhere today. The inclined plane, the wedge, the screw, the lever, the wheel and axle, and the pulley are six examples of primitive machines. Although several may function in a similar manner, these six have distinctive qualities and perform distinctive tasks. Some simple machines might be made up of several different simple machines.

Characteristics of simple machines:

The inclined planeA basic machine with no moving parts is an inclined plane. It's just a surface that slopes evenly. As opposed to if we raised the objects directly upwards, it makes it simpler for us to move the objects to higher or lower surfaces. According to legend, the ancient Egyptians transported large stones on inclined planes in order to construct the pyramids. Inclined refers to an end that is raised or raised at one end. A piece of wood leaning against a higher point or a manufactured structure both qualify as inclined planes. Ramp is another name for an inclined surface. A horizontal side characterizes an inclined plane (the distance from the lower end of the slope to the base of the vertical). There is a vertical side as well (from the base up to the top of the sloped surface). Trade-offWith this straightforward device, there is a cost. A person must push or drag an object a greater distance yet with less effort if the slope is gradual. A person must exert more effort to move an object a very small distance when the slope is steep. Mechanical benefitWe can better grasp the mechanical benefit of inclined planes by considering trade-offs. For instance, a moderate slope has a bigger mechanical advantage since it requires less force to move an object up or down the slope. Accessible ramps and home roofs are two excellent examples of inclined planes. A WedgeSimply said, a wedge is a triangular object that is frequently formed of metal, wood, stone, or plastic. On one end, it is thick, while on the other, it tapers to a narrow or sharp edge. Technically, the object moves on an inclined plane, or on two inclined planes joined together to form a triangle. To make a handle easier to operate, a wedge may be fastened to it. The best wedges are your teeth, knives, axes, and nails. Wedge uses include the following:

Single and dual wedgesThere are two types of wedges: single and double. Each carries out a tad bit diverse work. A chisel is a single wedge, but an axe is a double wedge. Trade-offA wedge can accomplish more work with less effort depending upon how longer and narrower (and therefore sharper) it is. One requires greater force to perform the task if the wedge is shorter and has a wider angle at the tip. When a wedge is longer and has a narrower tip, its mechanical advantage is greater. The use of wedges dates back millions of years. To hunt (like spears), cut and shape trees, and carve stones, early people utilised wedges made of hard pebbles and stones. Modern cars and aircraft both make advantage of the wedge design. You'll notice that the noses of trains, fast cars, speedboats, and aircraft are pointed. Because of this, they can cut through the air (air acts as a resistance). Aerodynamics is the study of how air flows around pointed objects. ScrewAn inclined plane wrapped around a cylinder is all that a screw is. You can visualise it as a cylinder with a head (solid top) at one end and a pointed tip (like a nail) at the other in order to better understand it. Its surrounding ridges are more significant. The thread is the proper name for the ridges (or grooves) that surround the shaft or cylinder. The screw serves as a basic machine Each screw has a constant distance between threads, although some screws have a varied spacing. A pitch is the measurement of the space between threads. Things can be held together with the use of screws. They are able to push or pull an object into place. They can be used to tighten objects as well as raise hefty objects. Screw and nail They're not the same at all. A screw has ridged all the way around its shaft, unlike a nail. The ridges on the screw provide a lot of friction and resistance, making it more difficult to drive a screw into a piece of wood. A screw-driver must turn the screw in a circular motion in order to drive it into the wood. Other types of screws:

