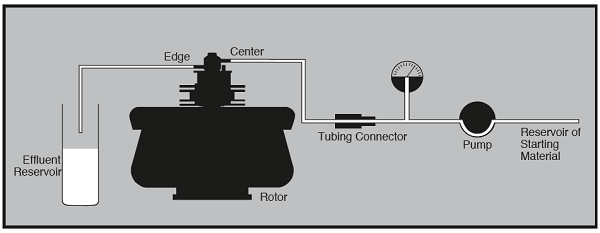

Centrifuge Machine DefinitionIntroductionA centrifuge is a machine or device that separates a liquid mixture based on its density, size, and shape using centrifugal force. The structure of this machine includes a motorized rotor that rotates at a high velocity of 1000 to 2000 revolutions per minute (RPM), by which the centrifugal force is generated. Then this force impels the sample to the base or bottom of the tube or well. As a result, the dense or heavy particles of the sample are set at the base of the tube, while the light particles of the sample stay at the top of the tube. Centrifugation is used widely in many areas and for various purposes, such as biology, chemistry, medicine, etc. The centrifuge has become an important device for research and development in modern science because of its resilience and efficiency.

What is Centrifuge?A centrifuge is a machine or a device that separates a liquid mixture of different substances according to their density by applying centrifugal force. It is possible because of a high-velocity rotor that quickly spins the liquid sample or mixture within the container. This process causes the different particles of that liquid sample to separate form each other by keeping the thicker components at the bottom and the thinner components on the top of the container. We can say that the centrifuge device is one of the best filters available for scientific applications, like biology, chemistry, medicine, and industry, to separate cells, proteins, DNA, RNA, and other biomolecules and purify and concentrate samples.

Centrifuge Types

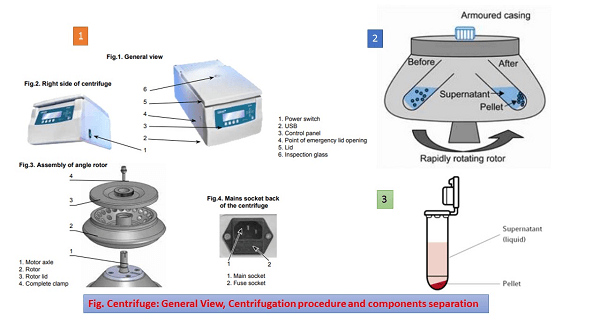

1. Benchtop CentrifugeThe benchtop centrifuge is a popular device in clinical and research labs due to its compact size and ease of use. It rotates tubes around a fixed axis using an electric motor, creating a perpendicular force. These centrifuges are particularly useful for smaller labs with limited space, and various types are available for different applications. A typical benchtop centrifuge comprises a rotor with racks to hold the sample tubes and a lid enclosing the centrifuge's working unit.

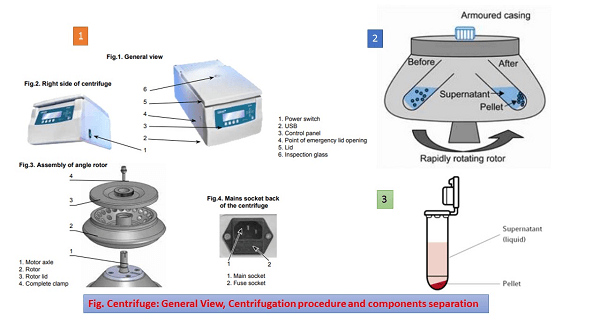

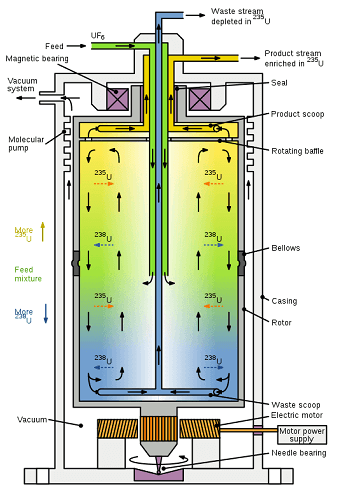

2. Continuous Flow CentrifugeThe continuous flow centrifuge is a quick centrifuge that can spin up big batches of liquid without slowing down their sedimentation rates. With no need to fill and empty tubes between cycles, this centrifuge can separate a huge volume of samples at a high centrifugal force, saving time and decreasing the repetitive nature of the entire process. This type of centrifuge has a shorter path length, which is one of its benefits since it makes it simpler to pellet out the solid portion of the supernatant and keep the process moving quickly. Up to 1 liter of samples can be centrifuged for 4 hours or less using continuous flow centrifuges because they have bigger capacities than conventional centrifuges. 3. Gas CentrifugeOne particular kind of centrifuge that separates gases according to their isotopes is called a gas centrifuge. It operates on the same centrifugal force theory as other centrifuges, separating molecules according to their masses. The extraction and separation of uranium-235 and uranium-238 is the main use of gas centrifuges. Gas centrifuges work by continually circulating gas in and out, unlike batch processing centrifuges. These centrifuges are grouped in cascades for greater separation effectiveness. The gases are moved to the next centrifuge for further processing after being divided based on their isotopes. Due to its higher gas concentration than earlier methods, including gaseous diffusion, gas centrifuges have emerged as the favored technology for isotope separation.

