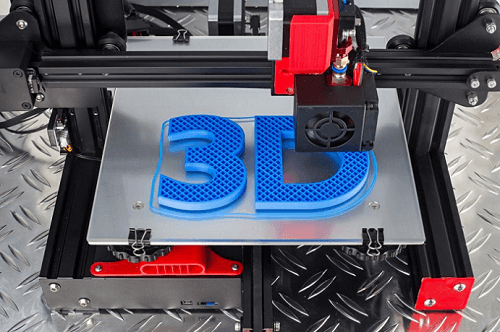

Advantages and Disadvantages of 3D PrintingNo doubt, 3D printing technology has been a breakthrough for many years. It is also a rapid prototyping technology that has caused concern within the community recently. A digit technology material printer is used for 3D Printing. It is versatile enough to create everything, from paper towel holders to smartphone cases. The development and production of high-tech products are being done in the areas of medical, household, and military technology. The 3D printer is now a household item. This printer has many medical benefits, including the ability to create new body parts and clinical trials. There are negative effects, such as the decline in mass manufacturing.

The History of 3D Printing3D Printing has a lower impact on the environment than traditional manufacturing, which is one reason it was invented. People have become increasingly aware of the dangers of environmental pollution in recent years. Therefore, environmental protection has become more important. 3D Printing helps reduce carbon emissions. Traditional manufacturing produces Waste and pollution. 3D Printing reduces Waste and carbon dioxide. It uses waste residue, water, and gas from cutting, calcining, and welding to make products. It can have a serious negative impact on the environment. The 3D printer is made mainly of renewable, biodegradable material. It is heated through a power supply to melt molten material and then accumulates layers. The efficiency of the utilization of raw materials is very high, without the pollution of poisonous gases or noise, or chemical substances. For instance, 3D printers use PLA (lactic acid). As per Koslow T. (2019), it is a renewable and biodegradable material made from raw materials like corn and cassava. 3D Printing reduces carbon emissions. It uses material that is green and environment-friendly. Another reason to consider 3D Printing is that it is very fast and does not require molds. As per Grieser F. (2016), 3D printing doesn't need to make links and process them and can even be an element of the initial machine. The 3D printer is a method of Printing that makes use of plastic or metal adhesives as printing material and builds on digital models to print layer by layer. The computer connects to the 3D printer, and the resultant illustrations are printed as models. Some more ambitious ideas from laboratories were developed. For instance, Russians are planning to construct an artificial moon base using 3D printing technology, according to Osborne S. (2019). The impact of 3D PrintingOne of the results that come from 3D Printing is a decline in mass manufacturing. Nobody would have believed that manufacturing in the modern age could be accomplished without factories. Because the manufacturing process has factories and machine tools, as well as production lines and economies of scale, it is therefore impossible that industrial production could happen without machines, assembly lines, and supply chains. This isn't the case, and 3D Printing has a significant impact on manufacturing. As per 3DHubs (2019), 3D printing technology is low-cost and can be tailored to the needs. In comparison to mass production at traditional manufacturing lines and traditional factories, 3D Printing can cut down on costs. 3D Printing also helps improve the quality of production as compared to traditional manufacturing. It is frequently used to create customized, better versions of products at a lower cost and often manufacturing-unattainable ones. This is why they are useful. A printer can print various kinds of items and, sometimes, make them into shapes without assembly. It's like a workshop without being a workshop and is creating an entirely new breed of DIY makers. Also, no inventory is required. In the words of Mazzarol T. (2012), "if these technologies become widespread, it's possible that the competitive advantage of low-cost manufacturing economies like China could be diminished". The future impact of 3D Printing will be the medical revolution. As per the US National Library of Medicine (2014) Medical props models, consumables, models and many other items can be printed using 3D printers. Utilizing 3D printing technology, with the help of computer-generated image data, objects can be shaped into solid structures that can be used for medical instruction and operating training. 