Solenoid

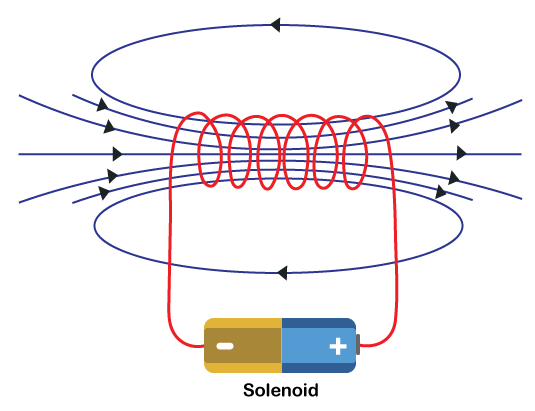

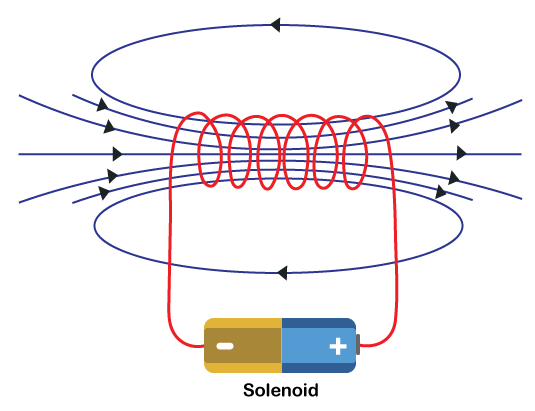

A solenoid is a type of electromechanical device used to convert electrical energy into mechanical energy. It generates a magnetic field when an electric current is passed through the circuit. Solenoids are often known as electromagnets.

The magnetic field generated from solenoids can also be used. The circuit comprises a coil (arranged in the form of the helix), electric circuitry (for an electric connection), and a metal core.

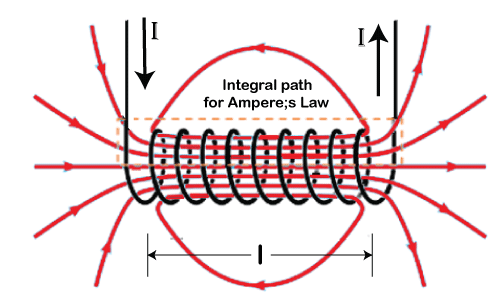

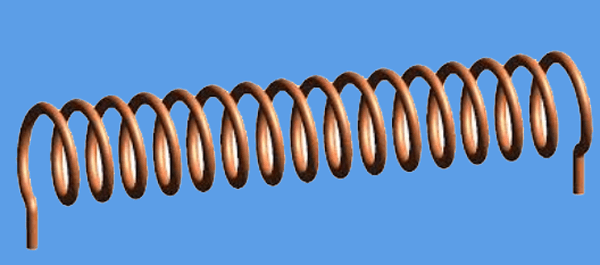

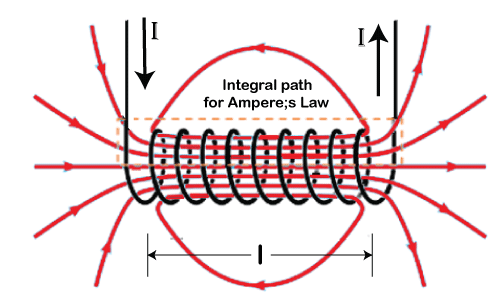

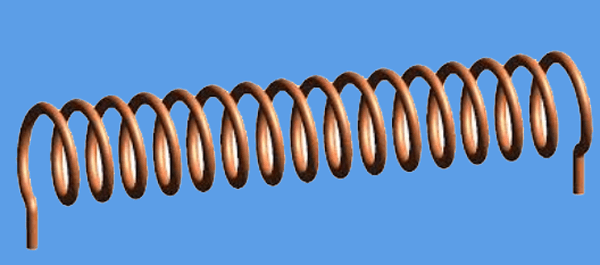

The coil in the form of a helix is shown below:

We can use any metalcore, for example, an iron nail and any shape of an iron. The applications of the solenoid are valves, antenna, inductors, etc.

Here, we will learn about the solenoid principle, types of the solenoid, working of solenoids, how solenoids are created, etc.

Principle of Solenoid

The principle of the solenoid is based on electromagnetism. A solenoid coil consists of a metal core with copper wire windings, which acts as an electrical element.

Such winding provides a path for the current to flow. The magnetic field is generated when an electric current flows through the coil.

