Synchronous MotorA synchronous motor is a kind of AC motor. An AC motor refers to a motor that takes AC supply as an input and converts it to rotational motion (Conversion from electrical energy to mechanical energy). The primary difference between AC and DC motor, the speed of a DC motor is controlled by its voltage, whereas the speed of an AC motor is a function of the supply frequency. There are two types of AC motors.

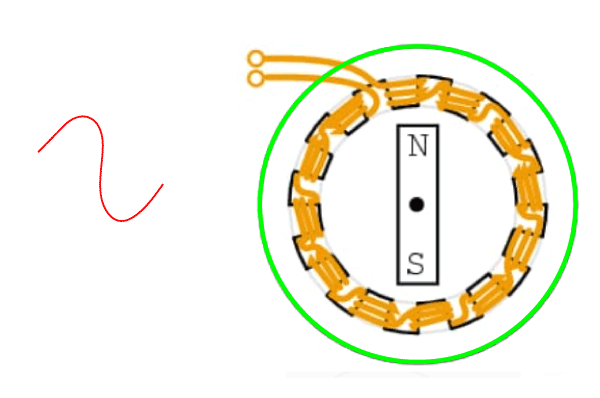

Synchronous motorsA synchronous motor refers to an AC motor that runs at synchronous speed. Synchronous motor is mainly consisting of two parts one is Rotor and other is Stator. The stator is an unmovable part, and the rotor is a movable part of the synchronous motor. The synchronous motor uses a stator just like an induction motor to generate a rotating magnetic field (RMF).

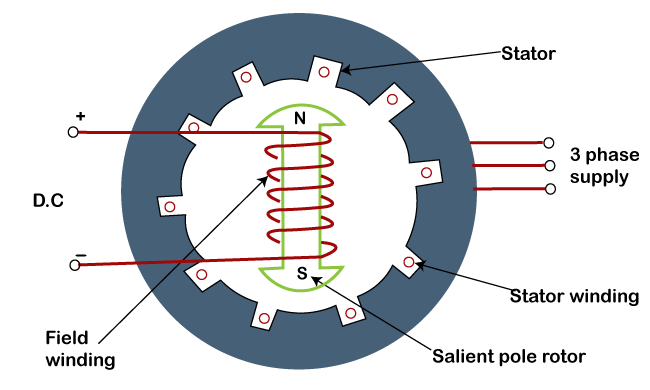

The rotor of a synchronous motor is made up of permanent magnet coils excited by a dc supply. When ac supply is given to the stator, a rotating magnetic field (RMF) is produced. The rotor has poles having different polarities. When this rotor magnetic field interacts with the stator RMF, due to different polarities, stator RMF, and rotor magnetic field locks, since RMF is moving at synchronous speed and the rotor starts to rotate at synchronous speed. So, they are called synchronous motors or constant speed motors. Working Principle of Synchronous Motor A synchronous motor is based on the principle of magnetic interlocking. The starting of a synchronous motor is the same as an induction motor initially excited by 3 phase AC supply given to the stator. If the machine has gone to its maximum speed that is 90% of its speed, a DC Source is given to the rotor.

A 3-phase source is attached to the armature winding, and the armature develops a rotating magnetic field that rotates with a synchronous speed of 120f/P. Once we excite the permanent poles of the field winding created by the DC source that tries to attract the unlike pole of the rotating magnetic poles. If the magnetic poles are attracted and interlocked the rotor continues to rotate with synchronous speed.

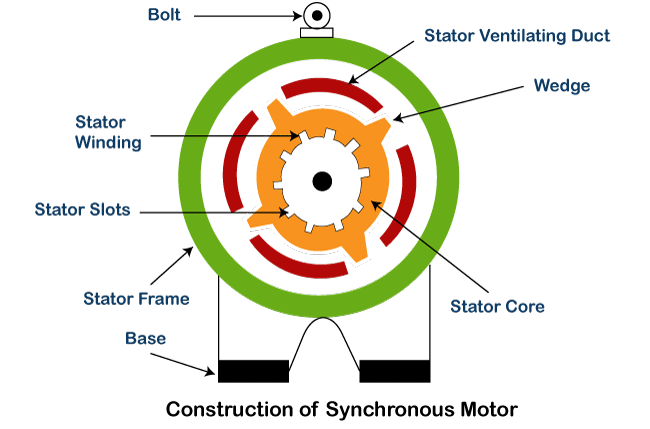

Where, f = frequency and p = no of poles Construction of Synchronous motorSynchronous motor consists of two Primary part; Stator and Rotor

