Advantages and Disadvantages of RobotsEveryone now has access to many tools thanks to technological improvements, which help everyone do their jobs faster and more efficiently. Therefore, designing robots to carry out tasks typically completed by people in large industries or organizations is a wise choice. In sectors that benefit from increased productivity, higher-quality output, and a safe working environment, it makes sense and is rational to employ robots for tedious and repetitive jobs. However, there are several advantages and disadvantages related to using robots in the industrial and service industries. Definition of Robot

Robots are automated devices that function much like humans. According to the Robotics Institute of America, robots are multi-tasking manipulators that may be designed to move objects like materials, parts, tools, and specialized equipment from one location to another. The Robot comes from the Greek term "force worker," According to popular belief, Karel Kapek was the first to coin the phrase "robot." The father of the Robot is said to be Insac Asimov. The most trying cut kind of automation is the Robot. Nowadays, robots are used in place of people to carry out various sophisticated tasks. Robotic devices are costly, but given their applications, their use across sectors is rising quickly. Three engineering disciplines must be united to create a robot machine; only then can the Robot be built. These three branches are as follows -

History of Robot

The Sperry gyroscope is credited as being used to create the first Robot. The construction of which began in 1913. However, in the 1932's London Radio broadcast, a wider audience first heard it. A U.S. corporation announced intentions to sell the Robot for the first time in close to 30 years, and gradually companies started shooting workers and replacing them with robots. The first occurrence happened in 1980 when a car manufacturer fired 200 workers and recruited 50 robots. In actuality, the robot workers accomplished a lot. Even the nuts and bolts of manufacturing machinery might be fastened and unfastened by a robot named Puma. Later, the medical industry saw the benefits of the Robot and developed a device called "Malang" that could locate cancerous tumours on a computer screen using artificial fingers. Robotics has advanced significantly in the modern era. Once known as "Ottoman" automated machines, robots successfully do their duties in nuclear reactors, fire departments, and scuba diving. Elements of RobotWe all know that a robot is a machine made of small elements and parts. The components of the Robot are as follows:

1. Actuator: It is a mechanism for transforming energy into mechanical energy. Its look is similar to a motor, which rotates and controls most machines. 2. Linkage or Manipulator: A manipulator is a device that enables a certain kind of movement for a robot or robot arm. This ties together a chain of adamant links. 3. Robot Controller: A controller, a computer that is used to operate the Robot, is utilized. The required software is placed into this controller to run the Robot and various processes. 4. Sensor: Robotic sensors are used to determine the location of the Robot and its surroundings. The Robot's sensors are built with the same concepts as human sensory systems. 5. Tooling: When a robot performs a task, specialized equipment is needed, such as electromagnets to lift or turn the workpiece, power drills, etc., to drill through the Robot. 6. User Interface: The Robot's activities using this interface are completed with human assistance. Types of Robots Based On Mechanisms

1. Stationary RobotsSuch robots are stationary and stay put. All of their work is done in one location, and they are made to function in that position with a fixed location and movement direction. For instance, stationary robots are those used for grasping, drilling, and welding tasks. 2. Wheeled RobotsRobots on wheels are robots with wheels that can travel across surfaces. Compared to legged robots, they are simpler to construct, program, and design. But they are only able to sprint on level ground. 3. Flying RobotsRobots with the ability to fly are known as flying robots. Small, unmanned robots are also available and capable of carrying out various duties. These machines are employed in search and rescue operations, and any natural catastrophe can quickly find people stuck throughout a wide land region. 4. Swarm RobotsA swarm robot is a collection of tiny robots operating as one big machine. The interactions that many robots have with one another and their surroundings are the foundation of their function. 5. Mobile spherical RobotsThe term "mobile spherical robot" refers to the spherical Robot. On the ground, they move by rolling or sliding. 6. Swimming RobotsA robot that swims in water is called a fish. Who resembles a fish in form and swimming technique? MIT University initially made swimming robot research available to the public in 1989. 7. Legged RobotsWhen the wheeled Robot started to dominate the robotics industry, experts toiled arduously to develop a superior replacement that would do away with some of its drawbacks. A wheeled robot, for instance, can only operate on level areas if it must perform tasks. The wheeled Robot cannot climb stairs, but if feet are put on it, it will climb them without a doubt. It is sufficient to start a machine by placing its feet on it, but given that it takes a human kid between one and two years to learn how to walk, can a robot be taught to walk by placing its feet on it? That's right, and it's also possible. Many of these robots have started to walk as well. Types of Robots Based On TasksRobots are generally divided into the following categories based on their use:

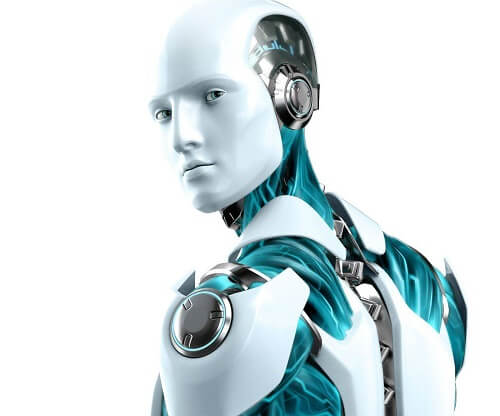

1. Research Robot The term "research robot" refers to a robot that does any study at a research facility. Going to the Research Center allows this Robot to do various duties. 2. Domestic Robot Robots used in the home, such as vacuum cleaners, sweepers, and gutter cleaners. 3. Industrial Robot Things utilized in the daily lives of humans are created nowadays all across the world. Several items are produced in industrial settings, including various food products, clothing, and automobiles. And in these fields, robots are also used. 4. Military Robot The military makes excellent use of robots. Security is another application for them. While it is challenging for humans to go there, they can do it easily. By visiting any location, they may successfully locate competitors. 5. Educational Robot An educational robot is a robot that is employed in the field of education. 6. Companion Robot The term "companion robots" refers to robots that live beside people, interact with them often, and provide for their needs. 7. Medical Robots Their utilization has taken on a significant role in medicine. Robots are being utilized one to one, and doctors now use artificial robotic hands to do procedures with the aid of robots. And because physicians may now save lives even when they are far away, medicine has revolutionized. 8. Humanoid Robot This Robot has a human-like form, and it has arms and a head as well. Research continues to be done on this Robot. Application of RobotThe major purpose of a robot over a human is that it never gets tired, works continuously without being hampered, is far more accurate than a person, and can never contradict itself. The set programming is how they always operate. Robots are being introduced into industrial sectors in nations like the U.S. and Japan at a pace of 35% annually to carry out commercial jobs, as per estimates. This is done for a variety of reasons.

Advantages of Robots

Disadvantages of Robots

Comparison Table for Advantages and Disadvantages of Robots

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share