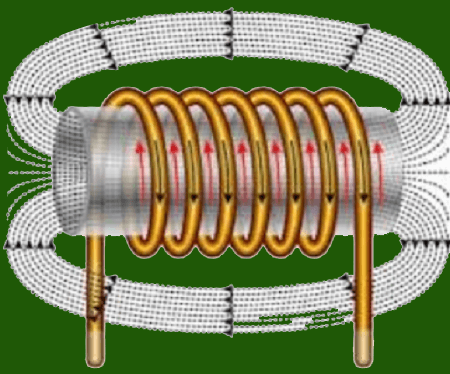

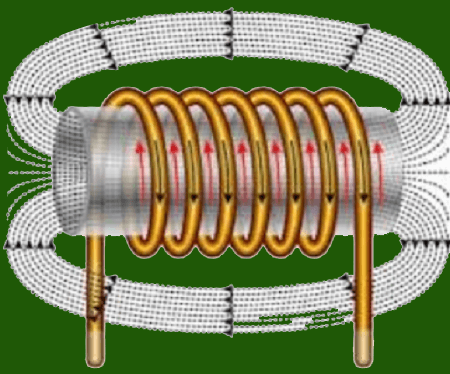

The core of the solenoid can be air but would have small induction. Whenever we use the metal core, the magnetic flux lines focus on the core. It further increases the induction of the coil. Such a concept is also known as electromagnetic induction.

The uniform magnetic field generated by the solenoid is similar to the bar magnet's magnetic field.

Most of the flux is concentrated on the core of the coil. Some of the flux can be seen at the end of the coil, while some appear outside the coil.

Working of Solenoid

A solenoid consists of a core that is made up of metal. Metal increases the magnetic flux density of the solenoid. The solenoid is a coil or windings of the magnet wire or copper wire on the metalcore.

The electric current passes through the copper wire mounted on the core. When an electric current flows through the solenoid, the magnetic field is generated. It causes the solenoid to behave as an electromagnet.

Can we increase the strength of the solenoid?

Yes,

We can increase the solenoid's strength by either increasing the number of turns on the metal core or the flow of current through the coil. The higher number of turns increases the magnetic field strength of the solenoid.

Advantages of Solenoid

Let's discuss some advantages of using the solenoid:

- The magnetic property of solenoid can be controlled by allowing or blocking the electric current passing through it.

- It has an extensive use in automated applications.

- Light in weight.

- Low price.

- Simple construction.

- Engines made with the help of solenoids can be used as an alternative to fossil fuels.

- No pollution

- Solenoid engines have better efficiency compared to other engines.

- Low power consumption

- Easy to fit in big engines or devices

- Compatible with both DC and AC voltage

- The parts of a solenoid can be easily replaced and are generally cheap.

How are solenoids created?

The solenoids can be created in different ways. Some solenoids can be created for an experiment at home. But, big solenoids are prepared at the industrial level. Here, we will discuss two methods to create a solenoid that is easily created at home.

1. Solenoid using Iron nail

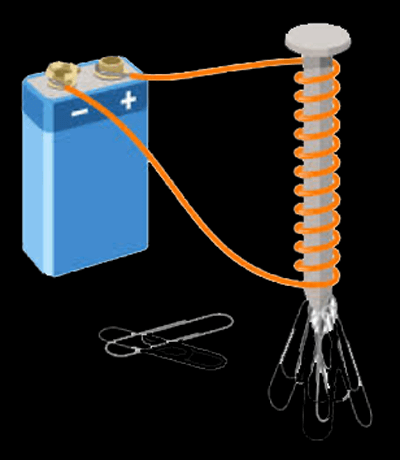

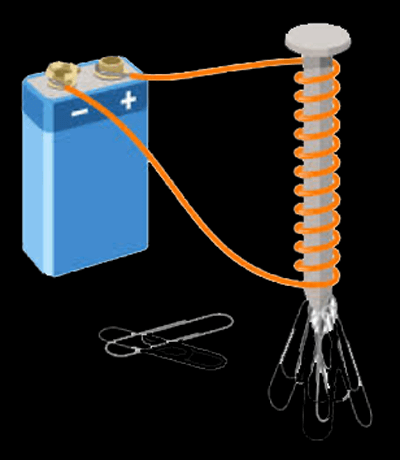

Required Components: Copper wire, any iron core (for example, iron nail), and a 9V battery. For a small nail, we can also take a remote cell.

Connection Setup: Take an iron nail and wrap the copper wire on it in the form of a helix. Connect the two terminals of the wire to the two terminals of the battery. The minimum number of turns can be 20. We can increase the turns depending on the length and required strength. For better performance, we can smooth the edges of the wire using sandpaper or a knife.

As soon the connection is complete, after a few seconds, the circuit will work as a magnet.

