Difference between Alternator and Generator

Introduction:

In electrical power generation, two devices stand out as pioneers in converting mechanical energy into electricity: alternators and generators. Although they share the common goal of producing electricity, these devices operate on distinct principles, offer unique advantages, and find their application in different contexts. This article delves into the world of alternators and generators, unraveling their differences and shedding light on their respective applications. Before discussing the difference between electrical generators and electrical alternators, we must learn about the principle on which they work and their basic functioning.

What is an Electrical Generator?

An electrical generator, often simply referred to as a "generator," is a device that converts mechanical energy into electrical energy. It operates based on the principle of electromagnetic induction, which was discovered by Michael Faraday in the early 19th century. Generators are essential components in various industries, power plants, and applications where a source of electricity is needed.

The basic components of an electrical generator include:

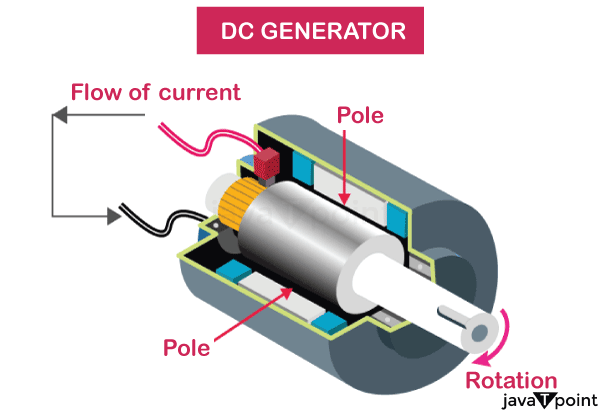

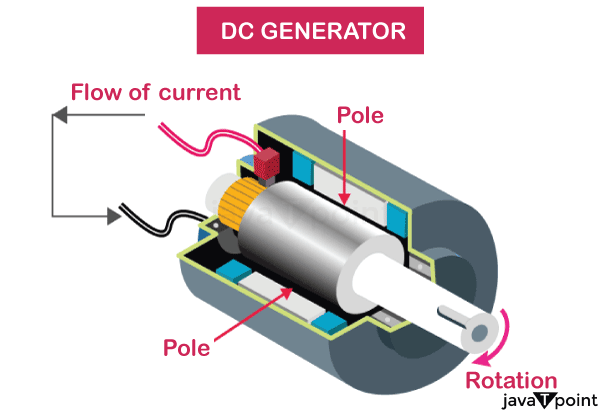

- Rotor (Armature): This is a coil of wire that is mounted on a shaft and placed within a magnetic field. The rotor is the moving part of the generator and is responsible for generating the electrical current.

- Stator: The stator is the stationary part of the generator and contains a set of fixed coils or magnets. The stator's magnetic field interacts with the rotor's movement to induce an electric current in the rotor.

- Magnetic Field: A constant magnetic field is created either by using permanent magnets or by passing a direct current through the stator's coils. This magnetic field is essential for the process of electromagnetic induction.

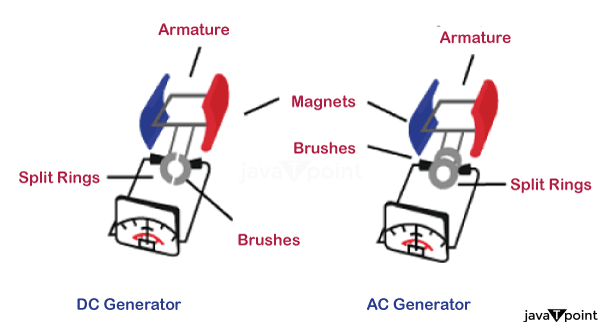

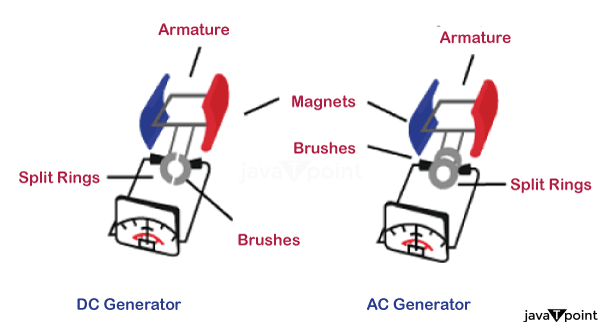

- Commutator (in DC Generators): In direct current (DC) generators, a commutator is used to reverse the direction of the current in the rotor coil as it rotates. This reversing action ensures that the generated current flows in a single direction in the external circuit.

