Difference Between One-Way Slab and Two-Way SlabA concrete slab is a flat, horizontal surface constructed of cast concrete used as a structural element in modern constructions. Steel-reinforced slabs, typically 100 to 500 mm thick are most used to construct floors and ceilings. However, thinner mud slabs will be used for exterior paving. Many residential and industrial buildings have a broad concrete slab on the ground level supported by foundations or directly on the subsoil. These slabs are classified as ground-bearing or suspended.

A slab is ground-bearing if it rests directly on the foundation, otherwise the slab usually suspended. For multi-story buildings, there are various common slab designs.

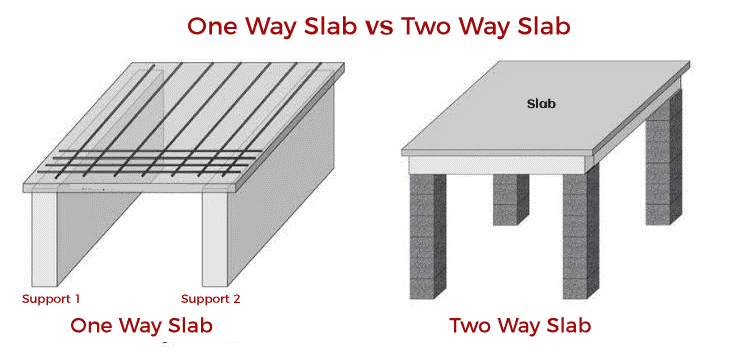

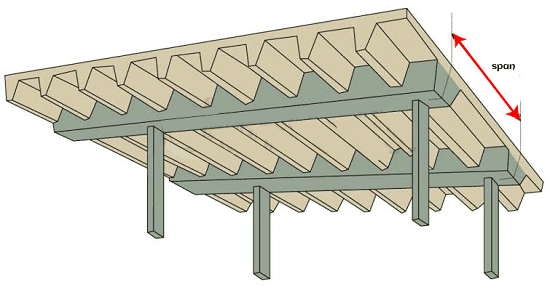

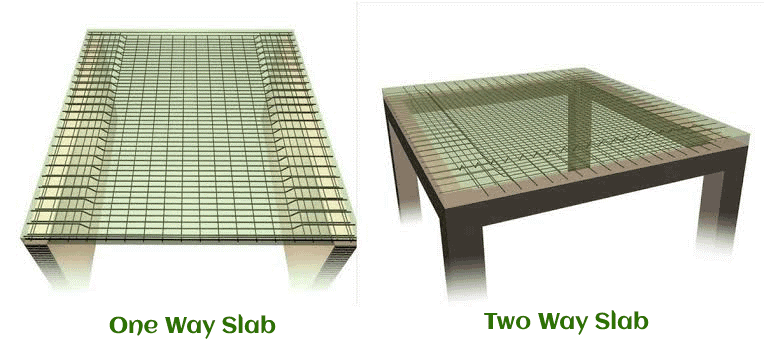

Reinforced concrete slabs are typically abbreviated as "r.c.c. slab" or simply "r.c." on technical drawings. Calculations and drawings are routinely performed by structural engineers using CAD software. Process of SlabThe following steps are typically involved in the slab construction process: FormworkA slab's formwork is typically made up of a set of horizontal and vertical elements put together to create the intended size and shape of the slab. The horizontal members are commonly referred as joists or stringers, and the vertical members are referred as studs or shores. This is the structure that is used to shape the Slab. This is typically accomplished by creating wood, steel, or aluminium forms around the perimeter of the Slab and supporting them with stakes or other forms of bracing. ReinforcementSteel reinforcement bars, or rebars, are mounted within the formwork to strengthen the Slab. The rebars are laid out in a grid pattern according to the structural engineer's specifications. Pouring ConcreteA batching facility mixes the concrete, which is then delivered to the job sites by a mixer truck. When the concrete arrives on-site, it is poured into the formwork and spread out with a screed to ensure an even surface. Before any loads are placed on the concrete they must cure for a specified period. CuringThe Slab must be allowed to cure for a specified period, depending on the concrete type and weather conditions. Curing is the process of keeping adequate moisture levels as well as temperature in concrete after it has been laid to ensure that it acquires its maximum strength and durability. Proper curing is crucial to the slab's long-term performance since it affects its resistance to cracking, shrinkage, and other kinds of damage. JointingControl joints are cut into the Slab to allow temperature changes, expansion, and contraction. These joints must be carefully placed to avoid cracking and to not affect with the structural integrity of the Slab. Control joints, construction joints, isolation joints and expansion joints are some of the joints that can be employed in slab construction. FinishingThe formwork is removed after the concrete has hardened and any imperfections are smoothed away with a trowel or other finishing equipment. It may also be sealed or coated to protect the Slab from moisture and other elements. This final layer can be as thin as cement mortar or as thick as a specialised finishing compound like epoxy or polyurethane. The finishing procedure usually begins with washing the slab's surface and removing any debris or loose particles. The surface's breaks or unevenness are then rectified by grinding or fixing as needed. Once the surface is perfectly smooth and level, a layer of bonding agent can be placed to improve the finishing material's adhesion. One-Way SlabReinforcements in the one-way Slab help to withstand bending moments induced by bending along the long direction of the Slab. Under load, one-way slabs deform into cylindrical surfaces. The structural action found in the one-way Slab is common for supporting opposite sides of a rectangle. One-way slabs come in designs which are ribbed slabs and corrugated slabs. In the case of a one-way slab, increasing the beam width-to-depth ratio and increasing the amount of steel perpendicular to the bending direction will make the one-way Slab more economical and compelling than a two-way slab.

