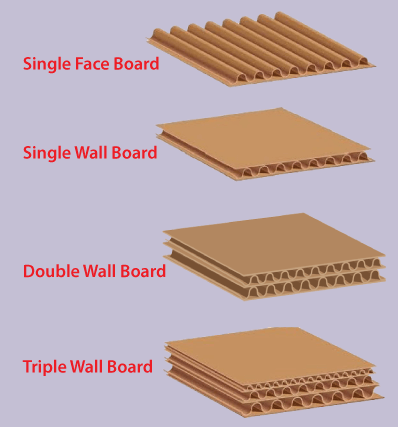

CardboardThe cardboard is derived from the two words card and board. It means that the paper of material in a stiff form. Hence, cardboard refers to heavy paper with some thickness and durability. Cardboards' common uses include tissue rolls, boxes, cereal boxes, packages foods, and drink beverages cartons. The cardboards also make various types of cards, such as invitation cards, business cards, scrapbooks, and postcards that require high durability and binding. The natural color for all types of cardboard, paper, paperboard, cartons, etc., are brown colors. But, cardboards are also available in various colors. The types of walls cardboard are shown below:

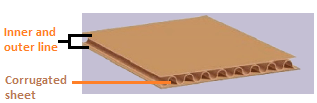

The cardboard is made by inserting a corrugated sheet of paper (curved lining paper) between the inner and outer paper line. It is shown below:

It is also known as Single wallboard. The materials used in making cardboard determine the cost and quality of the cardboard. Let's discuss some of the essential points about cardboard manufacturing.

RecyclingRecycling refers to the task of converting raw materials into new materials. It is becoming a big part of our life to reduce the amount of waste. The recyclable cardboard can be used for domestic or industrial purposes. We can also use it to construct walls and ceils. The ceiling board has a center gypsum and an outer line of paper. Let's discuss the process of recycling the cardboard. It is listed below:

PaperboardPaperboard is thin as compared to cardboard. But, it is thick as compared to paper. It means that paperboard is a thick paper-based material. The advantages of paperboard over paper are foldability and resistance. It can be easily cut and folded. Hence, it is preferred as a packaging material. It is also used in high-quality printing, such as covers of books and magazines. The lamination is also added to the paperboard or cardboard to increase the material's strength and stability. The manufacturing process of paperboardHere, we will discuss the manufacturing process of paperboard.

Cardboard vs. PaperPaper and cardboard are both lightweight materials. But, the paper lacks in stiffness, thickness, and durability. The source of extraction is paper for both the materials. But, the material used is different. Let's discuss some differences between paper and cardboard. It will help us to analyze and differentiate between both items.

Cardboard vs. PaperboardThe paper is thin as compared to the paperboard. So, let's discuss some differences between paperboard and cardboard.

Cardboard boxA cardboard box is the folded form of the cardboard that is used to transport goods. The folded cardboard appears in the shape of a box. The dimension of the box depends on the requirements. The cardboard material is preferred for making boxes because it can be recycled.

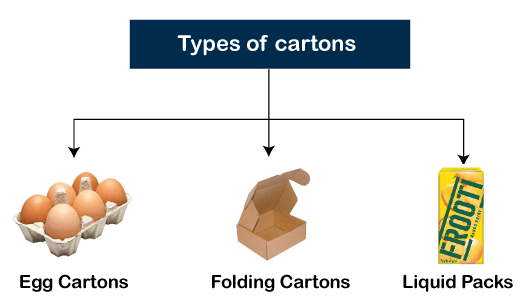

The term cardboard can often be confused with other terms like fiberboard, paperboard, etc. All these terms vary in the thickness of the sheet. The differences between cardboard, paper, and paperboard are already discussed above. The cardboard boxes are created to meet specific requirements like stock, vibrations, moisture, strength, compression, etc. It is due to the weight of the product or material that it needs to carry. The increasing E-commerce business has increased the demand and designs of cardboard boxes. The weight of the material or product inside the cardboard box is limited to a few kilograms or pounds. The thickness of the cardboard boxes depends on the limitation of the cutting machinery. Due to such restrictions, the weight a box can carry is already specified to prevent the cardboard box from collapsing. Opening and closing of Cardboard boxesThe cardboard boxes are generally closed with the help of cello tapes. The tapes' thickness depends on the size and weight of the box and the product inside it. It can be opened with the help of cutters or tear tapes. The folding machines are used in the industries to fold the cardboard. The folded cardboard forms a cardboard box. Corrugated FiberboardIt is also one of the materials used for making cardboard boxes. It is made of one or two layers of linerboards. It is also created from the paperboard. Various parameters define the quality of the corrugated board. It includes impact resistance, bending resistance, box compression strength, moisture content, etc. The raw material used in making corrugated board is paper. CartonCartons refer to a box that is made of paperboard or corrugated cardboard. A carton is generally used as a packaging material for various types of products, such as hardware, food, etc. Types of cartons

There are various types of cartons, such as egg cartons, folding cartons, liquid packs, etc. Egg Cartons The egg cartons are used to store and transport eggs. The egg cartons are pulp made of recycled newspaper molded in the shape of the egg carton. Today, expanded polystyrene is also used to make egg cartons. Folding cartons Folding cartons are flat cartons that can be further folded easily. These types of cartons are manufactured in the form of a flat sheet with pieces. Such pieces are folded to form a carton. Sometimes, the folding cartons are assembled by the packages. There are some machines specifically designed to load and fold the cartons. Liquid packs Liquid packs are used to store juices, milk, etc. It is sometimes made of multiple layers, including a laminated sheet, to prevent the liquid inside it. It also allows easy transportation of such fluids. Applications of cardboardThe applications of cardboard are listed below:

Next TopicResistor color code

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share