Difference between Soldering and BrazingSoldering and brazing together is one of the methods used to attach two or more pieces of metal. In essence, a junction in metal is produced by hot-gluing the components using an alloy of two or more metals. While the things to be linked are bound at a molecular level to the alloy, which adds significant strength to the joint, the word "glue" here does not simply indicate gluing something together.

The only processes for joining metal that can result in smooth and rounded fillets at the joint's edge are brazing and soldering. The joint surfaces & filler metal are heated above room temperature during both procedures. Both procedures are heating the joint surfaces and filler metal above room temperature. Although the two methods for connecting metal are essentially the same, the temperatures at which they are applied are differently. Brazing filler metals melt at this temperature, unlike solder filler metals, which melt below 450 °C. Soldering:The soldering process involves heating two or more metal components to a temperature where a filler metal known as the solder melts and flows into the junction, establishing a reliable mechanical and electrical connection.

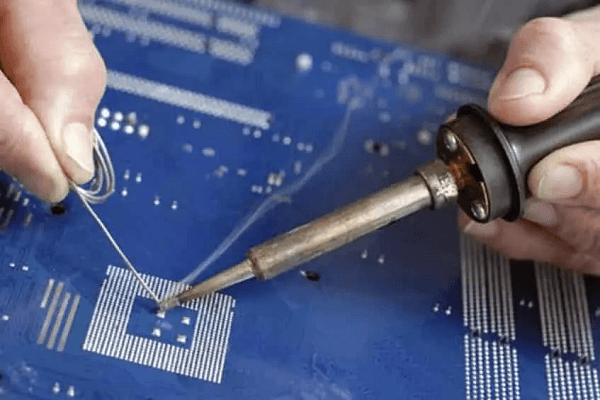

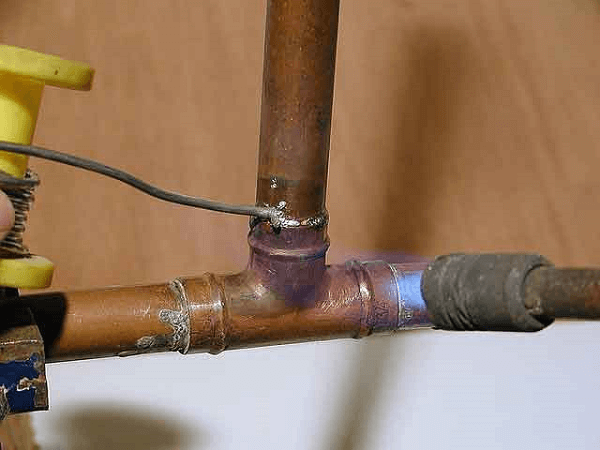

Solder melts at low temperatures of up to 450°C when used with a soldering iron. Part distortion and heat damage to delicate components are reduced since the filler metals melt at low temperatures. Solder joins metal components by bonding to them when it has fully solidified. The most popular variety of solder is made of lead and tin alloy. The electronics industry regularly uses solder to connect wires, capacitors, resistors, and other components to the connecting plate. Together with other metalworking processes, it is used in plumbing and jewelry-making. In contrast to welding, which includes melting the base metal to produce a fusion, soldering does not entail melting the base metal. Because it may be used to join various metals and is appropriate for delicate work, soldering is commonly used. Brazing:By heating two or more metal components to a temperature above their melting point but below the melting point of the base metal, a process known as brazing is used to unite the pieces. The filler metal or brazing alloy is then heated and melted after that.

