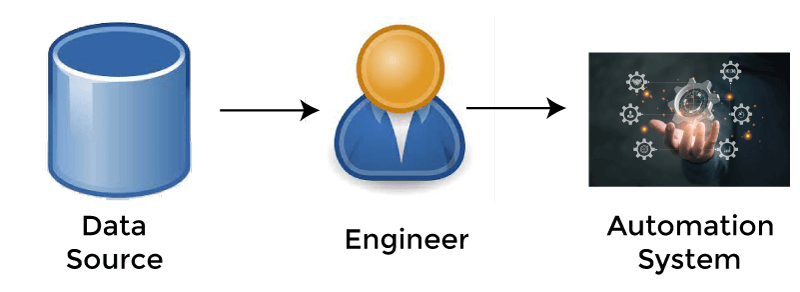

Automation DefinitionThe use of technology to carry out tasks without the need for human interaction is referred to as Automation. Automating common, repetitive, or risky processes aims to boost productivity, decrease errors, and cut expenses. Automation is used more frequently throughout many sectors, including manufacturing, transportation, healthcare, and finance.

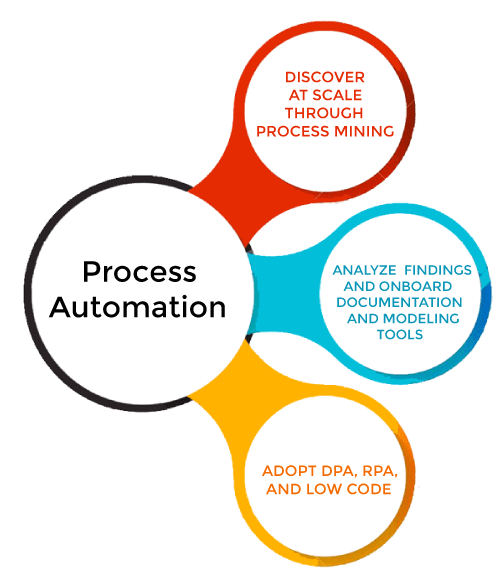

Significant gains in productivity, quality, and safety have resulted from this. But there are drawbacks to automated adoption, including the displacement of human jobs, cybersecurity dangers, and moral dilemmas. This article will examine the definition of Automation and its various forms, advantages, difficulties, and potential. What is AutomationAutomation is the process of using technology to do tasks without the involvement of a human. It entails automating repetitive, risky, or regular processes previously carried out by humans using tools, software, and other technologies. Numerous processes can be automated, including manufacturing, logistics, healthcare, and finance. Automation often uses sensors, controls, and actuators to monitor and manage the functioning of equipment and systems. This enables machines to operate continuously without pauses or relaxation, performing jobs more accurately and efficiently than people. Automation levels can vary from straightforward rule-based operations to sophisticated cognitive tasks requiring sophisticated artificial intelligence (AI) and machine learning algorithms. Automation applications are anticipated to increase as automation technology develops, resulting in considerable productivity, quality, and safety gains across various industries. Overview of Automation's HistoryAutomation has a long and rich history that dates back to the first humans who automated simple chores using levers and pulleys. However, the creation of the steam engine and the power loom in the 19th century marked the beginning of the development of contemporary automation technology.