Note: Battery gets heated soon. So, do not operate it for a long time.

Working: When we connect the terminals of the battery to the two ends of the copper wire mounted on the iron nail, the electric current flows through the wire. It generates the magnetic field, and the coil starts working as an electromagnet. Bring any iron object near the solenoid; it will attract to it.

When the power is switched OFF, the electromagnetic field starts collapsing, and the energy stored comes back to its rest position.

The setup will appear as the image shown below:

Note: Always use coating wire to create a solenoid. We can also use magnet wire. Magnet wire is similar to copper wire but with a thin coating.

2. Solenoid using plastic pipe or straw

We can also make a solenoid using a plastic pipe or straw as a core material. As discussed, these materials have very little induction as compared to solenoids with iron core.

We can wrap the cello tape on it with a sticky side on the exposed area in the case of straw. It will be easy for us to wrap the wire on it.

Let's discuss the procedure.

Required Components: Copper wire or magnet wire, plastic pipe or straw wrapped with tape, and a 9V battery.

Connection Setup: Take a plastic pipe or straw and wrap the copper wire on it in the form of a helix. Connect the two terminals of the wire to the two terminals of the battery. For better performance, we can smooth the edges of the wire using sandpaper or a knife. As soon as the connection is complete, the circuit will work as a magnet after a few seconds.

The working of such solenoids is similar to the discussed one except with reduced induction.

Working: When we connect the battery terminals to the two ends of the copper wire mounted on the plastic pipe, the electric current flows through the wire. It generates the magnetic field, and the coil starts working as an electromagnet. Bring any iron object near the solenoid; it will attract to it.

When the power is switched OFF, the electromagnetic field starts collapsing, and the energy stored comes back to its rest position.

Note: If we do not have a 9V battery, we can place two or three battery cells in series for the connection.

The above two solenoids can be created easily at home.

We have discussed the procedure to create the solenoid and how its strength can be increased. So, let's derive the formula that will help us clearly understand the number of turns and other parameters of a solenoid.

Derivation

Let's first discuss Ampere's law. According to Ampere's law:

The magnetic field produced by the current passing through the circuit is proportional to the electric current multiplied by free space's permeability.

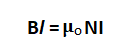

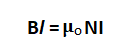

The solenoid, according to the above law, gives us:

Where,

B is called the magnetic flux density.

N is the number of turns.

I is the current passing through the windings.

L is the length of the solenoid.

It is the permeability of free space.

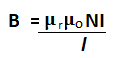

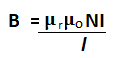

Let's calculate the value of magnetic flux density from the above formula:

The above value is considered in the case of the solenoid in free space. It means that relative permeability is equal to the permeability of free space.

If we insert a solenoid in a material that has relative permeability, we get:

Now magnetic flux density has another parameter called relative permeability.

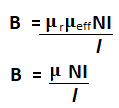

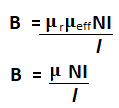

Sometimes, a solenoid is not completely immersed in the material having high permeability. In such a case, the apparent effect of relative permeability is seen on the solenoid. It means that a partial part of the solenoid is in free space, while the other part in the material with high permeability.

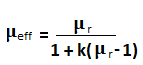

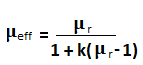

As discussed above, iron or metalcore increases the magnetic flux density of the solenoid. It further causes a change in the effective permeability in the magnetic path of the solenoid. It can be calculated as:

The relationship between relative and effective permeability can be written as:

Where,

K is the demagnetization factor.

Inductance of a Solenoid

As discussed above, magnetic flux density (B) can be written as:

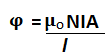

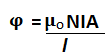

The total magnetic flux through the coil of the solenoid can be represented as:

Where,

B is called the magnetic flux density.

N is the number of turns.

I is the current passing through the windings.

L is the length of the solenoid.

It is the permeability of free space.

A is the cross-sectional area.

Total magnetic flux is also defined as the product of magnetic flux density and cross-sectional area.

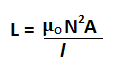

Inductance in the solenoid can be defined as the tendency of a conductor (electric conductor) to oppose the change in electric current passing through the circuit.

The inductance can be represented as:

Putting the value of total magnetic flux in the above equation, we get a solenoid inductance.

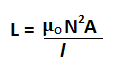

The inductance of a solenoid can be represented as:

Where,

L is the Inductance of the solenoid.

N is the number of turns.

l is the length of the solenoid.

It is the permeability of free space.

A is the cross-sectional area.