3D Printing can be used to create entirely new bodily parts like the bionic eye copying and tooth that is antibacterial bone, human bones, the ovary, printing heart, and so on. As per Murphy J. (2018), 3D Printing can create damaged facial tissues, including the nose, ear, skin, etc. It can also produce exact tissues that are matched to patients. This allows it to reconstruct the whole face of the patient and can create aesthetic results. The face is converted into 3D computer-generated data, which allows doctors to reconstruct the parts of the patient's body which are missing. As compared to conventional techniques, the method used is more precise, and the choice of material is more diverse. Due to the increasing number of materials that are supported by 3D printing technologies, the advancement of the printing process and the growth of the beauty market, as well as the degree of cosmetic enhancement and facial beauty, are expected to increase. As per Triple J Hack (2019), the world's first 3D-printed heart has been developed. "We've made one step closer to a world in which doctors are able to create replacement organs of your own cells thanks to Israeli researchers announcing they've printed a whole heart with biological material". Advantages of 3D PrintingThis manufacturing process has numerous advantages in comparison to the traditional methods of manufacturing. These benefits include those that relate to design, speed, and cost, among others. A few are mentioned below- 1. Flexible Design 3D Printing permits the Printing and design of more intricate models than conventional manufacturing methods. Traditional processes are governed by limitations on a design that does not apply to the application of 3D Printing. 2. Rapid Prototyping 3D Printing allows the production of parts in a matter of hours and accelerates the prototyping process. This allows each step to be completed faster. If compared with manufacturing prototypes, 3D Printing is cost-effective and faster to create parts since the design can be completed in hours, which allows for every design change to be made at a faster speed. 3. Print on Demand Print-on-demand offers an additional benefit since it doesn't require lots of space for stocking the inventory, in contrast to the traditional processes of manufacturing. This can save space and money since there's no need to order Printing in bulk unless it is required. The 3D design files are saved in a library since they're printed with the 3D model, either an STL or CAD file, which means that they are able to be found and printed whenever required. Modifications to designs can be done at a very low cost by editing individual files, without the Waste of out-of-date inventory and using tools. 4. The most durable and light-weight parts The primary 3D printing material that is used is plastic. However, certain metals may also be utilized for 3D Printing. However, plastics are a better choice because they weigh less than their metal counterparts. This is crucial in fields like aerospace and automotive, where lightweight is a problem and may provide greater fuel efficiency. Additionally, components can be made from custom materials to offer specific characteristics like heat resistance, greater strength, and water resistance. 5. Rapid Design and Production Based on the part's structure and design, 3D Printing can print parts in a matter of minutes, which is more efficient than molded or machined parts. It's not just the manufacturing process that could save time with 3D Printing, but also the designing process is extremely fast. It happens by making STL and CAD designs that are ready for Printing. 6. Minimising Waste The process of making parts requires the components needed to make the part itself, and it is minimal or no waste as opposed to other processes that are made up of large chunks of non-recyclable material. This not only helps reduce the use of resources but also reduces the costs of the materials utilized. 7. Cost-effective As a single-step manufacturing procedure, 3D Printing saves time and thus the costs of the use of various machines to manufacture. 3D printers can be set up and then left to do the work, meaning that there is no requirement for workers to be present throughout the duration of the process. As previously mentioned, the manufacturing process could help reduce the cost of materials because it is only using the number of materials needed to make the component itself with minimal or no Waste. Although 3D printing equipment is costly to purchase, however, you could also reduce the cost by outsourcing your work to a 3D printing service provider. 8. Accessibility 3-D printers have become more readily available, with more local service providers providing outsourcing solutions for manufacturing. It is time-saving and does not require costly transport costs as opposed to traditional manufacturing methods that are produced in countries like China. 9. Environment Friendly Because this technology cuts down on the amount of waste material employed, this method is green. However, the environmental benefits can be increased when you take into account factors like increased efficiency of fuel by using lighter 3D printed components. 10. Advanced Healthcare 3D Printing is currently being utilized in the medical field to save lives through printing parts that are needed for the human body, like kidneys, livers, and heart. The latest developments and applications are being created in the medical field, bringing the greatest technological advancements that result from the use of 3D Printing. 11. 