One of the first devices to automate a manual operation was the power loom, created by Edmund Cartwright in 1784. It greatly advanced the textile industry and used water power to weave cloth. The steam engine, created by James Watt, offered a new source of power that could be utilized to power various equipment later in the 19th century. Henry Ford created the assembly line, and other key developments in automation technology occurred during the 20th century. Automation TypesThree primary categories of Automation exist: Fixed AutomationFixed or hard Automation automates a particular, repeated task or group of operations. The equipment used for fixed Automation is designed to fulfil a specific function or a limited set of functions. Conveyor systems, robotic arms, and assembly lines are a few examples of fixed Automation. Automating Through ProgrammingAutomating through programming uses tools and machinery that may be programmed to carry out various activities or functions. Unlike fixed Automation, this kind of Automation is more adaptable and may be reprogrammed to account for changes in production or other circumstances. CNC machines, industrial robots, and automated guided vehicles are a few examples of programmable Automation. (AGVs). Intelligent AutomationIntelligent Automation automates difficult cognitive processes by combining machine learning, artificial intelligence (AI), and other cutting-edge technologies. This kind of Automation is more efficient and autonomous because it can learn from its mistakes and adjust to changing circumstances. Machine vision, cognitive robotics, and natural language processing are examples of intelligent Automation. The best sort of Automation to utilize will rely on the particular demands and requirements of the application. Each type of Automation has strengths and disadvantages of its own. This may lead to higher customer happiness, better product quality, and less waste. Advantages of AutomationIncreased Productivity Increased production capacity and less downtime are achieved via Automation, which can work continuously without breaks or relaxation. Cost Savings Over time, Automation can result in significant savings by lowering labor costs, reducing waste, and improving manufacturing processes. Better Data Collection and Analysis Automation is more effective than humans at gathering and analyzing vast amounts of data, which enables better decision-making and process optimization. Overall, All the advantages of Automation can significantly boost numerous industries. Industries Using AutomationIndustries that are using Automation with a wide number of industries employ Automation, including the following: Manufacturing The manufacturing industry frequently automates assembly, packing, and quality control processes. Automated guided vehicles (AGVs), programmable logic controllers (PLCs), and industrial robots are frequently utilized in production automation.

Logistics Automation is also utilized in logistics and transportation to complete product sorting, picking, and transportation activities. Automation in logistics and transportation frequently employs automated storage and retrieval systems (AS/RS), automated guided vehicles (AGVs), and automated parcel sorters. Healthcare In the healthcare industry, Automation is employed for jobs including patient monitoring, medication dispensing, and surgical operations. Healthcare automation frequently uses robotic surgical, medical imaging, and laboratory automation systems. Banking and Finance Banking and finance use automated activities like fraud detection, account administration, and customer care. Banking and finance automation frequently uses chatbots and robotic process automation (RPA). Construction Automating processes like site preparation, concrete pouring, and demolition are common in this industry. Construction automation frequently uses robotic bricklayers, autonomous construction vehicles, and 3D printing technologies. Overall, as technology develops and the advantages of Automation become clearer, Automation is becoming more common in various industries. Challenges in implementing AutomationWhile Automation has numerous advantages, there are also several difficulties that organizations may need help with when putting it into practice. The following are a few of the most typical problems: Cost Implementing Automation can be expensive for small and medium-sized enterprises. There may be ongoing maintenance costs in addition to the high initial gear, software, and installation expenditures. Integration It may be necessary to integrate several systems and technologies to automate a process, which can be difficult and time-consuming. It is not easy to make sure that various systems can interact with one another and collaborate effectively. Impact on the Workforce Job losses due to Automation may concern workers and the general public. Organizations must think about managing the effects on their workforce and, where appropriate, promote retraining and reskilling. Resistance to Change Workflow and process changes brought on by Automation may be faced with opposition from staff members accustomed to doing things a certain way. Organizations need to manage change and explain the advantages of Automation to get employee buy-in. Maintenance and Support An automated system needs constant upkeep and assistance after installation. This may be easy if maintaining the system calls for specific abilities or knowledge.

Security Automation may make it more likely that data breaches and cyberattacks will occur. The security and protection of automated systems against potential attacks are the responsibility of organizations. Implementing Automation can be difficult and requires careful planning, money, and supervision. Before deciding to deploy Automation, businesses must balance its advantages against the risks and difficulties that could arise. Technology of AutomationAutomation is projected to progress technologically and become more widely adopted across various industries. The following trends could have an impact on how Automation develops in the future: Increased Use of Artificial Intelligence Artificial intelligence (AI) is already being deployed in many automated systems, and this trend will likely grow. More complicated automated activities will be possible as AI develops, and machines will be able to learn from their mistakes. Greater Automation and Robotics Integration Automation and robotics integration is currently taking place in manufacturing, but it will likely spread to other sectors, including logistics and healthcare. Development of New Automation Technologies The Internet of Things (IoT) and blockchain are two emerging technologies that are anticipated to make it possible to automate new processes in logistics and supply chain management. Increased Use of Autonomous Vehicles The use of autonomous vehicles will certainly increase as technology improves and laws catch up. Autonomous vehicles, such as drones and self-driving automobiles, are already employed in several industries. Focus on Human-Robot Collaboration As Automation progresses, more attention will be paid to how people can cooperate with robots and automated systems to produce better results. Ethics and Social Issues As Automation affects the nature of labor even more, it will become increasingly important to consider these issues. These issues include how these changes affect jobs, salaries, and inequalities. Overall, technological developments, novel forms of human-machine collaboration, and a rising emphasis on ethical and social issues are likely to define the future of Automation. Automated Systems ApplicationsNumerous industries use Automation in a wide variety of ways. Listed below are a few typical uses for Automation: Manufacturing