Illustrations of screwsBolts, screws, bottle tops, guitar tuners, light bulbs, faucet taps, and cork openers are a few excellent examples of screws. Mechanical benefitThe length and thickness of the screw and the distance between the threads both affect mechanical advantage. The mechanical advantage increases with the thread spacing. A narrower thread spacing makes it simpler to insert a screw into a surface. There are more turns but less work. Drilling a screw into an object is more difficult if the gaps between the threads are bigger. There are fewer twists, but it takes more work. LeverA plank or ridged beam that may freely spin about a pivot is what makes up a lever. It is ideal for transporting or lifting objects that are hefty. There are numerous examples of this practical simple machine. The seesaw, crowbar, fishing line, oars, wheelbarrows, and garden shovel are all effective examples of levers. Components of a lever The bar or beam, the fulcrum (the pivot or turning point), the effort (or force), and the load are the four crucial components of a lever. The three lever classes The arrangement of the lever's components is not constant. There may be multiple locations on the plank where the load (L), fulcrum (F), and effort (E) are. 1. Lever of class one: Between the effort and the load in this class is where the Fulcrum is located. If the load is placed closer to the fulcrum, the mechanical advantage increases. Seesaws, boat oars, and crowbars are a few instances of Class One Levers. 2. Lever of class two: Between the effort and the fulcrum in this class is the load. If the load is near to the fulcrum, the mechanical advantage is greater. Wheelbarrows are an example of a Class Two Lever. 3. Three-class lever: The effort in this class is between the Load and the Fulcrum. If the effort is more closely matched to the load, the mechanical advantage increases. A garden shovel is an illustration of a Class Three Lever. Wheel and AxleTwo circular objects-a larger disc and a smaller cylinder linked at the center-make up this straightforward device. The wheel is the largest disc. The axle is the shorter cylindrical component or rod. On occasion, the axle may have two wheels attached to each end. A wheel or an axle by itself do not constitute a simple machine. To be said to as a basic machine, they must be connected. If you examine a wheel and axle's operation carefully, you will see that it functions like a class one lever. In this case, spinning the axle will result in output at the opposite end. Where the axle connects to the wheel is the fulcrum. There are two ways the wheel and axle function: Let's use a screwdriver as an example of the force imparted to the wheel. When you exert force on the wheel (the handle), the wheel spins and multiplies the effort, increasing the axle's (the shaft's) output force. The doorknob is a basic device Another illustration of a wheel and axle is a doorknob. Just the doorknob has control over the locking mechanism, which is located within the door. We can turn the wheel to open the door instead of trying to turn the axle because it will be more difficult. Force imparted to axle:Now let's have a look at a windmill as well. If you exert force on the axle, the effort is multiplied by the number of blades on the wheel, increasing the distance travelled. The reason for this is that the wheel has a bigger surface area than the axle. Like that of a ceiling fan. The larger wheel (fan blades), which is powered by the axle, generates the appropriate output. The Wheel and Axle are used in autos and are ideal for spinning turbines and fans. As you spin a car's steering wheel, for instance, the axle multiplies your effort, which causes the wheels to turn more. PulleyYou may have seen the raising of the school flag using a basic pulley, that is feasible. The pulley at the top of the pole turns when you pull downward on the rope, raising the flag. Pulleys shift the force's direction. A pulley simple machine: what is it? A pulley is nothing more than a wheel with a groove and a rope inside. It is also known as a sheave or a drum. Because it keeps the rope in place, the groove is crucial. Heavy objects are raised or lowered with it. The object to be hoisted is secured to one end of the rope using a pulley. Pulling the rope downward exerts a force on the other end. The weight is pulled upward at the other end of the rope-driven wheel by the downward force. Different pulleys:Three different kinds of pulleys exist. The combination of the wheel and ropes determines which pulley system is used.

It is the most basic type of pulley. Basic pulleys cannot be moved since their axles are set in place. The wheel is fixed in place, but the rope can move within the pulley's groove. A nice illustration is the wheel on the flagpole at your school.

A load is fastened to a movable pulley, and the two of them can travel in different directions. With this kind, the rope's one end is fastened to a stationary fixed point. Lifting a load requires less work when using a moving pulley.

It is a collection of pulleys made to make lifting loads that weigh only half as much as they should be effortless. Construction sites frequently use cranes of this type to lift massive steel and concrete objects. A Block and Tackle is a good illustration of a compound pulley.

Next TopicMeningitis Definition

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share