Types of MagnetsMagnets are common in normal life, and almost everyone knows about them. In particular, magnets are known as those materials that have the property of attracting and repelling certain metal materials, such as iron and nickel. However, this is not always the case. Magnets can sometimes lose their magnetic property and thus cannot attract or repel similar materials. It is all based on the type of magnet we are using. Therefore, it is essential to learn about the types of magnets. In this article, we are discussing different types of magnets and their basic properties, characteristics, and uses. Before discussing the different magnet types, let's first understand the definition of magnet: What is Magnet?A magnet refers to an object capable of generating a magnetic field, or a force-field that attracts 'unlike poles' and repels 'like poles'. Magnets use a phenomenon known as magnetism, which helps them generate a force that further acts as a magnetic field (the particular magnet area). This eventually forms two poles, which align to the south and north. The generated field enters the magnet at the South Pole and exits again at the North Pole. This magnets' ability is found naturally in some materials (e.g., Loststone), or it can be formed by combining with specific elements (e.g., samarium cobalt). In general, magnets are solids that either attract or repel certain materials, such as iron, nickel, and even steel. The following are some characteristics of magnet:

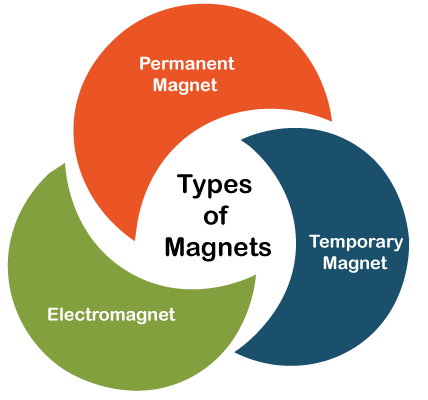

Properties of MagnetThe basic properties of magnets are described below: Attractive Property: According to this property, the magnetic force at the magnets' poles' ends is the highest. Directive Property: This property is responsible for understanding the concept of north and south poles. This means that this property usually helps identify whether the magnet's pole is the North Pole or the South Pole. Law of Magnetic Poles: According to this, like poles of different magnets repel each other, unlike poles attract each other. Pair Property: This property defines that whenever a magnet is cut or broken, one North Pole will appear on one of the broken faces and one South Pole on the other as if each piece has its own North and South Pole. Sure test of Magnetization: The magnetization surety test is mainly performed to check whether the iron rod has been magnetized. This is done by examining the attraction or repulsion properties between the rod and the magnet. Types of MagnetsBecause not all magnets work the same and are made of different elements, they can be classified into different types. Based on their structure and source of magnetism, magnets are mainly classified into the following three types:

Let us understand each type: Permanent MagnetPermanent magnets are the type of magnets that are most commonly and widely used in normal life. Once magnetized, these magnets do not easily lose their magnetism property. Permanent magnets are known to retain their magnetic property unless they are necessarily demagnetized using any of the following methods:

Permanent magnets are mostly used in refrigerators, jewelry, bags, magnetic walls, etc. These magnets are usually made of nickel, steel or neodymium. Such materials tend to have a property that allows them to be easily magnetized. Therefore, whenever these materials are placed in a magnetic field at some specific level, they begin to act like magnets and remain permanently magnetized. Permanent magnets may be naturally occurring elements (such as rare-earth) or chemical compounds. Typically, the permanent magnets are further divided into two categories. The first category includes metal alloy magnets, such as aluminum nickel cobalt magnets, samarium cobalt magnets and neodymium iron boron magnets. Besides, the second category includes ferrite or Ceramic permanent magnets. They are:

Temporary MagnetTemporary magnets are defined as materials magnets, such that when the material is placed in a magnetic field, it acts as a permanent magnet. Temporary magnets lose their magnetism after the magnetic field is removed. Unlike permanent magnets, temporary magnets do not retain their magnetic property. This is why they are called temporary magnets. Some irons, iron alloys, iron nails and paper clips act as a temporary magnet in the presence of a magnetic field. ElectromagnetsElectromagnets are the magnets created by winding or wrapping a wire in several loops around a metal core composed of iron. When this arrangement (known as a solenoid) is placed by the electric field, and an electric current is passed through it, the wire's energized coil generates the magnetic field. This eventually forces the material to act as a magnet. The strength of magnetism can be controlled by adjusting or altering the electric current's strength and direction. Besides, the field inside the prepared coil is the highest, and the strength of the field is directly proportional to the number of wire loops and the carried current. When the electric current is stopped, the magnetic field disappears, and so the metal's magnetism property. The material used in the center of the electromagnet arrangement may also influence the overall electromagnet's power. As a result, electromagnets also are not permanently magnetic. Electromagnets are mainly used for applications that require strength. Some examples of electromagnets are motor engines, railroad tracks, cranes, and MRI machines. They are also preferred in computer hardware and television components. Uses of MagnetsFew most common uses of magnets are listed below:

Next TopicCPR-Definition

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share