Difference Between Thermoplastic and Thermosetting PlasticWhat is Thermoplastic?Thermoplastics are an intriguing family of materials that can be bent and moulded into a wide range of shapes by applying pressure and heat. Because of their lightweight, robustness, and affordability, they are becoming more and more common in manufacturing. They are very adaptable, with uses ranging from consumer items to aerospace components. The fact that thermoplastics may be recycled and reused in contrast to their counterparts, thermosetting plastics, which are virtually "set" once they have been moulded, is one of their most amazing qualities.

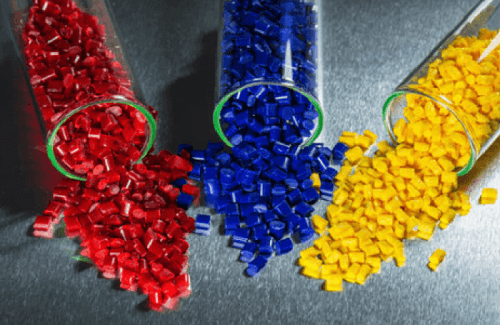

The structure of thermoplastic materials typically consists of long, linear or branched polymer chains held together by relatively weak van der Waals forces. These forces allow for easy movement of the polymer chains when heat is applied, which results in the softening and melting of the material. When cooled, the polymer chains solidify, and the material regains its original properties. There are numerous varieties of thermoplastics, each with special characteristics and uses. Polyvinyl chloride (PVC), polystyrene (PS), polypropylene (PP), and polyethylene (PE) are a few of the most popular varieties (PVC). From water bottles and plastic bags to automobile parts and medical equipment, these materials are used in a wide variety of products. Thermoplastics, however, may be extraordinarily beautiful as well as being highly functional materials. To produce a variety of aesthetic effects, they can be coloured, or even textured. Examples of ThermoplasticThermoplastics are a family of polymers that can be repeatedly melted and remoulded without significantly changing chemically. Examples of thermoplastics include the following:

These are just a few examples of the many types of thermoplastics that are commonly used in various industries. Each thermoplastic has unique properties and characteristics that make it well-suited for specific applications. Thermosetting PlasticWe frequently picture materials for plastics as ones that can be repeatedly melted down and rebuilt. Thermosetting plastics are a different class of plastics that are equally significant but have different features. These materials are vital to many different sectors of the economy, from electronics to construction, and they have special qualities that make them the best choice for particular uses. In Simple words, it is a plastic that solidifies and takes on a permanent "set" in shape as a result of a chemical reaction that occurs when it is heated. As a result, unlike thermoplastics, thermosetting plastic cannot be melted down and reshaped after being moulded into a certain shape. Instead, it keeps its shape and characteristics forever. Its strength and durability are two of thermosetting polymers' main advantages. They can tolerate extremely high temperatures and pressures and are very hard to harm once they have set. They are therefore perfect for applications requiring abrasive environments, like those in the automotive, marine, and aerospace industries. Plastics that are thermosetting can also be moulded into intricate shapes, which is a benefit. They can be moulded into elaborate and detailed shapes that are either challenging to achieve with thermoplastic. Because of this, they are perfect for use in ornamental or creative applications like sculpture or handmade jewellery. The structure of thermosetting plastics consists of highly cross-linked polymer chains held together by strong covalent bonds. These bonds make it difficult for the material to melt or deform when exposed to heat. Once heated, the material undergoes a chemical reaction, known as curing, which forms strong covalent bonds between the polymer chains. This results in a rigid, highly durable material that cannot be remolded or reshaped. Thermoset polymers do have certain downsides despite their great advantages. Most importantly, unlike thermoplastics, they cannot be recycled or reformed after being moulded. So, it is necessary to dispose of any scrap or waste material correctly, which might occasionally be difficult. Toxic fumes and gases can be released as a result of the chemical reaction that happens when thermosetting polymers are heated, thus it's crucial to take the proper safety precautions when handling these materials. To safeguard both the environment and the workforce, proper ventilation and protective gear are crucial. Examples of Thermosetting PlasticsHere are some examples of thermosetting plastics:

Difference between Thermoplastic and Thermosetting PlasticHere's a table comparing some of the key differences between thermoplastics and thermosetting plastics:

Applications of Thermoplastic:

Applications of Thermosetting Plastics:

ConclusionIn the end, both thermoplastics and thermosetting plastics have their place in our modern world, and both play important roles in our daily lives. Whether we are working in construction, manufacturing, or the arts, understanding the properties and applications of these materials can help to make informed decisions about the best materials to use for your projects. And as technology continues to advance, it is likely that new and even more versatile plastics will be developed, opening up new possibilities for innovation and creativity.

Next TopicDifference between

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share