Soldering IronA soldering iron is used to join the two workpieces together. It uses solder to fuse such workpieces, which is generally metal. Solder is an alloy material that creates a bond between the two workpieces to be joined. Thus, we can say that soldering iron is a hand tool that uses the alloy material to fuse the two metal pieces. Here, we will discuss the solder, types of soldering iron, Soldering iron kit, soldering process, advantages, and applications of soldering iron. SolderSolder is the alloy material that creates the permanent bond between the two metal pieces to be fused. Let's discuss some of the essential requirements for an appropriate solder material.

Solder can be of various types depending on the workpieces to be joined. The commonly used solder has a melting point around 190 degrees Celsius. The solder with a melting point higher than 450 degrees Celsius is called hard solder. The solder with a melting point lower than 450 degrees Celsius is known as soft solder.

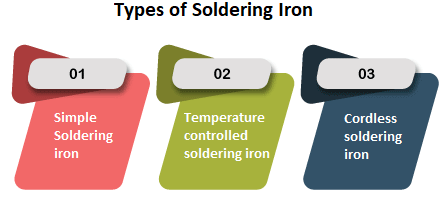

The common solder materials are the alloys of copper, zinc, bismuth, indium, nickel, cobalt, silver, zinc, tin, aluminum, germanium, etc. For example, Hard solder uses alloys of copper with silver. It can also use zinc with a copper alloy. It is commonly used for brazing because it has a higher melting point. Solder was initially made of lead. But, due to environmental concerns, the use of solder is replaced with other alternatives. Types of Soldering iron

Let's discuss the above types of soldering iron in detail. Simple Soldering ironThe simple soldering iron is a low-power iron that is used for small projects. Most of the soldering iron is cheap and comes without a soldering station. The power rating lies between 15 W and 35 W. The temperature is determined by the process of thermal equilibrium, due to which their temperature decreases while soldering large workpieces. Temperature-controlled soldering ironAs the name implies, temperature-controlled soldering iron comes with the soldering station. The soldering station has a temperature knob used to adjust the temperature range as per the requirements. The tip temperature can cool depending on the environment temperature. Hence, most of the soldering iron comes with a temperature sensor that helps to keep the temperature of the soldering tip steady. Some system comes with a thermostat present inside the tip that automatically switches the power of an element. Cordless soldering ironSometimes, the absence of electricity can cause an issue while working with the soldering iron. A soldering iron comes with a battery or a tank with gas combustion. It provides energy to the soldering iron in the absence of electricity. The operating temperature may vary depending on the gas flow. Gas power soldering iron may have interchangeable tips, such as a miniature torch, hot knife to cut the plastic, etc. Soldering Iron kitA Soldering iron kit contains some portable items in a toolbox. The kit includes solder, soldering stand, solder wick, soldering iron, rosin, and soldering iron tips. Let's discuss these common items in detail. SolderAs discussed, solder is the alloy material that creates a bond between the two workpieces to be joined. It is generally in the form of wire, as shown below:

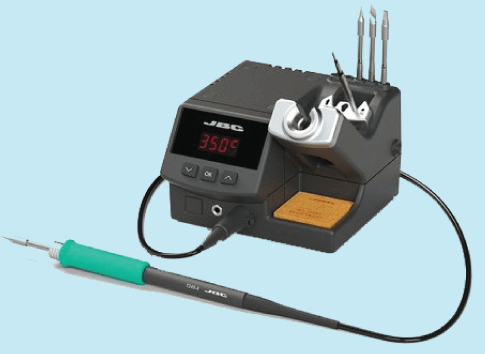

Solder is usually made of lead and tin. When it cools, it creates a strong bond between the two workpieces. Soldering ironSoldering iron comes with various powers depending on the requirements. For example, the small project requires a soldering iron rod of power around 25 Watt, while large projects require soldering iron of power atleast 60 Watts. The role of the soldering iron rod is to provide heat to the solder. The solder under the application of heat melts onto the applied part. After cooling, it becomes hard and creates a bond between the joined workpieces. Hot knifeSoldering iron is also known as a hot knife. Some of the soldering iron comes with interchangeable tips that can be used as a hot knife to cut plastic. Soldering StationThe soldering station provides variable temperature control to the soldering iron. It is connected to the external power supply for its functioning. It has a user temperature control (that allows controlling the temperature range), a soldering head, a tip temperature sensor, and a display. Consider the image of the soldering station shown below:

