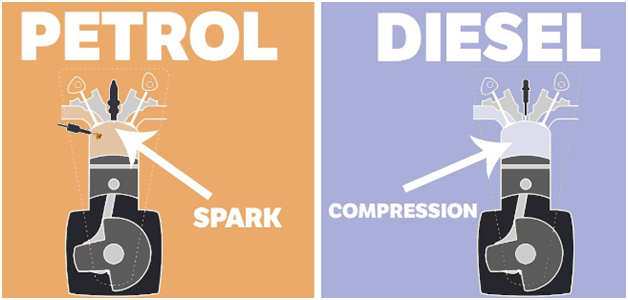

Difference between the Petrol engine and Diesel EnginePetrol engineThe petrol engine is also known as a SI engine, which stands for Spark Ignition engine. A petrol engine is an internal combustion engine that uses petrol and air to generate energy. Nicolas August Auto created the first gasoline engine in 1876. The autocycle principle governs the operation of a gasoline engine. Spark plugs are employed in gasoline engines because they are required to ignite the mixture of gasoline and air inside the cylinder chamber. The operation of a gasoline engine and a diesel engine is nearly the same. Suction stroke The piston of the engine swings from top to bottom in this stroke while the inlet valve is opened, and the piston draws a mixture of gasoline and air into the cylinder. The input valve remains open, and the exhaust valve remains closed during suction stroke. After the suction stroke is done, the compression stroke begins. Compression stroke After the suction stroke, the piston swings from bottom to top, compressing the air-fuel mixer while the intake and exhaust valves stay closed. The temperature and pressure of the air-fuel develop dramatically during the compressor stroke, after which the spark is blasted inside the cylinder with the help of a spark plug, which starts the power stroke. Power stroke During the power stroke, the piston moves from top to bottom, and the crankshaft rotates because it is attached to it. As a result, the engine gains power. That is why it is also known as a power stroke. Exhaust stroke The piston rises higher during this stroke, from TDC to BDC. It opens the outlet valve, allowing waste gases to exit the cylinder chamber. After finishing the exhaust stroke, the piston drops again, and the cycle starts over with the initial stroke. Engine typesGasoline engines are divided into numerous variations based on application, fuel management mechanism, ignition, piston-cylinder or rotor configuration, a number of strokes per cycle, cooling system, and valve type and placement. This section is discussed in the context of two main engine types: piston-cylinder engine and a rotary engine. In a piston-cylinder engine, the pressure created by the combustion of oil exerts a force on the head of the piston, causing it to reciprocate along the length of the cylinder. This force pushes the piston away from the cylinder head and works. Wankel engines do not have conventional cylinders with reciprocating pistons. Instead, gas pressure acts on the surface of the rotor, causing it to rotate and produce work.

Engines with a piston and a cylinderThe majority of gasoline engines are of the reciprocating piston-and-cylinder variety. The image depicts the basic components of a piston-and-cylinder engine. Almost all engines of this sort operate on either a four-stroke or a two-stroke cycle.

A term that first appeared in the late 1800s, the four-stroke cycle was the primary technology for recovering energy from the combustion process. The diagram shows a 4-stroke cycle. In the intake stroke, the piston first descends when the intake valve opens. An ignitable mixture of gasoline vapor and air is drawn into the cylinder by a vacuum. With both valves closed, the mixture is compressed as the piston rises on the compression stroke. Near the end of the stroke, an electrical spark ignites the charge. The power stroke continues, both valves remain closed, and gas pressure from the expansion of the combustion gases pushes against the piston crown. The rising piston pushes waste products of combustion through the open exhaust valve during the exhaust stroke. Then the cycle continues. So each cycle needs 4 piston strokes (intake, compression, power, exhaust) and 2 revolutions of the crankshaft. The downside of a 4-stroke cycle is that it does half the power stroke of a 2-stroke cycle, producing half the power from a given size engine at a given operating speed. The 4-stroke cycle, on the other hand, allows for more aggressive exhaust cleaning (scavenging) and cylinder recharging, limiting the loss of new charge to the exhaust.

