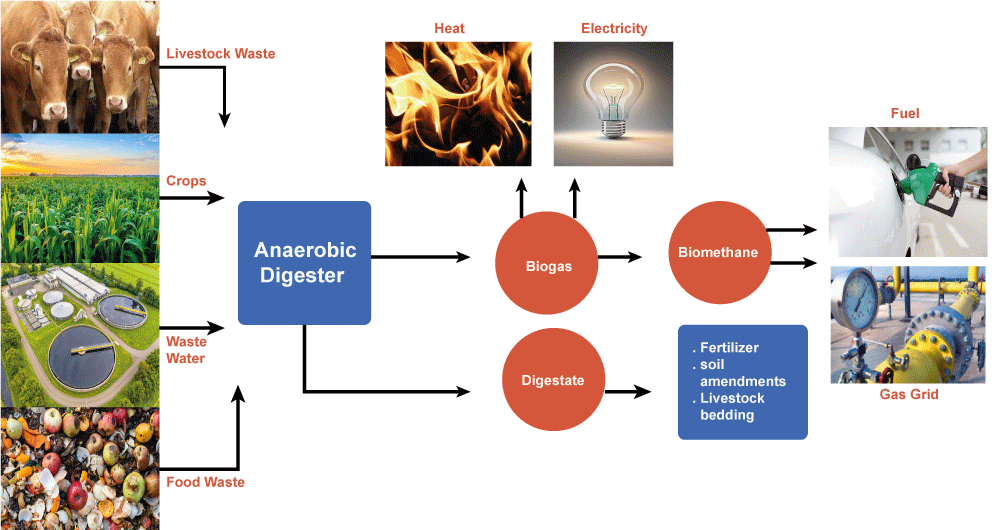

Biogas DefinitionA sustainable energy source called Biogas is produced when certain bacteria break down organic material in anaerobic environments. Methane, hydrogen, and carbon dioxide are all present in it. Agricultural waste, food waste, animal dung, manure, and sewage can all contribute to its production. Anaerobic digestion is another name for the procedure that creates Biogas. Biogas naturally recycles waste materials and transforms them into usable energy, minimizing pollution from the trash in landfills and reducing the impact of hazardous chemicals emitted by sewage treatment facilities. The toxic methane gas produced during decomposition is changed into the less damaging carbon dioxide gas via Biogas. Only a moist climate will allow the organic substance to break down. The trash or organic material dissolves in water to create a nutrient-rich sludge that may be used as fertilizer. Biogas DefinitionAn eco-friendly, renewable energy source called Biogas is created when organic material like food scraps and animal manure decomposes or breaks down. Learn how Biogas is created and how it may be used to generate energy, heat houses, and fuel automobiles.

How is Biogas Made?When bacteria break down organic materials (biomass) without oxygen, Biogas is produced. Anaerobic digestion is the name given to this process. It may be intentionally replicated in containers known as digesters. It occurs naturally everywhere, from the depths of wastewater ponds to the digestive tract. Anaerobic digesters come in two basic categories: Liquid waste effluent ponds are covered, where Biogas collects and is piped for processing, and the other specially designed digesters for semi-liquid wastes, such as fermentation tanks, where the waste is combined, and the digestion process may be managed by heating or chilling or by introducing a bacterial mix to speed up the breakdown process. 30 to 60 percent of the digestible solids are transformed into Biogas during digestion. The following are examples of feedstock for industrial biogas production:

What Are The Components of Biogas?Biogas typically contains: Methane (CH4), which ranges from 55-80% and Carbon dioxide (CO2), 20-40%.Trace gases, such as nitrous oxide and hydrogen sulfide are also present.Methane gas is particularly significant since it can be utilized to create energy because of its high energy content. Methane contributes to climate change 21 times more than carbon dioxide does. It makes sense to trap and burn the methane produced by natural putrefaction rather than allowing it to escape into the sky. Methane is converted into heat and carbon dioxide during combustion. By doing this, you may harness the gas's energy and lessen the effect it has on climate change. Top Biogas ApplicationsThe Top Uses of Biogas (or Applications to Which Biogas is Put) are:

