WeldingWelding is a mechanical process used to fuse two metal pieces. We can also join thermoplastics with the help of welding. The process is carried out by heating (high heating) the edges of the two workpieces to melt. The melted pieces are joined together when it cools. We can also apply pressure to create a strong joint. Some welding processes also require a protecting sheath to protect the metal from external environmental factors, such as corrosion and oxidation. Cooling is a natural phenomenon. The welding process does not require any external coolant. The two workpieces, after joining, automatically get cooled in the surrounding temperature.

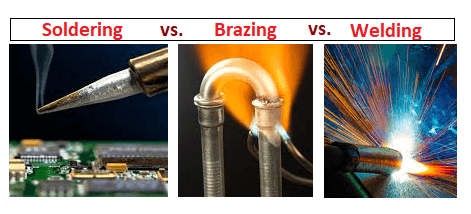

Welding differs from brazing and soldering because it does not require any base metal or filler material to fuse the two workpieces. We will later discuss the differences between these three processes. The welding applications include making transportation tankers, joining thin metal sheets, pipes, tubes, manufacturing of refrigerators, washing machines, etc. Here, we will discuss the following topics: Types of Energy sources of welding History of welding Methods of Welding Safety Issues General applications of welding Soldering vs. Brazing vs. Welding Types of Energy sources of weldingThe energy sources of welding provide heat to fuse the two workpieces. There are various types of energy sources used in welding. It is listed below:

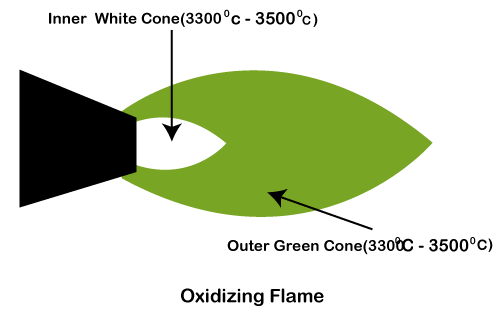

Let's discuss the above energy sources in detail with their applications. Gas flame weldingThe Gas flame releases gas at the heat source. The gas flame is of three types: oxidizing flame, natural flame, and carburizing flame. The oxidizing flame has more oxygen concentration. The carburizing flame has more fuel concentration, while the natural flame has both fuel and oxygen. Let's discuss these three gas flame types in detail. Oxidizing flame It is also called oxyacetylene flame. It is because it a mixture of oxygen and acetylene. The oxidizing flame has two regions, the inner and outer flame. The inner zone of the flame is very bright. The tip of the inner core has a temperature of around 3300 degrees Centigrade. The outer zone of the flame is generally blue, as shown below:

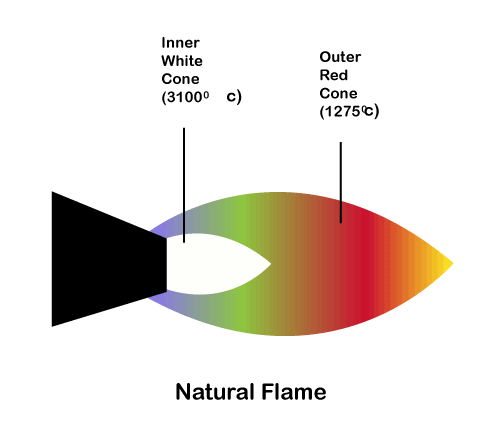

The oxidizing flame is used for welding various metals, such as zinc, manganese steel, etc. Natural flame As the name implies, the natural flame has an equal amount of acetylene and oxygen. The flame produced doe not react chemically with any metal. It also emits very less smoke. The flame has two zones, inner and outer, with color white and blue, as shown below:

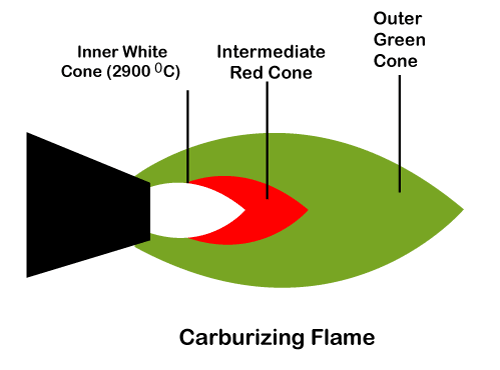

The natural flame is used to weld metals, such as cast iron, stainless steel, etc. Carburizing flame The carburizing flame is also a combination of acetylene and oxygen. But, the concentration of acetylene (fuel gas) here is in excess amount. The flame produced is quite smoky because the flame can chemically react with the metal. The flame has three zones, the inner, middle, and outer zone. These three zones have a white, red, and blue color, as shown below:

The carburizing flame is used to weld metals, such as nickel, carbon steel, etc. Advantages