If the Slab is curved in each major direction at a point, the curvature correlates to the bending moments in both directions. Calculating reinforcing necessities for a one-way slab can be time-consuming and complex and the ideal design is only vaguely defined. Even modest project changes may require recalculating the reinforcing requirements. Many factors must be considered while planning the structural architecture of one-way slabs, including:

Advantages of One-Way Slab

Disadvantages of One-Way Slab

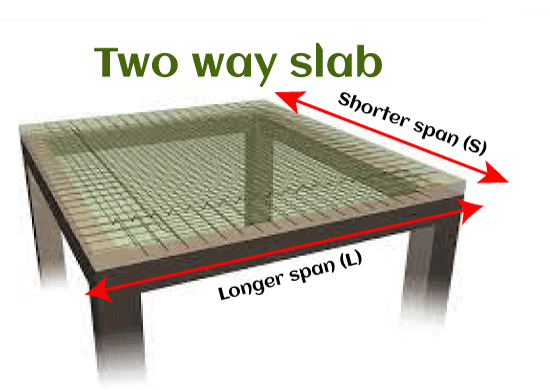

Two-way SlabA two-way slab is a reinforced concrete slab that can span two directions and structurally support buildings and other structures. It is frequently utilized in structures with vast floor plans such as business buildings, lodging establishments, and apartment complexes. However, the ratio of the two horizontal lengths is a crucial factor determining the need for a two-way slab.

When a slab is described as "two-way," it can support weight in both directions, along its length and across its width. This is accomplished by using a system of mesh or reinforcing bars inserted within the concrete to offer strength and stability. Several techniques, such as direct design, equivalent frame, and strip methods can create two-way slabs. These techniques consider elements including the Slab's size, the weights it will bear and the reinforcement that will be applied. Because of their strength, durability, and capacity to cover considerable distances without extra support, two-way slabs are a popular option for many building projects. Two-way slabs give structures tremendous structural stability enabling them to withstand the weight of people within, furniture, equipment, and other loads. They are frequently utilized in multi-story structures because they span great distances without assistance. The two-way Slab uses a variety of reinforced concrete forms, including the following:

Advantages of Two-Way Slabs

Disadvantages of Two-Way Slabs

Similarities Between One-Way Slab and Two-Way SlabOne-way and two-way reinforced concrete slabs are both extensively utilised in building construction. Slabs of both varieties are used to create a level and strong surface for floors, roofs, and other horizontal structures.

Both types of slabs are composed of reinforced concrete, which is concrete mixed with steel reinforcement bars or mesh to strengthen the strength and longevity of the slab. The two kinds of slabs have some of the following similarities Materialsone-way and two-way slabs makes the reinforced concrete, constructed by concrete and steel reinforcing bars (rebars) inserted within the concrete to boost its tensile strength. Load-Bearing CapacityOne-way and two-way slabs are both intended to sustain loads like the weight of people, furniture, and equipment. Each Slab's ability to support weight is influenced by its size, shape, and reinforcement. ReinforcementBoth kinds of slabs have steel reinforcement, which is arranged in a particular pattern to boost the Slab's strength and longevity. PlacementRather than being precast in a factory, both slabs are commonly cast on-site which means they are shaped and poured there. Difference Between One-Way slab and Two-way Slab

ConclusionMoreover, one-way slabs and two-way slabs are reinforced concrete slabs commonly used in construction projects. A one-way slab can only carry loads in one direction, whereas a two-way slab can carry loads in both directions. One-way slabs are generally easier to build and less expensive but have a lower load capacity and are more prone to deflection. Two-way slabs are generally more difficult to build and expensive, but they have a higher load capacity, lower deflection and can span greater distances. One-way slab and a two-way Slab is ultimately determined by the design requirements, load conditions, and support conditions of the specific project.

Next Topicdifference-between

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share