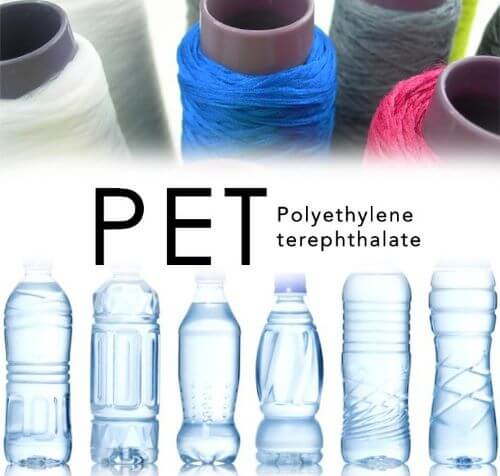

What is the full form of PET?PET: Polyethylene TerephthalatePET stands for Polyethylene Terephthalate. It is a type of plastic that is clear, tough and shatterproof and is widely used in the manufacturing of plastic bottles, film packaging, fabrics, moulded parts of automotive, etc. In its natural state, it is very flexible and colourless. However, depending on the processing method, it can be rigid or semi-rigid. PET resembles very much to Polybutylene Terephthalate chemically.

We can say that it is a general-purpose thermoplastic polymer from the polyester family of polymers. Polyester resins have a wide range of properties such as thermal resistance, chemical resistance, mechanical and dimensional stability. These properties make it one of the most recycled thermoplastics. Its recycling symbol is '1'. Key Properties of PET Resin:

Chemical Properties:It is resistant to alcohols, oils, greases, and diluted acids. However, it is less resistant to aromatic hydrocarbons, and diluted alkalis. Besides so many advantages, there are also some limitations of Polyethylene Terephthalate:

PET can be blended with other thermoplastics and thermosets to improve its performance and to use it for different purposes. The purpose of producing its blends is to improve cost-effectiveness and its properties such as mechanical strength, flame retardancy, processability, etc. Major Uses of PET products:

How is PET made?It is made by the polycondensation reaction of the monomers obtained by the esterification reaction between terephthalic acid and ethylene glycol or by the trans-esterification reaction between dimethyl terephthalate and ethylene glycol. In this reaction, the PET is produced in a molten form which can be spun to fibres or moulded into different shapes.

Next TopicFull Forms List

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share