What are the Advantages and Disadvantages of Friction

Introduction:

When you are riding a bike at a certain velocity and stop peddling, the cycle should keep moving at that speed indefinitely, but it does not. It eventually comes to a stop. Similarly, when you roll a ball on the floor, it rolls for some time before it eventually comes to a stop. Newton's first law states that an object in a particular state of motion will keep being in that state of motion until and unless an external uneven force acts on it. This means that there must be a force that causes the bike you are riding or the ball you have thrown to stop moving after a given amount of time, and not just these objects but every object that moves while being in contact with a surface or a medium follows this principle. This force that brings an object in motion to a halt is known as Friction. In short, friction can be referred to as a force that opposes the relative motion or tendency of motion between two surfaces in contact.

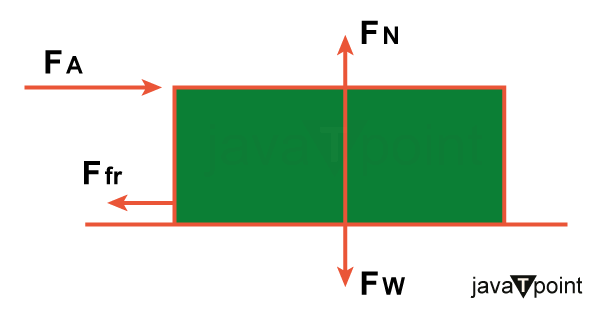

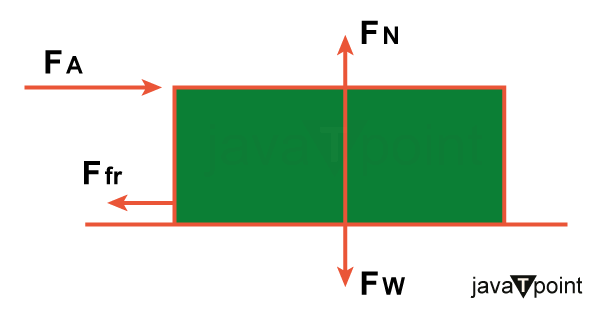

When an object moves or attempts to move against another surface, friction acts in the opposite direction, making it harder for the object to move smoothly. Friction plays a significant role in our everyday lives, influencing how objects slide, roll, and interact with each other.

Friction arises due to the irregularities present on the surfaces of objects. Even seemingly smooth surfaces have tiny bumps, ridges, and imperfections at the microscopic level. When two surfaces slide or move against each other, these irregularities interlock and create resistance, leading to the force of friction.

Types of Friction:

- Static Friction:

Static friction is the force that prevents an object from moving when an external force is applied to it. It arises when two surfaces are in contact but not sliding past each other. The force of static friction exactly balances the applied force, maintaining the object's equilibrium. Once the applied force exceeds the maximum value of static friction, the object starts moving, transitioning to a different type of friction.

- Kinetic Friction:

Kinetic friction, also known as dynamic friction, occurs when two surfaces are in relative motion against each other. Once an object starts moving, kinetic friction acts in the direction opposite to its motion, opposing its movement. The force of kinetic friction is typically lower than the maximum static friction, making it easier for the object to keep moving once it overcomes the initial resistance of static friction.

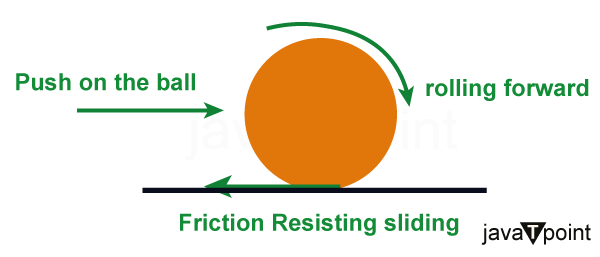

- Rolling Friction:

Rolling friction occurs when an object rolls over a surface, such as a wheel or a ball rolling on the ground. It is generally lower than kinetic friction, allowing objects to roll more smoothly with less resistance. Rolling friction is essential for various applications, like the smooth movement of vehicles and the functioning of machine bearings.