Irregular Solenoids

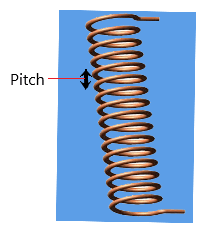

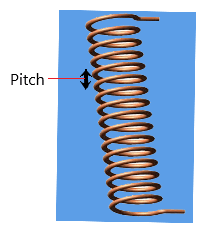

A pitch or the radius of a loop of a winding determines the category of the solenoid. Pitch is defined as a gap between the windings, as shown below:

A solenoid with varying pitch or radius of a loop is called an irregular solenoid. The applications of irregular solenoids include non-cylindrical solenoids, etc.

Types of Solenoid

Let's discuss some of the common types of solenoids.

Linear Solenoid

Linear Solenoid is an electromechanical device that produces linear motion. The core of the linear solenoid is movable metalcore. We can easily apply to push or pulling force on any mechanical device due to its movable core. These solenoids are commonly used as starting devices.

The applications of linear solenoids include bike motor starters, automation, starters, motors of car, etc.

Electromechanical Solenoid

The electromechanical solenoids are defined as the solenoids that consist of a movable armature core. The material of the core can be iron or steel. The shape of the coil is such that the armature can easily move inside and out from the coil center.

The common applications of solenoids include fuel injectors, pinball machines, etc.

We can easily make a solenoid such type of solenoid at home. For this, we need an iron nail, magnet wire or copper wire, and a hollow plastic pipe. Wrap the copper wire on the hollow plastic pipe. Put the iron nail very close to the pipe. Connect the two corners of the wire to the two terminals of the battery. As soon as the connection is complete, the device will behave as an electromagnet, and the iron nail will move inside the pipe. We can also use a hollow metal pipe.

Rotary Solenoids

Rotary Solenoids are based on the mechanism of ratchets. Ratchets are the device that supports continuous rotary or linear motion in a single direction. It does not support these motions in the opposite direction.

Rotary solenoids have a wide range of applications. The control of these motors is quite easy. The structure of these motors is similar to other motors. It consists of a large flat disk, on the center of which an armature core is mounted. The grooves are present under the disk with a size similar to the size of slots. The ball bearings in the solenoid make the motion easy.

When the power is switched off, the solenoid's spring pushes the core disk to move into its original position.

Automobile Starter Solenoid

These starter solenoids are a part of the automobile system. The functioning of the automobile starter solenoids requires high and small current for its operation.

It takes a small current from the ignition system and a high current large current from the car's battery.

The starter solenoids are generally visible on the outer of the starter of the car. Sometimes, it produces a cracking sound when unable to extract insufficient power from the battery. It may damage the battery.

AC Laminated Solenoid

The core of the AC laminated solenoid is a laminated metal with the windings of the copper wire. The lamination of the metal core helps in reducing the stray current. The stray current is the current that flows in the unintended path other than the designated path.

The AC Laminated Solenoids has the advantage of delivering a high amount of force in a single stroke. As compared to DC Laminated solenoids, it can deliver more strokes.

These types of solenoids are used in an application that requires sudden action, for example, vehicles, printers, medical equipment, etc.

DC C-Frame Solenoid

C or D describes the shape of the frame in which the coil is covered. The name is DC, but also suitable for AC applications.

The DC-C Frame Solenoids have a C-shape frame. The stroke's capability of these solenoids is much controllable. Such solenoids are used in a variety of applications, such as circuit breakers, coin counters, etc.

DC-D Frame Solenoid

DC-D Frame Solenoid has two frames that are used to cover the coil of such solenoids. It also has controlled stroke capability. Such solenoids are used in both medical and conventional applications, such as ATM Machines.

Solenoid Valves

A valve is defined as a device, which controls the flow of fluid by controlling various passageways. It is the most common type of device.

Solenoid valves are the valves that can be operated electromechanically. The valves are categorized based on the magnetic field's strength, the amount of required electric current, and the type of fluid. It is used to perform different tasks, such as mixing or distribution of fluids, etc.

Solenoid valves can be a 2-way, 3-way, or a 4-way. A 2-way valve has two ports, while a 3-way valve has three ports. Similarly, a 4-way valve has four ports.

Let's discuss some categories of solenoid valves.

Direct-Acting valves

The operation of the valve depends on the magnetic energy produced from the solenoid. It also prevents the device from excess pressure.

Hydraulic solenoid valve

These valves control the flow of hydraulic liquids. Such solenoids are used by the hydraulic machinery to control the actuators, oils, or rams.

Pneumatic solenoid valve

The Pneumatic solenoid valve requires a small signal for the device operation.

Pilot-Operated Valves

Pilot-Operate valves use the technique of different pressure, which can be applied over the ports of a valve to open or close it.

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now