- Slip Rings (in AC Generators): In alternating current (AC) generators, slip rings are used to transfer the alternating current from the rotating coil to the external circuit.

Operation:

When the rotor (coil) of the generator is rotated within the magnetic field created by the stator, the changing magnetic lines of force cut across the wires of the coil. According to Faraday's law of electromagnetic induction, this action induces an electromotive force (EMF) or voltage across the coil. As the rotation continues, the induced voltage causes an electric current to flow through the coil, and this current represents the converted mechanical energy into electrical energy.

Generators are classified into different types based on factors such as the type of current they produce (AC or DC), the method of excitation (field current generation), and their application.

Generators play a crucial role in providing electrical power in various settings, including residential homes, industrial facilities, commercial buildings, and power plants. They can serve as backup power sources during outages, provide electricity in remote areas, and contribute to the stability of electrical grids. While generators have been largely replaced by alternators in many modern applications due to the latter's efficiency and stability advantages, generators still have their place in specific contexts and historical applications.

Generator Applications:

- Backup Power Systems: Generators are commonly used as backup power sources in residential, commercial, and industrial settings. They provide electricity during power outages, ensuring that essential systems and equipment continue to function.

- Telecommunication Towers: Generators are essential for providing continuous power to telecommunication towers, ensuring that communication networks remain operational even in remote locations or during power disruptions.

- Construction Sites: Construction sites often rely on generators to power tools, machinery, and temporary lighting, especially in areas where a reliable electrical grid connection might not be available.

- Emergency Services: Generators are vital for hospitals, fire stations, police stations, and other emergency service facilities. They ensure that critical medical equipment, communication systems, and emergency lighting remain operational during emergencies.

- Remote Areas: In remote or off-grid locations where access to the electrical grid is limited or unavailable, generators can provide a consistent source of power for lighting, appliances, and equipment.

In summary, generators are often used for backup power, construction, emergencies, telecommunication, and remote locations.

Advantages of Generators:

- Backup Power Supply: Generators provide a reliable source of backup power during electrical outages, ensuring that critical systems and appliances continue to function. This is essential for homes, businesses, and facilities that require uninterrupted power.

- Versatility: Generators are highly versatile and can be used in various applications, including residential, commercial, industrial, and remote locations where a stable power source may not be readily available.

- Quick Response: Generators can start and supply power almost immediately after an outage, minimizing downtime and preventing disruptions in operations.

- Longevity: Well-maintained generators can have a long lifespan, making them a cost-effective solution for long-term power needs.

- Independence: Generators can operate independently of the grid, making them suitable for off-grid applications, construction sites, and remote areas.

What is an Electrical Alternator?

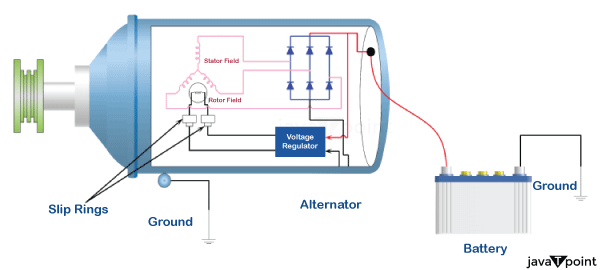

An alternator is an electrical device that converts mechanical energy into alternating current (AC) electrical energy. It operates on the principle of electromagnetic induction and serves as a common source of electrical power in various applications, ranging from automobiles to power plants. Alternators are widely used due to their efficiency, stability, and suitability for modern power generation systems.

Components of an Alternator:

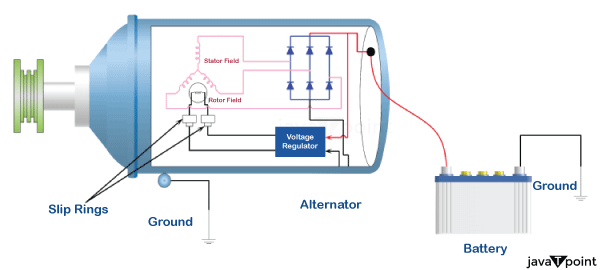

- Rotor (Armature): Similar to a generator, an alternator contains a rotor, which is a coil of wire mounted on a shaft. The rotor rotates within a stationary magnetic field.