Soldering standThe soldering stand is used to place the hot soldering iron when not in use. The soldering stand is shown in the below image:

The soldering stand is required because the hot soldering iron can harm the person using it. The stand is made up of metal and can easily hold the soldering iron without causing any damage. Wet spongeMost of the soldering station comes with a wet sponge for cleaning the tip of the soldering iron. Soldering iron tipsThe soldering iron tips help to solder the small areas. The tip can be of various shapes depending on the applications. For example, a chisel-shaped tip has a large surface area for the increased heat transfer, while a round tip has less surface area. The soldering tips with different surface areas are shown below:

RosinRosin flux is a type of flux that is used to clean the surface before soldering. It prevents the formation of the oxide layer on the metal. It comprises 1 to 2% rosin by weight in a flux core. Rosin flux is distinct from organic flux. The organic flux is more robust and hence a better cleaner than the rosin flux. Solder wickThe solder wick is the copper wire supplied on a roll, as shown below:

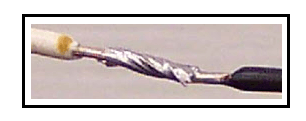

The copper wire of the solder wick is coated with rosin flux. It is used to remove the solder from the components. It is also known as desoldering because it is used to remove the solder. Soldering FluxFlux is a chemical agent that is used to clean metal surfaces before soldering. It is done to avoid any defects after the soldering. It means that flux provides clean soldering. It also prevents the metal surface from re-oxidation. Soldering ProcessLet's discuss the soldering process using the soldering iron hand tool in detail. The soldering iron process requires a solder (material that acts as filler), soldering iron soldering station (for variable temperature control), solder stand (needed to place the hot soldering iron), wet sponge (for cleaning the soldering iron tip), and the required material on which the soldering is to be done. Let's consider an example of joining the two wires. When we switch ON the power supply, the soldering station gets activated. We can adjust the temperature knob accordingly. The temperature range for soldering is upto 450 degrees Celsius. We first need to tie the wires together. We can also take the help of the clutches to hold the wire. After specifying the temperature, the soldering iron gets heated. The specified temperature will appear on display. Bring the solder on the joint between the two wires and place the tip of the soldering iron on it. The solder will melt on the joint between the two wires. As it cools down, it becomes hard and forms a strong bond. We are not required to use any external air source to cool the solder. It will cool automatically within few seconds. Similarly, we can join two metal pieces. We can melt the amount of solder as per the joint's length between the two workpieces. The soldering of two wires will somewhat appear like the image shown below:

Applications of Soldering ironSoldering iron hand tools are used in various applications. Let's discuss the common applications of soldering iron.

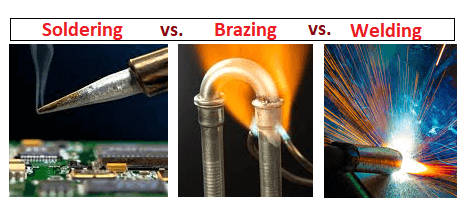

Soldering vs. Brazing vs. WeldingWelding is also a process to fuse to workpieces together by applying heat and pressure to contact the two parts to be joined. Soldering is mostly performed on metal parts, while welding can be performed on metals, thermoplastics, and wood. Brazing is also used to fuse the metal parts but by flowing a metal filler into the joint. The primary difference between soldering and brazing is the temperature. Brazing is a process at temperatures higher than 450 degrees Celsius. Soldering is considered an inexpensive method as compared to welding or brazing. Let's discuss the differences between these three processes.

The differences between soldering and welding are listed in the below table:

Next TopicIs Yahoo a search engine

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share