Difference between production and manufacturing

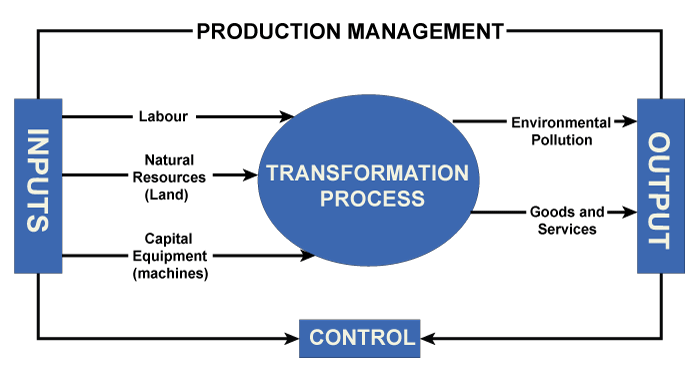

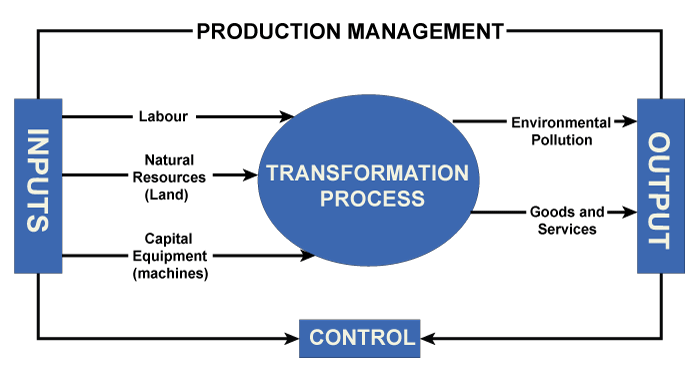

We all use products and are surrounded by goods in our everyday life. From tangible to intangible, from hardware to software, furniture to electronics, and vehicle to toys, all go through a production process to get finished goods. Generally, there are two words, "Production" & "Manufacturing," related to goods and considered synonyms & can be used as a replacement for each other. People can use them interchangeably, but entirely they are different. They both are different terms that need to understand:- ProductionProduction refers to making manufactured goods and products from raw materials, or we can take input to produce output that is fit for consumption. Production is a step-by-step method that starts from:

Production processThe production process works step by step, where one step depends on the other, and to understand this, we can make a flow chart. Because the production process can be carried out in multiple ways depending on the industry's need and production line, some basic stages still vary from industry to industry. Step 1: Planning It is the basic step of all the work needed to define the purpose and method of achieving the production goals. It creates a rough chart of how the products will be produced. Step 2: Routing This step provides a route to the production process in which raw materials are procured, processed, finished, quality checked, and distributed. This crucial stage includes the decision on the quality and quantity of goods and services in the production process. Step 3: Scheduling Here comes the timing of the production process, what time should each production stage involve? And the timing of workers on a particular workflow. Step 4: Dispatching At this stage, the actual production starts, involving the production of items, monitoring the workflows according to plan, maintaining records, recording machine work, machine idling time, etc. Step 5: Follow-up At this last stage, all the performed actions are measured to compare with the expected productions. It is mandatory to follow up the stages to detect the problem and find solutions to remove them following smooth functioning of the process. Factors of production are capital, labor, technology, and land.

Types of productionTypes of production depend on the company's product and organization needs, and these are: 1. Batch production: It is probably the same as mass production, but the difference is that product is produced in batches based on product color, size, form, etc. Example of batch production: craft brewing and banking 2. Job production: It includes the production of a limited quantity of products (specific to customer preferences). Production takes place at a small scale where a single item is fully prepared or produced before taking up other jobs. Examples of job production: shipbuilding industry and custom furniture production 3. Mass production: All workers work continuously to produce one item simultaneously. Every employee focuses on producing the same product with the same form and size and utilizing all resources to produce the same range of products. Multiple tasks are carried out simultaneously with the same efficiency to get effective and fast results. For example, the production of chips is on a huge level where all employees focus on making chips. Employees work in different sections like washing potatoes, peeling potatoes, chopping them, frying them, adding flavors to them, packaging them, etc. Mass production examples: electronic industry and automobile industry 4. Customized production: This production is based on the customer need, where goods and services are produced on order and divided into two categories: craft production and mass customized production. Examples of customized products are the garment and automobile industries (customization). 5. Service production: In this rendering, services are involved through an automated process like customer technical support. Best service production is delivery service where customers can order goods and services from their homes and receive them at their doorstep due to the sheer amount and scope of delivery services available. Examples of service production: law industry and consulting industry Jobs related to the production process

ManufacturingManufacturing refers to the process of producing finished goods from raw materials. Method of producing final goods from scratch via using machines or other tools. It is a multi-step process in which finished goods are produced using machinery and raw material (raw materials are cut according to need, and a new finished product is produced). Companies manufacture products for sale with the help of machines, human resources, raw materials, and chemical & biological processes.

"Manufacturing is the step-by-step making of finished goods involving machinery, human resources, raw material and another requirement for the product from a basic small industry to technologically advanced ones." The finished products can be further used to manufacture complex products like ships, aircraft, automobiles, household substances, etc. Then these final goods are sold by manufacturers to wholesalers. Manufacturing is considered a large-scale production of goods sold to customers (retailer purchases from wholesalers and sells them to consumers) to make a profit. The modern concept of manufacturing includes the production and integration of product components. It is of five types:

Some of the different manufacturing methods:

Mostly all businesses manufacture goods for sale and use of customers, and before that, they perform these functions:

Therefore production and manufacturing are two different terms with different functioning but with the main aim of producing goods to sell and used by customers and growing the business.

Next TopicDifference between

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share