The compression and power strokes of the four-stroke cycle are carried out in the original two-stroke cycle (as it was established in 1878) without the inlet and exhaust strokes, needing just one crankshaft rotation to complete the cycle. In the two-stroke cycle engine of the so-called uniflow type, the new fuel mixture is pumped into the cylinder through circumferential ports by a rotating blower. The poppet valves in the cylinder head that the exhaust gases travel through are controlled by a cam-follower system. When the cylinder pressure has significantly decreased at the conclusion of the power stroke, the valves are timed to start opening. After the exhaust opening reduces the cylinder pressure to the intake pressure generated by the blower, the inlet apertures in the cylinder wall begin to uncover. After the rising piston has covered the inlet ports on the compression stroke, the exhaust valves are left open for a short period of crank rotation, enabling the flow to continue and fully scavenge the cylinder. Similar to a four-stroke engine, the compression and power strokes are used. Asymmetrical piston enginesUniflow scavenging is also provided by the opposed-piston engine. Two pistons are rotating in opposition inside the same cylinder in this engine (part A of the illustration). Two sets of ports are positioned so that one set is controlled by one piston and the other set is controlled by the second piston, with both sets extending completely around the cylinder bore. At the top of the engine is another crankshaft, to which the higher pistons are linked. Gears connect the two shafts. Two key benefits of the opposed-piston design are the elimination of the poppet valves required in other uniflow-scavenged two-stroke-cycle engines and the superb balance provided by the reciprocating masses moving in opposing directions. Wankel (rotary) enginesThe construction of the German-developed rotary-piston internal combustion engine differs significantly from that of traditional reciprocating piston engines. Felix Wankel, an expert in the construction of sealing mechanisms, came up with the idea for this engine, which a German company produced and tested trial units of starting in 1956. The Wankel engine uses an equilateral triangle circling rotor instead of pistons that travel up and down in cylinders. The three apexes of the rotor maintain constant sliding contact with the convex inner surface of the casing while it rotates inside a sealed chamber. Between its sides and the curved wall of the casing, the rotor's curve-sided design creates three crescent-shaped chambers. The chamber volumes change depending on the rotor position. When the side of the rotor producing the chamber is parallel with the casing's minor diameter, the volume in each chamber is at its maximum; when it is parallel with the casing's major diameter, the volume is at its lowest. The form of the combustion chambers and the engine's compression ratio are controlled by shallow pockets recessed in the rotor's side. Advantages of petrol car1. It is cheaper Typically, a petrol vehicle from any manufacturer costs between 60 and 1.5 times less than a diesel vehicle of the same kind. A gasoline-powered automobile depreciates less than a diesel-powered one. Depreciation refers to the annual decrease in the automobile's original worth, which is taken into consideration when a car is sold after a few years of use. 2. Simple to switch to CNG If CNG is readily accessible in your city and you wish to use it to replace your gasoline vehicle for whatever reason. In this case, an automobile with a gasoline engine will be less expensive for you than one with a diesel engine. Because installing CNG in a diesel car costs money because modifications to the engine are required, whereas CNG kits simply fit in petrol vehicles. 3. Cost-effective service Because a diesel engine is built to be able to resist high temperatures, which makes its engine parts more expensive, repairing a diesel car will cost more money than servicing a fuel vehicle. However, this is not true with gasoline-powered engines. This explains why maintaining gasoline-powered automobiles is also less expensive. 4. Pollution is less contagious Your first option should be a petrol engine vehicle if you are an environmentally concerned person who also cares about society and wants the next generation to be able to breathe clean air like you because it significantly lessens air pollution than diesel Engines. Since the BS6 engine was approved by the Indian government, pollution from gasoline engines has decreased dramatically. While the desire in building cars with diesel engines has decreased recently. 