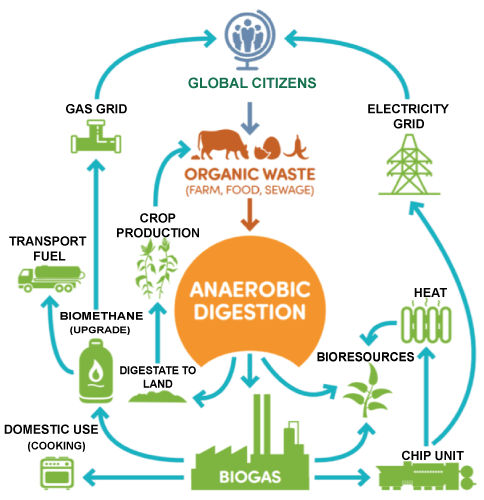

1. Generation of ElectricityThe most frequent of all uses for Biogas is the production of energy. Plant-based Biogas provides a sustainable approach to producing power.Biogas employs a dependable field crop planted and collected by farmers, unlike intermittent wind power or solar energy that is only accessible during the day. Chemical energy is present in Biogas. Thus it is possible to produce electricity from it by first converting it to mechanical energy and then to electricity. Transducers that change energy from one form to another, such as generators and turbines, are used to do this. Since it may be produced on a small or big scale, this power can be utilized both at home and commercially. Connect the gas engine's intake to the biogas supply. The digester used to break down the organic material can serve as the biogas source, which can also come straight from a cylinder containing pressurized gas. Since it is made up of pistons inside which the gas is burned and utilized to drive a shaft, the gas engine is built to operate similarly to one in a car. This is because it converts the chemical energy in the Biogas into mechanical energy through motion. Connect the gas engine and the AC generator such that the AC generator is powered by the revolving shaft. Through the use of magnetism, the motion imparted to the AC generator generates energy. 2. In Combined-Heat-and-Power (CHP) FacilitiesThe use of Biogas to generate combined heat and power ought to be as widespread as electricity production, but adding a CHP plant would require more funding, which may prevent the installation of the additional machinery required to utilize waste heat. Any time that occurs, it should be viewed as a missed chance. From the production of power, there is virtually always a purpose to which the heat may be put. The energy that would otherwise be squandered on cooling fans' surrounding air. Methane (CH4), which normally forms about 60% of Biogas, is the most important component; carbon dioxide (CO2) and minor amounts of other gases make up the remainder. The range for methane concentration is 40% to 70%, and it relies on the feedstock and the effectiveness of the process. The easiest way to use Biogas, which is saturated and includes H2S, is in a boiler to create hot water or steam. The most typical use is where a combined heat and power (CHP) unit uses Biogas to power an internal combustion engine to generate both heat and electricity. There are several Biogas filling stations for automobiles and buses in Sweden, where compressed gas is utilized as a kind of transportation fuel. Additionally, the gas may be improved and used in gas distribution networks. Research is also being done on the use of Biogas in solid oxide fuel cells. Heat may be generated immediately from burning Biogas. In this instance, it is unnecessary to cleanse the biogas' hydrogen sulfide content. The technique typically uses a dual-fuel burner with an 80-90% conversion efficiency. The anaerobic digester, biogas holder, pressure switch, booster fan, solenoid valve, dual fuel burner, and combustion air blower are the system's primary parts. 3. Management of Waste in AgricultureAfter energy, we rank managing agricultural (livestock) waste as the second most crucial use of Biogas. Crop wastes and manure can be digested using either wet or dry methods, either on their own or in co-digestion with other materials. Co-digesting animal manure, the main agricultural waste stream, with crop biomass is one potential method for processing crop biomass in the agricultural industry. Controlled anaerobic digestion of animal manures not only generates renewable energy but also lowers greenhouse gas emissions, nitrogen, and odor from manure management and accelerates nutrient recycling in agriculture. Farmers have a fantastic chance to treat their own waste along with other organic substrates through digestion. As a consequence, farmers are able to correctly manage their own leftovers as well as create additional income by handling organic waste from other sources, selling the resulting goods (such as heat, electricity, and stabilized fertilizer), and/or utilizing them themselves. According to the Chinese Ecological White Paper published by the government in 2002, the nation's overall production of livestock and poultry wastes in 1995 was 2.485 billion tonnes or around 3.9 times the nation's total production of industrial solid wastes. This demonstrates how serious a problem agricultural waste is. If handled appropriately, these wastes are priceless resources, but when they are dumped into lakes and rivers, they cause significant pollution. According to estimates, less than 10% of China's wastewater is now cleaned, and solid waste and organic wastewater are also dangerously polluting 10 million acres of agriculture. Although farmers frequently recycle their animal waste by simply spraying it into the ground, doing so after first undergoing anaerobic digestion results in a far more sanitary process with less smell, a decreased risk of contamination, and much improved nutritional availability. When animal manure is typically left untreated and scattered as "muck" onto fields, Jonathan Letcher writes in his book "Farm Digesters" that approximately half of the nitrogen is accessible for plant absorption. The remaining portion is organic nitrogen that is still contained in the fibrous substance of unbroken cells. Typically, it takes one or more years before 50% of the waste material decomposes through the activity of microorganisms in the soil and may be utilized by the developing crop. On the other hand, microbes in an anaerobic digester cause the manure or slurry to contain organic nitrogen to be converted into nitrates. It may be readily absorbed by plants in this form. Furthermore, when a farm has a functioning biogas plant, the nutrients may be utilized much more effectively by using appropriate farm management to guarantee that the digester output, or "digestate," is dispersed during the growing season. People who observe crops that have been fertilized with digestate usually remark on how well-growing and healthy-looking the crop is. Less insect and disease damage is seen, and the greens appear darker. Many people credit the increase of beneficial bacteria and other microorganisms in the soil following frequent application of digestate for the benefits of biogas plant fertilizer. Farmers that operate their own digesters have stated that using digestate fertilizer decreases their demand for pricey chemical fertilizer by between a third and a half. On a sizable farm, this can translate into three million pounds ($400,000) yearly savings.