- Stator: The stator of an alternator consists of a set of fixed coils that produce a magnetic field. This magnetic field is stationary, unlike the rotating field in some types of generators.

- Slip Rings: Alternators use slip rings to transfer the alternating current generated in the rotating coil to the external circuit. Unlike generators, which often use commutators to convert alternating current to direct current, alternators generate alternating current directly.

Principle of Functioning:

Both alternators and generators utilize the principle of electromagnetic induction for power generation. Michael Faraday first discovered this fundamental principle in the early 19th century and is the basis for how these devices convert mechanical energy into electrical energy.

The principle of electromagnetic induction states that when a conductor (usually a coil of wire) is moved through a magnetic field or when the magnetic field around a conductor changes, it induces an electromotive force (EMF) or voltage across the conductor. This induced voltage causes an electric current to flow through the conductor if the circuit is closed.

In both alternators and generators, a coil of wire is rotated within a magnetic field, or a magnetic field is moved relative to the coil. This motion causes the magnetic lines of force to cut across the wires of the coil, inducing an EMF according to Faraday's law of electromagnetic induction. The induced EMF generates an electric current in the wire, and this current represents the converted mechanical energy into electrical energy.

Alternator Applications:

- Automobiles: Alternators are an integral part of the electrical system in vehicles. They recharge the battery and power various electrical components, including lights, radio, air conditioning, and onboard computers.

- Power Plants: Alternators play a central role in power plants, where they generate AC electricity from various energy sources such as coal, natural gas, nuclear, or renewable sources like hydro or wind.

- Industrial Machinery: Alternators provide power to a wide range of industrial machinery, including conveyor systems, manufacturing equipment, and pumps.

- Electric Grids: Alternators are used in power generation facilities to produce the AC electricity that is fed into the electric grid, ensuring a stable and reliable supply of electricity to homes and businesses.

- Renewable Energy: Alternators are employed in renewable energy systems, such as wind turbines and hydroelectric generators, which convert mechanical energy from wind or flowing water into AC electricity for distribution.

Alternators are essential for automobiles, power plants, industrial machinery, electric grids, and renewable energy systems. Both generators and alternators play critical roles in providing electrical power across a diverse range of applications.

Generators and alternators are both devices used to generate electrical power, and they each have their own set of advantages. Here are the advantages of alternators:

Advantages of Alternators:

- Efficiency: Alternators are typically more efficient than generators because they don't require the conversion of AC to DC. This higher efficiency results in less wasted energy.

- Stable Output: Alternators provide a stable output voltage and frequency, making them suitable for applications where consistent power supply is crucial.

- Low Maintenance: Alternators have fewer moving parts compared to generators, which means they require less maintenance and have longer service intervals.

- Direct AC Output: Alternators generate alternating current (AC) directly, eliminating the need for additional components like commutators and brushes. This simplifies the design and reduces wear and tear.

- Modern Applications: Alternators are commonly used in modern vehicles, power plants, and industrial settings where stable AC power output is essential for various electrical systems and equipment.

In summary, generators are advantageous for their backup power capabilities and versatility, while alternators excel in terms of efficiency, stability, low maintenance requirements, and suitability for modern AC power applications. The choice between generators and alternators depends on specific requirements and the application's characteristics.

Difference between Electrical Generator and Electrical Alternator

Electric generators and alternators are both devices that convert mechanical energy into electrical energy, but they differ in terms of their principles of operation, design features, and applications. Here are the key differences between electric generators and alternators:

1. Principle of Operation:

- Electric Generator: Generators operate based on the principle of electromagnetic induction. They use a coil of wire (armature) that rotates within a magnetic field. The changing magnetic flux induces an electromotive force (EMF) in the coil, resulting in the generation of electrical current. Generators produce alternating current (AC), which needs to be converted to direct current (DC) using a commutator or other means.

- Alternator: Alternators also work on the principle of electromagnetic induction. A rotating magnetic field is produced by the rotor, which induces a current in the stationary stator windings. Unlike generators, alternators directly generate alternating current (AC) output. They do not require a commutator to convert the output to DC.