5. Pollution is less contagious How much noise does it make? is the first thought that crosses everyone's mind when they consider a diesel engine. By the way, the business now utilises insulation extensively, and diesel engines are now much more sophisticated than they were in the past. But compared to a gasoline engine, it will always be louder. 6. It responds instantly Compared to diesel cars, gasoline automobiles have a significantly greater throttle response. This explains why driving gasoline-powered cars is more enjoyable than driving diesel-powered cars, which are a little slower. Disadvantages of petrol car1. Life spans are brief The life of the engine in a diesel or gasoline car is shorter. 2. Less expensive to resell The lifespan of a gasoline engine is substantially shorter than a diesel engine's, which accounts for the lower resale value of a gasoline car. 3. Gas prices are high Long-distance driving in gasoline cars is still expensive in today's globe since gasoline is still more expensive than diesel. 4. Costly maintenance will be required Petrol automobiles need more routine upkeep and maintenance than diesel ones. In comparison to diesel cars, it tends to degrade if service is neglected on occasion. 5. Attention must be paid to the quality of gasoline Petrol has several contaminants as well, so if you do not get it from a reputable source, it may end up costing you much over time. Using poor fuel can seriously harm your car's fuel pump and fuel injection system. Diesel EngineAn internal combustion engine that has diesel fuel pumped into the cylinders and heated to a temperature sufficient to ignite it is called a diesel engine. It converts the chemical energy contained in fuel into mechanical energy to power seagoing vessels, large tractors, freight trains and locomotives. Some generator sets and a few cars are also diesel powered. Diesel engine burningPiston-cylinder diesel engines operate with intermittent combustion. It can be 2-stroke or 4-stroke (see diagram), but unlike spark-ignited spark-ignited engines, diesel engines introduce air into the combustion chamber only during the intake stroke. Diesel engines generally have compression ratios between 14 and 14. Major diesel engine typesDiesel engines can be divided into three basic classes based on power output, i.e., Small, Medium, and Large. 1. Small engines Small engines have less than 188 kilowatts or 252 horsepower. The most common type of diesel engine is this. These engines are used for mechanical propulsion, small stationary generators (such as those found on pleasure boats), some agricultural and construction applications, light vehicles, passenger cars, and light trucks. It usually has a 4-cylinder or 6-cylinder in-line engine with direct injection. Many have aftercoolers and are turbocharged. 2. Medium engines The power range for the midsize engine is 252 to 1,006 horsepower or 188 to 750 kilowatts. Heavy vehicles use these engines most often. These are typically 6-cylinder in-line engines with direct injection and aftercooling. Some V-8 and V-12 engines also fall into this size category. 3. Large engines The large diesel engine has a rated output of over 750 kilowatts. These unusual engines are used to generate electricity and power ships, locomotives and mechanical drives. They are typically aftercooling, direct injection and turbocharged systems. Run as low as 500 rpm when reliability and durability are important. 2 and 4-stroke enginesAs mentioned earlier, diesel engines operate in 2-stroke or 4-stroke mode. Intake and exhaust valves and fuel injectors are all located in the cylinder head of a standard 4-stroke engine (see diagram). A dual-valve configuration consisting of two intake valves and two exhaust valves is often used. Development of diesel enginesThe German engineer Rudolf Diesel got the idea for the engine that bears his name while looking for a way to improve the efficiency of the Otto engine. The first four-stroke engine built by a 19th-century German engineer, Nicholas Otto. Diesel realised that the electric ignition process of a gasoline engine could be eliminated if compression could heat the air to a temperature higher than the auto-start temperature of a given fuel during the compression stroke of the piston-cylinder unit. Diesel proposed such a cycle in his 1892 and 1893 patents. At first, either powdered coal or liquid oil was offered as fuel. As a widely available fuel, diesel produced pulverised coal, which was a by-product of Saari coal mines. Compressed air had to be used to feed coal dust into the engine cylinder; However, controlling the rate of carbon injection proved problematic, and when the test engine was destroyed in an explosion, the diesel switched to liquid oil. He continued to feed the engine with compressed air. Brewer Adolphus Busch, who saw it at the Munich Exposition and obtained