Disadvantages

Electric arc weldingElectric arc welding is the most used welding source in the industry. Most of the welding methods depend on the electric arc as the heat source. The electric arc produces the prolonged electrical discharge (transmission of electricity in the gas as a medium) used as a heat source to fuse the workpieces. The electric arc melts the end of two workpieces, which fuse when pressure is applied to maintain contact. The electric arc requires power from the AC power supply. It can also operate on the DC (Direct current) supply. It is a crucial welding process used in vehicle manufacturing and steel. Advantages

Disadvantages

Electron beam weldingThe electron beam is produced from the electron gun. The electron beam consists of the electrons accelerated at high speeds using the electric fields. As soon as the electron beam strikes the workpieces, it produced kinetic heat that further causes the metal to melt. The electron beam is generally used to weld different metal workpieces. The kinetic energy produced by the electron beam is converted into heat that acts as a heat source to melt the contact of the workpieces to be joined. It has various applications, such as sealing electrical components, joining dissimilar metals, etc. Advantages

Disadvantages

Ultrasound weldingThe two workpieces are strongly held to create a solid contact before welding. The ultrasound welding is directed on the contact between two workpieces, which creates a solid bond. Ultrasound welding is a process that emits high-frequency ultrasonic acoustic vibrations that acts as a heat source. It is also used for different metal workpieces. The temperature is maintained below the melting point of the materials to prevent any high-temperature exposure during the welding. Advantages

Disadvantages

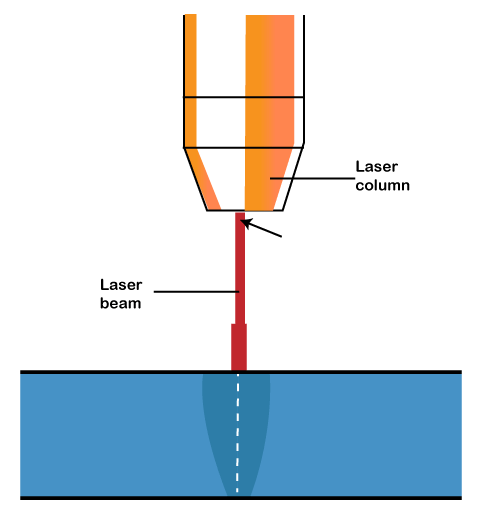

Laser weldingLaser is the light produced based on the stimulation emission of electromagnetic radiation. The advantages of laser include highly monochromatic, high powers, and a wide range of materials. Here, the laser beam acts as a source of contact between the two workpieces.

It is a fast process due to its high speed. It can also produce deep welds in thicker materials. The high power of the laser allows it to focus on even small spots. It can easily penetrate the workpieces by forming a cavity. The highly monochromatic laser beam prevents the molten walls from collapsing. The keyhole thus formed has a high depth to width ratio. Advantages

Disadvantages

Friction weldingAs the name implies, friction used creates heat through mechanical friction between the workpieces. The friction is generated with the help of relative motion to one another. The types of friction welding include rotary friction welding, linear friction welding, etc. It is used in various applications, such as welding of pipes, circular rods, etc. Advantages

Disadvantages

History of welding

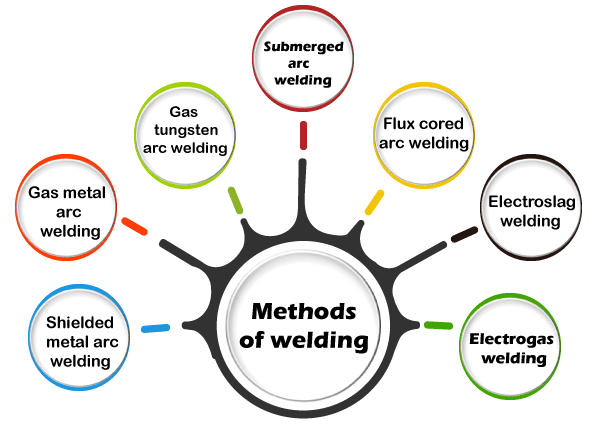

Methods of welding

Shielded metal arc weldingThe shielded arc welding is also known as stick welding. It uses electric arc as the heat source. It requires an electrode covered with flux to weld. The electrode requires energy from the external power supply (AC or DC). When the welding is performed, the flux on the electrode gives off vapor to protect the welded area. It means that flux vapors act as a shielded gas to prevent the weld from the atmospheric contamination. Shielded metal arc welding is one of the most popular welding methods. Advantages

Disadvantages

Gas metal arc weldingGas metal arc welding (GMAW) is also known as MIG (Metal Inert Gas) welding. The apparatus consists of an electric arc (welding heat source) and the workpieces to be joined. The electric arc is generated from the MIG wire electrode that melts the contact between two workpieces to join. The electrode gun and the electric arc release the shielded gas, which forms the shield over the welded contact. It saves the contact from atmospheric contamination. It can operate both on Alternating and constant current sources. The cost of inert gas during the initial days limited the use of gas metal arc welding. But after the use of semi-inert gas carbon dioxide, the welding technique became much popular. It is one of the versatile processes of the welding industry. Advantages