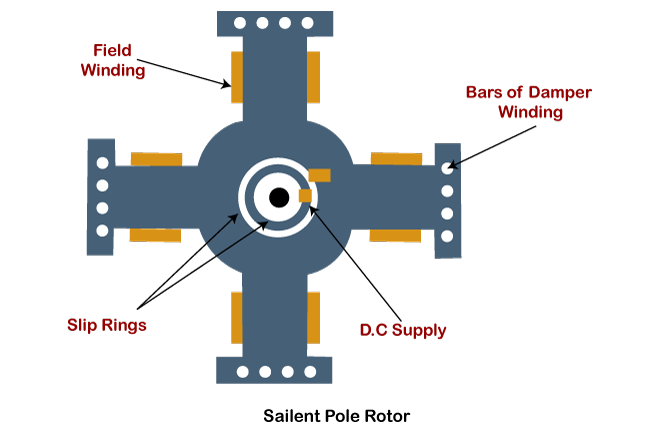

Stator:A stator is a stationary part (Unmovable) of a synchronous machine. The stator comprises a cast iron core which is known as a yoke provide strength to the machine. In a synchronous motor, the armature winding is placed over the stator, which is known as stator winding. The stator core is made up of steel lamination sheets which helps to reduce the eddy current losses. The ventilating ducts are given in the machine frame that resists the high temperature. The winding of the starter is 3 phase winding which is excited by the 3 phase AC supply. Rotor:A rotor is a rotating part (Movable) of a synchronous machine. Rotor incorporates a field winding which is supplied with DC through slip rings. The rotor is divided into two types known as a salient pole and non -salient pole. Most of the synchronous motor uses salient pole type construction. Salient pole Rotor: The salient pole rotor has a large diameter and short axial length. The air gap in the salient pole rotor is non-uniform, and the poles are projecting in outward direction to the rotor surface. The poles are laminated by silicon steel and carry the field winding, and the pole faces are generally provided with slots (Provide support) for squirrel-cage winding. The damper bars are short-circuited at both ends by the copper rings. The working of damper winding primarily provides the starting toque and restricts hunting (Unwanted noise and Vibration of the Machine) in a synchronous motor.

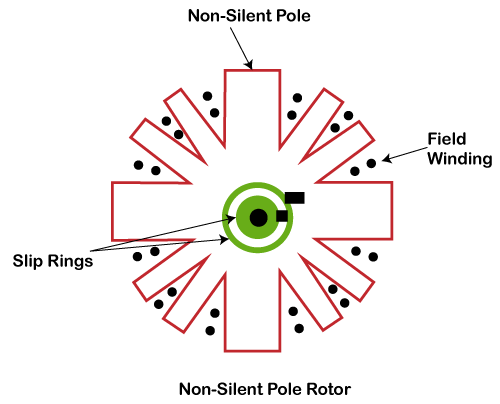

Non- salient pole Rotor: The construction of a non-salient pole rotor is cylindrical, which contains parallel slots to place rotor windings. The slots are connected in series to the slip rings, which are excited by the DC source supply. The non-salient pole is made up of solid steel material. It has a very small diameter and a very long coaxial length with a uniform air gap.

Difference between Synchronous motor and Induction Motor (Asynchronous Motor)

Advantages of Synchronous Motor

Disadvantages of Synchronous Motor

Application of Synchronous motorIn this digital era, a synchronous motor has broad application in day-to-day life. The most common application of synchronous motor is the things that require a constant speed because the power frequency is controlled precisely for the short and long term-for example, Digital and Analog clocks, tape recorders, phonograph turntables, etc.

Next TopicFluid Mechanics MCQ

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share