- Fluid Friction:

Fluid friction, also known as viscous friction or drag, is the resistance experienced by an object as it moves through a fluid (liquid or gas). The fluid molecules resist the motion of the object, creating a drag force that opposes its direction of movement. Fluid friction is significant in various scenarios, such as air resistance faced by moving vehicles and water resistance experienced by swimmers.

- Internal Friction:

Internal friction refers to the frictional forces that occur within a substance or material when it is subjected to deformation or shearing. This type of friction is also known as "hysteresis" and is responsible for the dissipation of energy in materials during cyclic loading or deformation.

Friction is a fundamental force that governs how objects interact with each other and their environment. Understanding friction is crucial for engineers, physicists, and designers, as it affects the performance and behavior of mechanical systems. It also has practical implications in various fields, including transportation, manufacturing, and everyday activities. Friction is both a valuable and challenging force. While it can be beneficial in applications such as providing traction, allowing us to walk, and holding objects together, it can also cause wear and tear on surfaces and waste energy.

Advantages of Friction:

Friction, an inherent force present whenever two surfaces come into contact and interact, is a phenomenon that permeates every facet of our physical world. From the simplest of motions to the most intricate machines, friction is a fundamental force that shapes our interactions and experiences. This force, while often viewed in a negative light due to its potential drawbacks, is equally responsible for a vast number of advantages that serve as the basis of our daily lives and technological advancements.

- Traction:

Friction provides the necessary traction for walking, running, and maintaining stability on various surfaces. Without friction, our feet would slide on the ground, making walking difficult and hazardous. Even driving cars would become disastrous as cars would just start sliding on the roads when turning.

- Braking:

Friction is vital for braking systems in vehicles. When the brakes are applied, friction between the brake pads and the rotors or drums slows down the vehicle, bringing it to a stop safely. Even the friction between the tires and the road is essential not only for the steering of the vehicles but also for the braking of the vehicles.

- Rolling Motion:

Friction allows for smooth rolling motion in various applications, such as wheels, bearings, and ball bearings, enabling efficient transportation and machinery. Bearings, which facilitate smooth rotation and movement, rely on friction to maintain alignment and prevent slippage.

- Writing and Drawing:

The friction between the pen or pencil tip and the paper or between chalk and the blackboard is crucial for writing and drawing. It creates the necessary resistance that enables us to leave marks on the paper. Without friction, pens, pencils, chalk, crayons, etc., would just slide off the paper without leaving any marks.

- Functioning of Machines:

Friction plays a significant role in the operation of machines, such as gears, pulleys, and conveyor belts, where controlled friction helps in transmitting power and motion. Friction between gears, belts, and pulleys is fundamental for transmitting motion and power within machines. Gears, for example, rely on the engagement of teeth with controlled friction to transfer rotational energy from one gear to another, enabling speed reduction, amplification, or direction change. Clutches, which engage and disengage power transmission, also rely on friction surfaces to control the motion transfer. Friction between conveyor belts and materials aids in transporting goods within factories and production lines. The controlled friction ensures that materials are moved smoothly and accurately, facilitating automated processes.

- Heating:

Friction generates heat. This property is utilized in various applications, such as starting a fire by rubbing two sticks together or in industrial processes where friction generates heat for welding or metal forming. While heat generation due to friction is a major concern in machinery, especially ones that require faster movement of parts, heat generated due to friction can come in handy in multiple situations. One such situation is being able to create fire by vigorously rubbing sticks or twigs together to generate heat or banging stones together to create a spark. This enables us to start a fire when matches, lighters, or even fuel are unavailable. In remote areas (such as extremely high altitudes or places where snowfall is heavy), where the availability of fuel is scarce, creating fire and heat using friction is beneficial.

- Stopping Sliding Objects:

Friction prevents objects on inclined surfaces from sliding down without any external force, making it easier to control the motion of objects. This also ensures safety and reduces the need to introduce more complex braking systems in certain types of equipment. A good example of this is sporting types of equipment such as roller skates or skateboards. In ice skating, the skater can change the angle of the skates to increase or decrease the amount of area in contact with the surface to alter their speed. This removes the need to carry additional equipment required for braking.