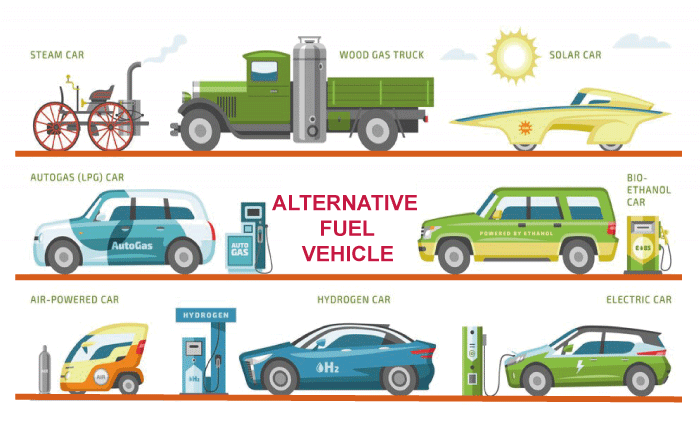

4. Utilising Biogas as a Fuel for Cooking: A Sustainable Energy SourceFor nearly 2.7 billion people who rely on the harmful and inefficient burning of biomass as their primary energy source, the use of Biogas for cooking and baking offers a viable solution. In comparison to alternative fuel combustion methods, such as biomass or fossil fuels, biogas stoves emit the fewest greenhouse gases, provided the Biogas is used appropriately. In this situation, biogas stoves could be able to lessen the effect of rural cooking habits on climate change. The health of marginalized individuals may be improved by biogas-powered stoves and ovens. They provide a fantastic chance to treat organic waste, which frequently poses health and environmental risks, as well as put a stop to the indoor pollution produced in the kitchens of many impoverished people across the world. The poverty cycle may be broken as a result of this. However, the technological viability of consumers creating their own fuel (Biogas) depends (in the first instance) on biogas solutions for cooking. Therefore, a detailed evaluation of the potential and needs of potential consumers is necessary before the technology as a biogas application can be widely adopted. In certain areas, soil erosion and deforestation have been brought on by the manufacturing of fuel wood and charcoal. Population growth and dwindling wood supplies will make the issue worse. A cubic meter of Biogas may take the place of 1.7 kg of charcoal and 5.6 kg of firewood. Furthermore, the digests, a byproduct of the generation of Biogas, may be utilized directly as fertilizer or to create humus (for example, cooking with Biogas whenever feasible)), which can considerably lessen deforestation and assist in offsetting soil depletion. These benefits of using Biogas, however, are reliant on the caliber of the biogas stove, particularly the burner. A sizeable fraction of the methane included in Biogas is discharged into the environment unburned as a result of partial combustion. Methane has a 20-60 times greater impact on climate change than carbon dioxide. The partial combustion of Biogas also causes the exhaust gases to include significantly more hazardous carbon monoxide. People who cook with Biogas may experience improved health (due to, for example, improved indoor air quality and time and money savings). However, in many instances, ensuring the technology's long-term acceptance has proven challenging. But unattended systems and disgruntled users have hindered the adoption of technology in numerous fields. The incorporation of biogas usage into consumers' routines appears to be a crucial requirement (as well as a difficult problem) for assuring the long-term use (and spread) of the technology. There are difficulties involved in switching to Biogas for cooking. The IEA claims that after applying Biogas, families do not just move from one fuel to another when their income rises. Using many fuels simultaneously instead of relying solely on one fuel or technology may increase energy security. Aside from that, people's taste preferences and their experience with cooking using old technology make it difficult to change the way traditional food preparation methods are done. However, over time and on a regional level, families in wealthier nations are typically anticipated to switch from using just biomass for cooking to employing more efficient technologies, with Biogas being one possibility (IEA, 2006, 2008). The widespread use of Biogas is now hampered by low per-capita earnings and a lack of awareness of the advantages of more environmentally friendly fuels. Therefore, funding investments in biogas plants is a challenge, particularly in least-developed nations. The target group's overall reluctance must thus be addressed through financial packages and extra incentives. For instance, in India, the majority of biogas plant applications are located on richer farms with a sizable herd of cattle. 5. Natural Gas Pipeline InjectionIt is necessary to clarify the use of Biogas as a fuel additive to natural gas supply pipes for fossil fuels. Pure gas is typically referred to as "Biomethane" once it has been filtered to an appropriate level for injection into a natural gas pipeline. This type of biomethane injection is desired in many nations where the populace is eager to adhere to climate change mitigation strategies. Compressed Biomethane is referred to as "Renewable Natural Gas" or RNG in the gas sector. In the United States, the potential for RNG and Biomethane in gas applications is essentially unrealized. Only 42 high-BTU landfill gas-to-energy projects are producing RNG, biomethane, enhanced, or pipeline-quality Biogas out of more than 1,000 landfills that might be candidates for biogas production, according to statistics from the Coalition for Renewable Natural Gas. There are only 1,200 operating facilities collecting Biogas to either create renewable electric power or provide transportation fuel for 3,500 potential wastewater treatment plant biogas projects. Only 239 biogas-generating facilities are in use out of more than 12,000 potential agricultural digester projects that may produce the fuel. Via Bio cycle's website Renewable natural gas (RNG) is increasingly being offered to local gas distribution and transmission pipeline companies to buy and/or take delivery into their existing lines for broad distribution. RNG is produced by the anaerobic breakdown of a range of organic resources, including dairy and agricultural waste, wastewater, and landfill sources. The word "Biogas" is used in the natural gas business to describe gas generated directly from digesters or landfills. This gas is frequently burnt on- or off-site in generators to create power or is simply flared. The intended product for inclusion in the natural gas pipeline infrastructure is cleaned Biogas or Biomethan, most widely known as RNG nowadays. Costs linked to the grid, such as injection costs, transportation fees, distribution fees, balancing fees, brokering fees, etc., are associated with connecting to the grid and transferring the RNG from one place to another. However, the ability to transfer the RNG anywhere it may be required gives RNG creators amazing potential. There is a great demand for RNG to meet emission reduction targets in markets where there is a renewable portfolio standard (RPS), a carbon tax, or a cap and trade system for reducing greenhouse gas (GHG) emissions. 6. As a Fuel Replacement for Transportation VehiclesIf compressed and concentrated, conveyance by vehicle is the best use of Biogas. In Sweden, Switzerland, and Germany, compressed Biogas is being utilized more and more often. Since 2005, Sweden has operated a biogas-powered train known as Biogastget Amanda (The Biogas Train Amanda). Autos are propelled by Biogas. In 1974, the British documentary Sweet as a Nut described how Biogas was created from pig dung and demonstrated how it powered a specially modified combustion engine. Around the world, especially in Europe, 12,000 automobiles were reportedly using improved Biogas as fuel as early as 2007. If a fleet of trucks is filled at the same site as the biogas plant, it might be quite advantageous for transportation purposes to fuel the cars with Biogas. If so, there are no expenses associated with moving the Biogas to the location of usage.

