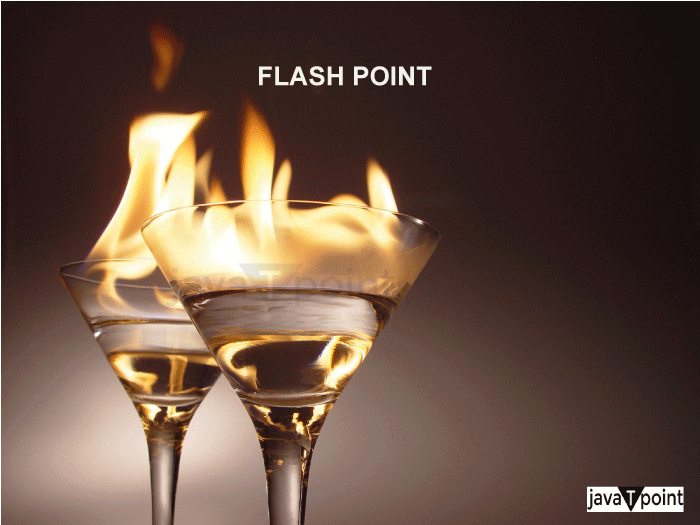

Flash Point DefinitionFlash Point plays a significant role in understanding the Importance of Temperature in maintaining Safety while dealing with flammable liquids in the laboratory. When handling and storing flammable materials, understanding the concept of flash points is crucial for ensuring Safety. The flash point is the lowest point of temperature at which a flammable liquid can generate sufficient vapor to ignite in the presence of an ignition source, such as a spark or flame. This article will explore the importance of flashpoints in Safety and their practical applications.

Flammable LiquidsFlammable liquids are the kind of liquids that quickly catches fire under particular situations, for example, hand sanitizer, nail polish remover, petrol, acetone, benzene, etc. Flammable liquids and gases are frequently used in many laboratories and industries, such as manufacturing, building, and transportation. Although these materials are necessary for many procedures, handling them wrong could result in grave dangers. Preventing the discharge of flammable vapors and maintaining them below the flash point temperature are the keys to safe handling. A liquid's flash point is an indicator of its volatility and varies according to the chemical composition of the fluid. Laboratory testing uses specialized and unique instruments and methods to determine the flash point of a liquid. The Pensky Martens closed cup test is the most often used method, which involves gradually heating a liquid sample in a sealed container while sporadically applying a small flame until ignition occurs. The flash point is the temperature at which the vapor ignites. Pensky Martens Closed Cup TestThe Pensky Martens closed cup tester is a specialized laboratory instrument used to find out the flash point of a given flammable liquid. It is a widely used method for calculating the flash point of petroleum products and other liquids such as solvents, special chemicals, and paints. The device comprises a heating system and a cylindrical cup with a top. A sample of the liquid being examined is put into the cup up to a specified point, often around half the height of the cup. A tiny hole in the cup's lid allows for the introduction of a flame to the sample to check for ignition. The liquid sample is heated during the test at a fixed rate, usually at 5 �C per minute, until the vapor on top of the liquid burns with the flame. The liquid's flash point is determined by measuring the temperature at which the flash occurs. The Pensky Martens closed cup tester has several advantages over other methods of determining the flash point of liquids. Some benefits are discussed below:

However, there are also limitations to the method.

Despite these drawbacks, the Pensky Martens closed cup tester is still a popular way to determine the flash point of volatile liquids. In areas that include handling or transporting flammable materials, it is a crucial instrument for guaranteeing the security of personnel, infrastructure, and the environment. To determine a material's safe handling, storage, and shipping, its flash point is a parameter that must be known. The risk of fire and explosion increases with decreasing flash points. Materials with flash points below room temperature, such as petrol and propane, necessitate extra precautions. On the other hand, diesel and kerosene have lower volatility and are frequently considered less harmful because they have more flash points than at room temperature. To choose the best kind of fire extinguisher for use in the event of a fire, a flash point is a must to care about. Fire extinguishers are categorized according to the kind of fuel they are made to put out, and the temperature of the power determines how effective they are. For instance, Class B extinguishers, made for flammable liquids and gases, can put out fires with flash points lower than 100�F. Contrarily, Class A extinguishers are made for combustible materials like wood, paper, and fabric and are ineffective against flammable liquids. The flammable material's flash point is an essential metric with numerous significant applications in multiple sectors. The following are some of the critical uses for flash points:

A flammable material's flash point has many practical uses in numerous industries. Ensuring combustible items are handled, stored, and transported safely is crucial. It is also engaged in efforts to save the environment and maintain quality. Understanding flash points' significance is essential for accident prevention, environmental protection, and guaranteeing the safe handling of combustible products. What Precautions Should We Take While Handling Liquids that have Low Flash Points? To avoid mishaps and maintain Safety, specific care must be taken when handling liquids with low flash points. The following are some safety measures to be followed when handling liquids with low flash points:

In addition to these safety measures, inspecting tools and containers routinely is critical. ConclusionKnowing the risks of combustible materials requires understanding the flash point. Knowing a material's flash point can help decide the best handling, storage, and transportation practices to minimize ignition and lower the risk of fire and explosion. The Pensky Martens closed cup tester is a specialized laboratory instrument used to find out the flash point of a given flammable liquid. It is a widely used method for calculating the flash point of petroleum products and other liquids, such as solvents and other special chemicals. To prevent accidents, it is also important to guarantee that employees are taught safe handling techniques and have access to the proper safety gear. By understanding the importance of flashpoints, we can work towards a safer working environment for everyone.

Next TopicFoundation Definition

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share