a license from Diesel to build and sell the engine in the United States and Canada, installed the first commercial engine built on Diesel patents in St. Louis, Mo. The engine was the forerunner of the Busch-Sulzer engine that powered several US Navy submarines during World War I of the New London Ship and engine company in Groton, Conn., another diesel engine used for the same purpose. During the first world war, the diesel engine became the main power plant for submarines. It was not only fueled and efficient but reliable during the war. Diesel oil, which is less volatile than gasoline, was stored and handled more carefully. Many of the men who worked on diesel looked for work after the war. Manufacturers first adapted diesel engines to the peacetime economy. One adaptation was the creation of the so-called semi-diesel, which used a lower compression two-stroke cycle and a hot bulb or tube to ignite the fuel charge. These changes resulted in a cheaper engine to produce and maintain. Advantages of diesel vehicle1. Excessive driving Diesel engines use a compression-ignition technique and are more efficient than gasoline engines. The influence of this phenomenon on car mileage is well recognised, which is why diesel-powered vehicles have high mileage. 2. The diesel engine is long-lasting A diesel engine requires high temperatures to function, which is why the materials used to construct diesel engines are of high grade. Therefore, diesel engines can tolerate harsh environments. This is also a major reason why commercial diesel-powered vehicles predominate. The durability of its engine can be deduced from the fact that, even today, Mercedes Benz diesel cars have traversed a distance of more than 14 lakh kilometres. 3. The resale value is excellent The resale value of a vehicle is the price it would get if it were sold after a few years of use. If you take proper care of your vehicle, you will find that after a few years, people will still want to buy your diesel vehicle for a good price. If all of this is conceivable, the only explanation is the engine's quality and maintenance. 4. Capable of running on a variety of fuels This may seem unusual, but it is true that a car powered by a diesel engine may run on more than one fuel. You can power this vehicle by producing biodiesel at home or purchasing it at a market. However, this is not conceivable in a gasoline car; at best, ethanol-containing gasoline can be used in a gasoline-powered vehicle. 5. Simple to maintain The diesel engine has substantially greater steadiness. As a result, there are relatively few issues that will arise during the maintenance of these automobiles. If these vehicles are involved in an accident for whatever reason, the risk of fire is substantially lower than that of gasoline automobiles. 6. There are many possibilities When you leave the house to get vehicle information, you will see that diesel automobiles have many more possibilities than gasoline vehicles. In addition, some model or another car will undoubtedly be included in your budget. 7. Comfortable driving experience Diesel vehicles are highly powerful, and they have a lot of torque, which improves your driving experience. Diesel car disadvantages1. Expensive Diesel vehicles are unquestionably more expensive than gasoline ones. The high cost of these cars is due to the materials used in the engines, which are exceedingly expensive and must perform at high temperatures. If you frequently travel by vehicle and your vehicle is largely going to be on the road, you should try to acquire a diesel vehicle. It will certainly fill your pocket at first, but over time, you will earn more money from fuel and vehicle will be able to recover via quality. 2. Servicing will be costly Yes, you read that correctly; diesel vehicle repairs are somewhat pricey due to the high cost of the components used. As a result, I'd like to make the idea that you get your vehicle maintained and checked on a regular basis because if it sits, your pockets will undoubtedly become loose. 3. Diesel engines are sluggish Yes, diesel vehicles are slightly slower than gasoline vehicles; you will not achieve the same speed. Before purchasing a vehicle, you must decide whether you desire speed or a vehicle that will last you a long time. 4. The issues will worsen in the cold If you reside in an area where the weather is frequently below freezing, a diesel car may cause trouble. If you tow the vehicle outside the house in an open area, the problem will worsen. Because starting diesel automobiles in cold weather is difficult, people who live in such areas prefer petrol vehicles. Difference between Petrol Engine and Diesel Engine

Next TopicDifference between

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share