2. Output Type:

- Electric Generator: Generators produce alternating current (AC) that requires additional components like a commutator to convert it into direct current (DC) for certain applications.

- Alternator: Alternators generate alternating current (AC) directly, making them better suited for applications where AC power is required without the need for conversion.

3. Components:

- Electric Generator: Generators employ a commutator, which is a rotating switch that changes the direction of current in the coil. The commutator requires brushes to make contact with the rotating segments. These components introduce friction, wear, and potential maintenance issues.

- Alternator: Alternators use slip rings to transfer the AC current from the rotating rotor to the stationary stator. Slip rings eliminate the need for a commutator and brushes, reducing wear and maintenance needs.

4. Voltage and Frequency Stability:

- Electric Generator: Generators can have fluctuations in voltage and frequency due to the conversion process from AC to DC and other factors related to the commutator mechanism.

- Alternator: Alternators provide more stable voltage and frequency output because they generate AC directly. This stability is crucial for applications requiring a consistent power supply.

5. Efficiency:

- Electric Generator: Generators are generally less efficient due to the need to convert AC to DC using a commutator and the associated losses.

- Alternator: Alternators are more efficient because they directly generate AC output without the conversion steps required by generators.

6. Applications:

- Electric Generator: Generators are commonly found in older systems and specific applications where DC power is required or where the voltage and frequency stability are not critical.

- Alternator: Alternators are widely used in modern applications, including vehicles, power plants, and industrial systems, where stable AC power output is needed.

The differences between electric generators and alternators stem from their underlying operational principles, output types, design components, voltage and frequency stability, efficiency, and applications. Alternators have gained prominence due to their efficiency, stability, and suitability for modern AC power needs, while generators still have relevance in certain specialized contexts.

Similarities in Alternators and Generators:

Alternators and generators are both devices that convert mechanical energy into electrical energy, and while they have differences in their designs and applications, they also share several similarities:

- Electromagnetic Induction: Both alternators and generators operate on the principle of electromagnetic induction. They generate electricity by moving a coil of wire within a magnetic field, which induces an electromotive force (EMF) or voltage in the coil.

- Rotating Components: Both devices have rotating components. In both cases, there is a rotor (or armature) that rotates within a stationary magnetic field created by the stator.

- AC Output: Both alternators and generators are capable of producing alternating current (AC) as their primary output. This AC can be used to power electrical devices or, in the case of generators, can be converted to direct current (DC) if necessary.

- Essential Components: Both devices have essential components like coils of wire, magnets or magnetic fields, and a means of transferring the generated electrical energy to an external circuit (either through slip rings in alternators or commutators in generators).

- Power Generation: Both alternators and generators are used for power generation in various applications. They serve as sources of electricity in different contexts, from vehicles to power plants.

- Electrical Energy Conversion: Both devices perform the critical function of converting mechanical energy (typically from a prime mover like an engine or a turbine) into electrical energy. This is crucial for various applications where electrical power is needed.

- Voltage Control: Both alternators and generators can be equipped with voltage regulation systems to control and maintain the output voltage within acceptable limits, ensuring a stable power supply.

- Field Excitation: In both alternators and generators, the strength of the magnetic field can be controlled or adjusted to regulate the output voltage and power characteristics.

Despite their similarities, it's important to note that the key differences between alternators and generators lie in the type of output (direct AC in alternators vs. converted AC/DC in generators), their efficiency, voltage and frequency stability, and specific applications for which they are best suited. These differences arise from variations in their designs and components.

Conclusion:

In the world of electrical power generation, alternators and generators stand as stalwart devices that have shaped the way we harness and utilize electricity. Each of these machines has its own unique characteristics, advantages, and applications, offering a spectrum of choices for engineers, manufacturers, and consumers alike.

Generators, born from the pioneering discoveries of Michael Faraday, have been the bedrock of power generation for many decades. Their ability to convert mechanical energy into electrical power has powered homes, businesses, and industries during blackouts and remote expeditions.

On the other hand, alternators have emerged as the contemporary workhorses of electricity generation. Their direct production of alternating current (AC) offers efficiency, stability, and low maintenance advantages.

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now