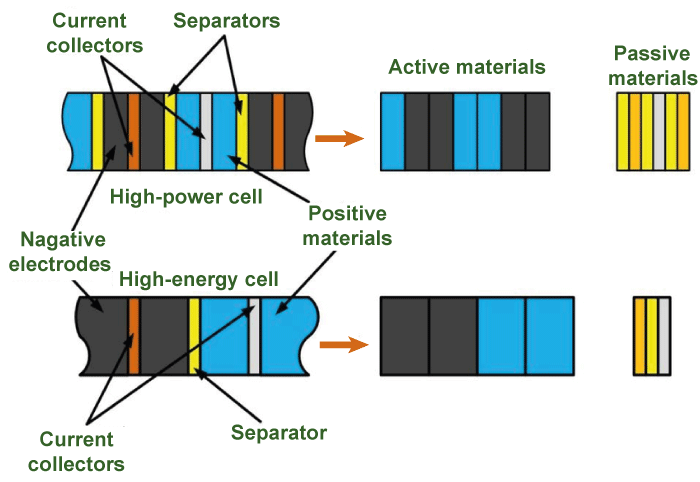

7. Energy CellsTheoretically, a fuel cell might turn Biogas straight into energy. However, this procedure calls for very pricey fuel cells and highly pure petrol. As a result, this solution is still under investigation and is not currently a viable one. It is far more practicable to convert Biogas using a generator to electric power.

Benefits of Biogas1. Renewable Energy SourcesPlants, animals, and people all produce organic stuff. Biogas is a renewable energy source since raw ingredients are easily reproducible. Additionally, it reduces the negative effects of inappropriate garbage disposal. 2. Waste UtilisationIt is better to use the trash and convert them into Biogas than to let them rot in landfills. Because less methane, carbon dioxide, and other greenhouse gases are created, there is less of an environmental risk. Wastes are converted into energy that may be used for cooking, heating, power, and fertilizer. 3. