Stages of PPCIntroductionProduction Planning and Control is an indispensable part of assembling that includes the meticulous coordination and the executives of different exercises to guarantee the effective and ideal creation of products. A powerful PPC framework assists associations with advancing assets, limiting expenses, and improving general efficiency. In this article, we will dive into the eight phases of PPC, investigating each stage exhaustively to give an extensive comprehension of how it adds to the outcome of assembling processes.

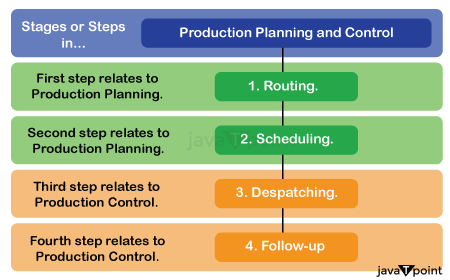

Product Design and DevelopmentThe excursion of creation, arranging, and control starts with the beginning of an item. During the item plan and advancement stage, imaginative thoughts are changed into substantial items. PPC assumes an urgent part in this stage by teaming up with configuration groups to guarantee that the imagined item is feasible for creation. This includes surveying the accessibility of assets, creation capacities, and the similarity of the plan with existing assembling processes. A coordinated PPC framework at this stage helps smooth out the transition from plan to creation, guaranteeing that the plan is not only imaginative but also down-to-earth. Example Envision an organization to spend significant time on electronic gadgets. During the planning stage, the PPC group teams up with item fashioners to guarantee that the picked materials and parts are promptly accessible on the lookout. They likewise evaluate the creation capacities to guarantee that the designed gadgets can be produced proficiently. RoutingWhen the item configuration is settled, the following stage in PPC is routing. Routing includes deciding the ideal grouping of tasks that unrefined components should go through to turn into the result. PPC characterizes the most effective creation course, taking into account factors like machine abilities, work abilities, and the accessibility of hardware. Routing is critical for limiting creation bottlenecks and improving asset usage. It allows materials to move through different handling stages, contributing to a smoother and more coordinated creation process. Example In a car fabricating plant, directing includes deciding the succession of tasks for collecting a vehicle. PPC considers factors, for example, the accessibility of specific gear for assignments like welding or painting, and lays out an ideal course for the undercarriage through different creation stages. SchedulingScheduling is a basic part of PPC that includes deciding the time expected for every activity in the creation cycle. This stage makes a definite creation plan, designating assets effectively and guaranteeing that creation cutoff times are met. PPC considers factors like machine limit, labor force accessibility, and material lead times. A viable creation plan works with better assets for the executives, lessens inactive time, and upgrades general creation effectiveness. PPC assumes a key part in making a practical and reachable timetable that lines up with the association's creation objectives. Example Consider a material plant delivering clothing. PPC makes a creation plan that thinks about the accessibility of talented work, machine limit, and the lead time for unrefined components. By making a sensible timetable, the industrial facility can enhance creation results and fulfill the need for occasional style. DispatchingDispatching is the stage where the arranged timetable is set in motion. It includes appointing undertakings to explicit workplaces and giving the essential directions to start the creation interaction. PPC guarantees that the right materials, apparatuses, and guidelines are accessible to laborers at each workplace. This stage requires viable correspondence and coordination to keep away from postponements and blunders in the creation cycle. PPC goes about as an extension of arranging and execution, working with consistent progress from planned errands to genuine creation exercises. Example In a food processing plant, dispatching includes relegating undertakings to various workstations. For example, PPC guarantees that the elements for a particular recipe are dispatched to the fitting handling stations in the right amounts, smoothing out the creation of food items. Follow-upFollow-up is the stage where PPC screens and tracks the advancement of creation against the arranged timetable. This includes continuous information assortment and investigation to distinguish any deviations from the timetable. PPC guarantees that any issues or postponements are quickly addressed to limit the effect on, by and large, creation timetables. Effective follow-up is essential for keeping up with command over the creation cycle. PPC frameworks frequently consolidate Key Performance Indicators (KPIs) to gauge and assess the exhibition of various creation exercises, permitting associations to pursue informed choices for constant improvement. Example In a high-tech electronics fabricating office, follow-up includes constant checking of creation exercises. PPC frameworks track the advancement of collecting parts into electronic gadgets, giving quick criticism to address any deviations from the arranged timetable and forestalling postpones in item dispatches. Inspection and Quality ControlGuaranteeing item quality is the foundation of PPC. The investigation and quality control stage includes efficiently looking at the created things to distinguish and redress any imperfections. PPC assumes an essential part in setting quality norms, carrying out quality control gauges, and keeping up with consistency in item quality all through the creation cycle. By coordinating quality control into the PPC structure, associations can limit the chance of flawed items arriving at the market. This improves consumer loyalty and diminishes costs related to adjust and guarantee claims. Example In the pharmaceutical industry, review and quality control are basic for guaranteeing the safety of medications. PPC assumes a part in setting norms for the assembling system and directing thorough reviews to ensure that each clump of drugs meets administrative prerequisites and quality guidelines. Inventory ControlInventory management is a complicated part of creation, arranging, and control. PPC is instrumental in keeping up with ideal degrees of unrefined components, work underway, and completed products. Adjusting the need to satisfy client needs with the craving to limit overabundance stock holding costs is a sensitive undertaking that PPC assists with exploring. Effective stock control guarantees that materials are accessible while required, forestalling creation delays, stockouts, or overload circumstances. PPC frameworks use determining and requesting wanting to enhance stock levels and further develop by and large inventory network effectiveness. Example Consider an auto-sequential construction system. PPC frameworks help manage the stock of extra parts and parts. By improving the stock levels for things like tires, motors, and gadgets, the sequential construction system can avoid creation interruptions and limit holding costs. Feedback and Continuous ImprovementThe last phase of PPC includes gathering criticism from the creation cycle and utilizing it to drive nonstop improvement. PPC frameworks investigate information on creation execution, quality measurements, and effectiveness markers. This data is significant for recognizing regions that require upgrading and making changes to streamline the whole presentation arranging and control framework. Continuous improvement is a basic guideline in modern production, and PPC is the component through which associations can adjust to developing economic situations, mechanical advancements, and client assumptions. By embracing a culture of ceaseless improvement, associations can remain competitive and versatile in a powerful business climate. Example In a consumer electronics company, criticism from clients and the creation of information examinations are urgent. PPC frameworks examine client input on item execution and coordinate this data into plans. Persistent improvement drives could incorporate refining fabricating cycles to diminish surrenders or upgrading item includes in view of client inclinations. AdvantagesOptimized Resource Utilization: PPC helps effectively apportion assets like work, machines, and materials. By making practical creation plans and upgrading work processes, associations can avoid underutilization or overutilization of assets. Reduced Lead Times: Viable PPC considers smoothed-out processes and limited delays, which results in more limited lead times from the commencement of creation to the conveyance of completed merchandise. Improved Product Quality: PPC incorporates stages like assessment and quality control, guaranteeing that items satisfy predefined quality guidelines. This prompts a decrease in imperfections and upgrades by and large item quality. Enhanced Customer Satisfaction: With improved creation processes, associations can better fulfill client needs. Ideal conveyances, top-notch items, and adaptability in answering client needs add to expanded consumer loyalty. Productive Stock Administration: PPC helps maintain ideal stock levels, forestalling overload or stockouts. This guarantees that materials are accessible while required, diminishing capacity costs and further developing income. ConclusionThe eight phases of Production Planning and Control structure a thorough system that directs the assembling system from the item plan to the conveyance of completed merchandise. Each stage assumes an essential part in guaranteeing proficiency, quality, and, by and large, progress in underway tasks. A viable PPC framework works with better asset the executives, limits creation delays, improves item quality, and empowers associations to adjust to changing business sector elements. By getting it and carrying out the standards of PPC, organizations can advance their creation processes and stay cutthroat in the present dynamic and testing-producing scene. |

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share