3D Printing in other industries Due to the method's flexibility, 3D printing has applications in a variety of sectors, including- Aerospace The aircraft (and aerospace) industry makes extensive use of 3D printing because it can create lightweight yet geometrically challenging things, including blisks. When compared to conventional production techniques, lead times and material waste are decreased since 3D printing makes it possible to construct an object as one complete component. Robotics Due to its speedy production, design flexibility, and ease of design customization, 3D printing is a great fit for the robotics industry. In order to do this, work is being done to create customised exoskeletons and swift, efficient robots. Disadvantages of 3D PrintingSimilar to almost every other method, there are negatives with 3D Printing that should be considered prior to make use of this method. 1. Limited Materials Although 3D Printing can create items using a range of metals and plastics, the range of available raw materials isn't a complete one. This is because some plastics and metals are temperature-controlled enough to permit 3D Printing. Furthermore, the majority of these printed materials aren't recyclable, and a small percentage are not safe for food use. The issue pertaining to environmental pollution is a major one, as it is very important to adopt sustainable means of technology which doesn't damage the environment in the short run and long run. 2. Limited Build Size 3D printers have limited print areas, which limits the parts that can be printed. Any larger parts will need to be printed separately and then joined after production. The printer will need to print more parts to make larger parts. This will increase the cost and time required as they will have to be assembled and joined together in order to complete one single part. Further, all such parts will be assembled to complete the whole product. Manual labor will also be needed to complete the entire process. 3. Post-processing Large parts may require some post-processing. However, almost all 3D printed parts will need some cleaning to remove any support material and smoothen the surface. After this, only the required finish can be achieved on the product. Waterjetting, sanding, and chemical soak and rinse are some of the post-processing methods. The size of the part, intended use, and the type of 3D printing technology used are some factors that will affect the amount of post-processing that is required. Post-processing can slow down the manufacturing process, even though 3D Printing is fast. 4. Large Volumes 3D Printing has a fixed cost, unlike injection molding, which can produce large quantities at a lower cost. Although 3D Printing is more expensive than other manufacturing methods, once you scale up your production to large quantities for mass production, the unit cost will not drop as much as with injection molding. 5. Part Structure 3D Printing, also known as Additive Manufacturing, allows parts to be produced layer by layer. These layers can be separated by adhering to each other, but they may also separate under certain stresses and orientations. This is especially true when items are produced using fused-deposition modeling (FDM). Polyjet and multijet parts, on the other hand, can be less brittle. Injection molding can be a better option in certain situations because it produces homogenous parts that won't separate or break. 6. Reduction in Manufacturing Jobs The downside of 3D technology is that it could reduce human labor. Most of the production is done electronically and by printers. Many third-world countries depend on low-skill jobs to maintain their economies. This technology could threaten these manufacturing jobs by reducing the need for foreign production. It will escalate the problems of unemployment and poverty. 7. Design Inaccuracies A third problem that 3D Printing could have is related to the type of process or machine used. Some printers have lower tolerances which can lead to parts that are not consistent with the original design. While this can be corrected in post-processing, it should be noted that this will increase production time and costs. 8. Copyright issues With 3D Printing becoming more accessible and popular, there are greater chances for counterfeit and fake products to be created. It will be almost impossible to distinguish the difference. This raises questions about copyright and quality control. Certain steps will have to be taken by the concerned authorities to tackle the issue of quality degradation. Conclusion3D printing technology has been a key component of the original manufacturing technology industry. It is gradually changing our production and lives while also playing an important role in culture, creative design, industry, and biological fields. It also has great benefits for medical research and clinical studies. Within a decade, perhaps the finest hospitals around the globe will have organ printers. This will make organ and tissue printing routine. While it is revolutionary in itself, it could have a certain negative impact as well, especially on countries such as China, which are primarily large manufacturing countries. The mass-manufacturing will decrease and reduce job opportunities. In addition, it may also affect the GDP of many other manufacturing countries. Its pros and cons should be discussed thoroughly before it comes into use as an instrument of mass production. |

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share