Automation is frequently used to improve productivity, cut costs, and streamline processes. Robots and other automated technologies are used for assembly, painting, and welding operations. Healthcare A variety of applications in healthcare, such as patient monitoring, surgery, and diagnostic testing, use Automation. Robots can help with surgery and perform minimally invasive operations, while automated diagnostic tools can deliver precise results quickly. Transportation The usage of Automation is growing in the sector of transportation, particularly when it comes to autonomous cars. Self-driving vehicles, including automobiles, trucks, and drones, are being created and tested for various uses, including package delivery and cargo transportation. Logistics Supply chain management and operational efficiency are improved by applying Automation in logistics. Automated solutions can be used for inventory management, order picking, and shipping tracking. Agriculture In agriculture, Automation is employed for processes including irrigation, planting, and harvesting. Automated systems can boost productivity, lower labor costs, and boost crop yields. Energy The production, distribution, and maintenance of electricity are all automated tasks in the energy sector. Automated systems can aid in maximizing energy efficiency, decreasing waste, and enhancing dependability. Overall, Automation has numerous applications in various industries, and as technology develops, we may anticipate seeing new and creative applications for Automation in the future. Sustainability and AutomationAutomation has the potential to significantly contribute to the advancement of sustainability and the mitigation of environmental damage. Here are some examples of how Automation might support sustainability: Energy Efficiency By automating procedures like heating, cooling, and lighting in buildings, Automation can help to optimize energy usage and eliminate waste. Automated systems can change their energy consumption in response to variables like occupancy and weather, resulting in significant energy savings. Resource Optimization In sectors like agriculture and manufacturing, Automation can help to maximize the use of natural resources like water and materials. Both automated materials handling and watering systems can minimize waste and increase efficiency. Renewable Energy Automation can aid in expanding renewable energy technologies like solar and wind energy. Automated systems can monitor and control renewable energy production and distribution, increasing effectiveness and lowering costs. Sustainable Transportation By facilitating the development of electric and autonomous vehicles, Automation can promote sustainable transportation. While electric vehicles can be charged using renewable energy sources, self-driving automobiles can minimize fuel use and pollution. Garbage Reduction By automating procedures like recycling and garbage management, Automation can help to minimize waste. Waste can be sorted and processed more effectively by automated systems, reducing waste in landfills. Automation has the potential to considerably enhance sustainability initiatives by lowering energy use, maximizing resource use, and promoting the expansion of renewable energy sources. However, the long-term effects of Automation on the environment and society must be considered. It is crucial to ensure that it is done morally, responsibly, and sustainably. Automation Cost-Benefit AnalysisA helpful method for assessing the possible costs and advantages of deploying Automation in a certain situation is cost-benefit analysis. Here are a few elements to take into account when performing a cost-benefit analysis of Automation: Initial Investment The upfront costs associated with implementing Automation, including those associated with hardware, software, and training, can be high. It is crucial to consider the price of the automation system itself and any additional expenses for setup, upkeep, and support. Labour Costs By eliminating the need for human labour, Automation can significantly lower labour costs. However, it is crucial to consider any extra costs related to retraining staff or hiring new personnel with different skill sets. Gains in Efficiency By lowering errors and accelerating production processes, Automation can increase productivity and efficiency. This can save a lot of money in the long run because it can boost output and decrease waste. Quality Improvements Automation can increase the quality of goods or services by lowering the possibility of human error. Increased customer satisfaction and loyalty may benefit the company over the long run.