Disadvantages

Gas tungsten arc weldingGas tungsten arc welding is also tungsten inert gas (TIG) welding. As the name implies, the TIG welding process uses the tungsten material in the electrode that produces the weld. During the process, the inert shield gas (such as helium) prevents the electrode and welded area from atmospheric contamination. TIG can also be used to weld non-ferrous or stainless steel materials, such as aluminum copper. Advantages

Disadvantages

Submerged arc weldingSubmerges arc welding (SAW) is also a type of arc welding that requires an electrode to perform welding. A considerable flux is required to protect the metal from contamination. The molten weld needs to be submerged in the flux blanket consisting of various compounds, such as silica, lime, etc. The flux in the molten state provides the current path between the work and the electrode. Advantages

Disadvantages

Flux-cored arc weldingThe flux-cored is also a type of welding that uses an electric arc as the heat source. The welding process can be fully automatic or semi-automatic. It requires a continuous consumable flux, an electrode, and constant power supply. The shielded gas (inert or semi-inert gas) can also be used to protect the welded area from atmospheric contamination. But, the flux is enough to provide the necessary protection to the welded area. The flux - core arc welding was developed to overcome the drawbacks of the shielded metal arc welding. Advantages

Disadvantages

Electroslag weldingThe Electroslag welding process is used for thicker materials. The range of the material lies between 25mm and 300mm. The arc is extinguished in the case of electroslag welding. The flux is added to prevent the welded area from contamination. The flux is added to the wire until the molten slag reaches the tip of the electrode, which further extinguishes the arc. The electroslag process generally uses a DC as the power supply. The current range is around 600A. It is because welding on thicker materials requires high currents. Advantages

Disadvantages

Electrogas weldingElectrogas welding uses electric arc as the heat source. It requires an electrode connected with the external power supply to weld the work pieces. The primary difference between the electrogas and electroslag welding is that the arc is not extinguished. It means that the arc in the electrogas welding remains stuck between the electrode and the workpieces throughout the process. The electrogas welding is used in construction of storage tanks, ship-building, etc. Advantages

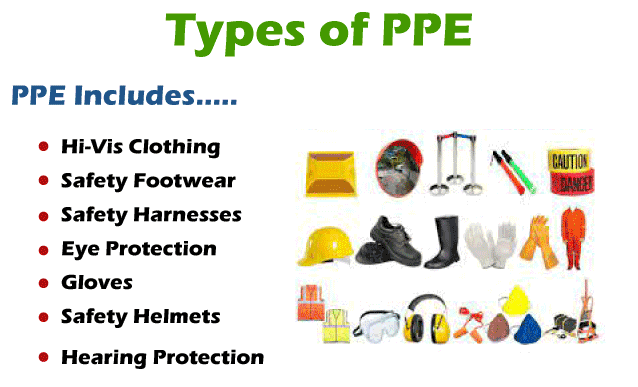

Safety IssuesWelding is not a simple process. It is necessary to take precautions when we perform any welding process. The use of proper safety measures, new technology, and protection helps to reduce the risk of injury causes due to welding. Most of the welding process uses open energy sources. Hence, the chances of being burnt by heat or fire increases. Let's discuss some safety measures, which are as follows:

Thus, using proper PPE (Personal Protective Equipment) is essential to protect from the harmful effects of welding. Ignoring these safe working practices can lead to serious injuries or even death. The types of PPE are shown below:

General Applications of weldingWelding plays an essential role ranging from the construction in the households to the industries. Most of the applications rely on electric arc welding for manufacturing and repair. The common applications of welding are as follows:

There are various welding methods used in the automobile industries, such as metal arc welding, laser beam welding, and tungsten arc welding. It is used to repair the cracks on the panels and other metal components. The welding has high productivity, quicker process, relevant cost, and produces a strong weld. Hence, it has become much popular in the automobile industry.

GTAW (Gas Tungsten Arc Welding) is the popular welding method used in the aircraft industry. GTAW can also perform welding on thicker metal parts. Welding is used in repair of engine parts, air handling ducts, and other components. But, alloy steel parts of the aircraft are not welded because they are specially manufactured to improve their mechanical properties.

The stairs in various households comprises of metal fences. It is generally made of metals, such as stainless steel. Welding is required to join the parts of the fence. The other uses of welding in a household are building gates, small appliances, etc.

The welding between the joint creates the adhesion between metal plates and other parts of the bridge. The parts of the bridges comprises of heavy metals. Hence, flux core arc welding is the common welding process used here.

The metals with different core properties are termed as dissimilar metals. The joining of two dissimilar materials requires a high heat level, such as gas tungsten arc welding, and shielded metal arc welding. Soldering vs. Brazing vs. WeldingLet's discuss the differences between the soldering, brazing, and welding processes that are used to fuse the two metal pieces.

Next TopicWorking Principle of a Transformer

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share