Disadvantages of Friction:

Despite its vast number of advantages that shape not only our daily lives but also the functioning of machines and devices, does not come without its drawbacks. Friction gets a bad name because of its drawbacks. These drawbacks range from energy loss to damage and noise production. It is important to understand the advantages and disadvantages of friction to grasp this force's concept fully. Friction, while an important obstruction, must be eliminated or reduced in certain situations. These are some of the disadvantages linked to friction.

- Energy Loss:

Friction causes energy loss in various mechanical systems. When moving parts in machines or engines rub against each other, some of the mechanical energy is converted into heat due to friction. This results in decreased efficiency and wasted energy. Friction can make it challenging to move heavy objects, especially on rough or uneven surfaces. Overcoming static friction to initiate movement requires a higher initial force, which can be problematic in certain situations.

- Wear and Tear:

Friction leads to wear and tear of surfaces in contact. Repeated rubbing and sliding between two surfaces cause them to degrade, reducing the lifespan of machinery and necessitating maintenance. The most common example is the tires of a car being worn out after excessive use. It is not only costly to get the worn-out tire replaced by newer ones, but wearing out of the tires is also a safety hazard as vehicles become prone to sliding off the road due to reduced traction and take time to come to a stop. Another example is the wearing of brake shoes in vehicles. Due to this, brake shoes need to be replaced on time; otherwise, their ability to stop the vehicles gets reduced greatly, which increases the chances of accidents.

- High Maintenance Costs:

Machines experiencing significant friction often require regular maintenance to replace worn-out components and minimize the effects of wear. This leads to increased maintenance costs and downtime. Wear and tear or damages caused by friction need to be corrected on time; otherwise, operating such devices or machinery becomes a major safety hazard. Using lubricants to reduce friction is a viable and economical option; however, at times, parts need to be outright replaced, which is cost, labor, and time-intensive and leaves the machinery inoperable. The cost and time required to maintain and replace the parts affected by friction only increase as the machine becomes more sophisticated and complicated.

- Increased Fuel Consumption:

Friction between tires and the road surface in vehicles creates rolling resistance. This resistance requires additional energy to overcome, leading to increased fuel consumption and reduced fuel efficiency in vehicles.

- Limiting Speed:

Friction becomes more significant at higher speeds. As a result, it acts as a limiting factor in how fast vehicles and machines can operate efficiently. This limitation can impact the speed and performance of various systems. Friction-imposed speed limits restrict vehicles' performance potential, especially in contexts like racing or high-performance applications where reaching higher speeds is desired. When designing vehicles or machinery, friction-related speed limits can necessitate the inclusion of systems to manage or counteract friction, such as lubrication or advanced tire technology. These additional systems can add complexity and cost.

- Overheating:

In extreme cases, excessive friction can lead to overheating, causing damage to machinery and potentially leading to accidents. Overheating can cause damage to machinery and lead to potential safety hazards, especially in high-speed applications or under heavy loads. Overheating due to friction is very common, especially in fast-moving objects, and is one of the biggest reasons for damage. Overheating due to friction is easily observable in motors used in appliances or machinery. To reduce this friction and prevent damage, lubricants are often used.

- Noise and Vibration:

Friction between moving parts can create noise and vibrations, which may be undesirable in specific applications and may require additional measures, such as damping systems, to reduce noise and vibrations.

Noise and vibrations made by heavy machinery is the most common example. Screeching noise on railway tracks due to the movement and turning of trains is also an example observed in daily life.

Conclusion:

Friction is a force that comes into action when two or more surfaces come into contact. It is a force that opposes the motion an object is trying to undertake; due to this, it can be considered a nuisance, as overcoming this force to get an object in the state of motion requires extra work and energy. Even as the object is in motion, it constantly works against it, restricting the object from utilizing the full potential of the force. Friction also causes energy loss, overheating, and wear and tear. Despite all of the problems that arise due to friction, it is a force that is necessary in our daily lives. Without friction, we would not be able to walk correctly and would keep slipping or falling every time we attempted to walk. Without friction, cars would slip while turning on the road and would not be able to stop when brakes were applied, and this would make driving disastrously unsafe. The title of 'Necessary Evil' given to friction truly fits its description. While it is true that friction causes losses of energy and quality, it would become challenging without it going about our lives while performing simple tasks, such as walking. In conclusion, friction, despite the problem it generates, is a force that is vital to our functioning.

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now