4. Hematocrit centrifugesHematocrit centrifuges are designed to determine erythrocyte volume fraction (RBCs) in blood samples. These centrifuges are particularly useful in various clinical tests, such as biochemistry, immunity, and general blood tests. By providing hematocrit values, hematocrit centrifuges can help diagnose various medical conditions, including anemia, blood loss, bone marrow failure, leukemia, multiple myeloma, and polycythemia, which an elevated erythrocyte count characterizes. Tube samples can be spun at speeds of up to 11,000 rpm and RCFs of 15,000 g with the microhematocrit centrifuge, which operates at high speeds. Although the components of a hematocrit centrifuge are similar to those found in a benchtop centrifuge, hematocrit centrifuges are designed specifically for use with blood samples. 5. High-speed CentrifugeA centrifuge that can operate faster than conventional or other centrifuges is called a high-speed centrifuge. It can spin the sample tube or container at 15000 to 30000 RPM, making it suitable for laboratories with biochemical applications. In this centrifuge, adjustments of speed can be made, as well as adjustments of temperature. Also, various adapters can be fitted in it for different sizes of tubes of different capacities. All three sizes of tubes can be used in it to perform the centrifugation.

6. Low-speed centrifugesIn laboratories, low-speed centrifuges are commonly used to separate particles. Because they lack temperature and speed control systems, they normally function at a maximum speed of 4000-5000 rpm and are typically utilized at room temperature. These centrifuges can be used with swinging buckets as well as fixed-angle rotors. Because of their compact and uncomplicated design, they are perfect for analyzing blood and other biological materials. While operating on the same principles as other centrifuges, low-speed centrifuges are only appropriate for separating simpler solutions. 7. MicrocentrifugesMicrocentrifuges use centrifugal force to separate tiny volume samples ranging from 0.5 to 2 µl. These machines typically run at 12,000-13,000 rpm and are often used for molecular separation of cell organelles such as nuclei, DNA, and phenol extraction. They are also known as microfuges since they use smaller sample tubes than bigger centrifuges. Some types come with adapters that allow you to utilize larger and smaller tubes. Furthermore, some microcentrifuges include temperature controls for working with temperature-sensitive substances.

8. Refrigerated centrifugesRefrigerated centrifuges are the best choice for procedures that call for lower temperatures because they have a temperature control range of -20°C to -30°C. They are a type of centrifuge featuring rotors, racks for sample tubes, and a temperature control unit. These centrifuges are useful for separating various biological compounds since they can produce RCFs of up to 60,000 xg. Their primary use is gathering quickly separable materials such as yeast cells, chloroplasts, and erythrocytes. A chilled centrifuge chamber is also sealed off from the outside, ensuring it meets the conditions necessary for its operations. 9. UltracentrifugesSeparating small molecules like ribosomes, proteins, and viruses that other centrifuges cannot separate is made possible by ultracentrifuges, specialized centrifuges operating at extremely high speeds. They have refrigeration systems to control the heat produced by the rapid spinning. These high-tech centrifuges have been used for both preparative and analytical purposes and have a maximum rotational speed of 150,000 rpm. Large batches of molecules can be separated using ultracentrifuges, which are additionally used in continuous flow systems. They are also helpful for figuring out macromolecules' size, shape, and density in addition to their separation.

10. Vacuum CentrifugeBy combining centrifugal force, vacuum, and heat, a vacuum centrifuge is a piece of scientific equipment used to speed up the evaporation of samples. These centrifuges have a capacity of 148 samples at once. In chemical and biological laboratories, this kind of centrifuge effectively evaporates solvents from samples, concentrating them for subsequent examination. In high throughput laboratories where samples may contain a variety of solvents, they are very helpful. A rotary evaporator's job is to eliminate different solvents and stop solvent bumping. The vacuum centrifuge works by lowering the chamber's pressure, which lowers the samples' boiling points and causes the solvents to evaporate and concentrate the particles that need to be separated.

ConclusionNumerous scientific, medicinal, and industrial applications of the centrifuge have shown it to be an essential instrument. Due to its ability to separate materials according to density and size, centrifuges are now crucial tools in biology, chemistry, and medicine. Using centrifugation, scientists and researchers now separate certain chemicals, organisms, and viruses from intricate mixtures. Additionally, centrifuges are essential in industrial activities, including producing food and beverages, exploring oil and gas, and treating wastewater. The capabilities of centrifuges are constantly increasing thanks to technological developments, and their significance in several industries is only predicted to increase. In conclusion, it cannot be emphasized how important the centrifuge is to modern science and business.

Next TopicEmotion Psychology

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share