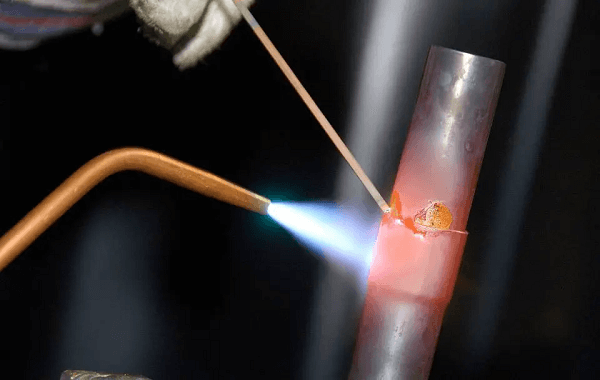

This pours into the gap where the two pieces of metal meet through capillary action. Materials like metals, ceramics, glasses, plastic, and composite materials are typically employed in this procedure. Although the parent metal of the linked components is not melted, this form of metal bonding is more powerful than fusion welding. So, this method requires more heat input than other soldering techniques such as mechanical fastening, adhesive bonding, solid-state joining, welding, etc. It's often utilized in plumbing and metalworking applications and the manufacturing of airplanes, automobiles, and HVAC systems (heating, ventilation, and air conditioning). In various ways, brazing is superior to other connecting methods, like soldering. It can generate a robust, leak-proof junction and a neat, appealing finish and combine different metals with different melting points. Brazed joints can also be easily dismantled if necessary without endangering the integrity of the component pieces. The Difference Between Soldering and Brazing are as follows:Brazing and soldering terms:

Although they are utilized in distinct joining circumstances, soldering and brazing are metal joining methods used to join two metals, whether similar or dissimilar. A form of welding called brazing is used to fuse two pieces of metal by melting a metallic filler and pouring it into the junction. One of the earliest techniques for combining metals, soldering enables the electrical connection of many electronic components, including wires, capacitors, resistors, etc. Moreover, the junction is filled with a filler metal called solder, which forms an alloy at the metal's surface but doesn't melt the base metal. Temperature:The terms "soldering" and "brazing" refer to a class of metal joining procedures in which two or more metals, whether similar or dissimilar, are joined by melting and injecting a filler metal into the joint. Near the fusion temperatures used in welding, brazing is done at these temperatures. The fundamental difference between the two methods of connecting metals is the temperature during each procedure. Both approaches are fundamentally the same. Most work is done when the temperature is above 450 °C but below the metal's critical temperature. However, filler alloys used in the soldering process have melting points lower than 450 °C (840 °F). Strength:In many cases, brazed junctions are stronger than soldered joints. Because of the higher temperature in the brazing process, the filler metal and the joined components can form a stronger metallurgical bond. Clearance:Unlike brazing, which requires a larger clearance, soldering needs a little space between the metal pieces to be bonded. This is because brazing demands a higher temperature than welding, which may result in the metal components expanding and contracting. So that the movement may happen, there needs to be a bigger opening. Cost:Because of greater temperatures, more expensive materials, and specialized equipment required for brazing, the cost of brazing is typically higher than that of soldering. Applications:- Soldering is the method most frequently used in the industry to establish a durable connection between electronic components. It is frequently used in plumbing projects, electronics, crafts, engine repairs, and metal activities, from jewelry to flashing. It is a connection point for wires and leads on switches and other components. To ensure that the filler metal adheres properly to the metal pieces during brazing, flux is added to encourage wetting and eliminate oxides from the base material. Most of the time, it links all sorts of metals except magnesium and aluminum. The auto industry also makes use of it. Differences:

Conclusion:The two processes most frequently used to join two or more pieces of either similar or different metals together are brazing and soldering, both of which involve melting filler metal and injecting it into the joints. Both procedures are quite similar, except that brazing must be done at temperatures higher than 450 °C (840 °F), whereas soldering employs filler alloys with melting temperatures lower than that. Soldering is frequently used in the following fields: plumbing, electronics, crafts, engine repairs, and metals (from flashing to jewelry). Brazing is mostly utilized in mechanical industries, such as the automobile industry, to join all types of metals. The heat source used for brazing is a gas blowlamp since it can produce more heat than any of the other soldering techniques.

Next TopicDifference Between

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share