Maintenance Costs They need regular maintenance and improvements to keep automation systems functioning and efficient. It is crucial to consider the future costs of downtime or system breakdowns and the ongoing maintenance and support costs. Automation Education and TrainingIndividuals and organizations must receive proper education and training to profit from Automation properly. Key components of education and training for Automation include the following: Basic Technical Skills Technical literacy, data analysis, and programming are among the fundamental technical abilities that those who work with Automation should have a basic understanding of. These abilities can be obtained through training programs or formal education, such as computer science or engineering degrees. Specialized Skills People working with Automation may need specialized skills in fields like robotics, artificial intelligence, or data science in addition to their basic technical knowledge. One can learn these abilities through specialized training programs, certifications, or on-the-job training. Industry-Specific Information Automation is employed in many different sectors, each with special needs and difficulties. People who work with Automation should be well-versed in the procedures, laws, and best practices of the sector in which they are employed. Soft Abilities Because Automation is frequently used in teams, those who deal with it must have excellent problem-solving, communication, and teamwork abilities. These abilities can be acquired through training courses, mentoring relationships, and practical work experience. Continuing Education Because automation technologies are always changing, those who deal with them must continue their education and training to stay abreast of new advances. This can involve participating in online learning classes, attending conferences and seminars, or pursuing further education. By offering mentorship, training programs, and resources for continual learning and growth, organizations can assist in education and training for Automation. Individuals and organizations may maximize the advantages of Automation and maintain their competitiveness in a technological environment that is changing quickly by investing in education and training. Optimal Techniques for Introducing AutomationThe following are some recommended practices for integrating Automation in a company: Define the Scope Before automating anything, it's critical to specify the project's parameters and identify the procedures or jobs that will be automated. This aids in ensuring that the project maintains its focus and that the automation system satisfies the organization's unique needs. Planning and Implementation Process Automation can greatly impact an organization. Thus, involving stakeholders from all areas of the organization is crucial. This comprises supervisors, staff members, IT specialists, and other pertinent stakeholders. Cost-Benefit Analysis Conduct a cost-benefit analysis to assess the potential advantages and hazards of automating processes and ascertain whether the investment will likely be cost-effective in the long run. The upfront costs, labor costs, productivity benefits, quality enhancements, maintenance costs, and return on investment should all be considered in this analysis. Choose the Right Automation SystemThe finest automation system to adopt is one that best suits the demands of the organization. There are many different automation systems available. This involves considering elements like scalability, compatibility with current systems, usability, and security. Plan for Training and Support Because automation systems can be complicated, it's crucial to plan for training and support so staff members can use the system to its full potential. This entails giving users access to support resources, user guides, and training materials. Test and Validate the System Before implementing the automation system, it is crucial to properly test and validate the system to ensure it is reliable and fits the organization's demands. Monitor and Evaluate Performance Once the automation system has been put into place, it is crucial to monitor and assess its performance to ensure it is fulfilling the organization's needs and providing the anticipated advantages. This involves gathering information on key performance indicators, analysing them, and making necessary changes to improve performance. By adhering to these best practices, organizations can successfully use Automation and reap its many advantages, including improved productivity, cost savings, and efficiency gains. Automation Security and Privacy ConsiderationsIt's critical to think about these systems security and privacy implications as organizations depend more on automation technologies. The following are some important security and privacy factors for Automation: Data Security Automation systems frequently rely on data inputs. Thus, it's critical to make sure that data is secure. This includes developing suitable data storage and backup protocols, securing against unauthorized access, and guaranteeing the accuracy and completeness of data. Network Security It's critical to ensure that communications between automation systems and other systems through networks are secure. This entails putting proper security mechanisms in place, like authentication and encryption, and keeping an eye on network traffic for unusual activities. User Access Control Ensuring that only authorized users have access to the automation system is only possible with access control. This entails putting in place suitable user authentication methods, like passwords or biometric authentication, and ensuring that users can only access necessary functions and data. ConclusionIn conclusion, Automation affects how we live and work and has grown to be a significant component of contemporary civilization. Various businesses see considerable advantages from using Automation, including improved accuracy, production, and efficiency. Automation can present certain difficulties, including the effect on the workforce, the expense of adoption, and the requirement for continuous maintenance and support. With new forms of Automation like artificial intelligence (AI), robotics, and autonomous vehicles expected to influence how we live and work, the future of Automation appears bright.

Next TopicCollective Noun Definition and Examples

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share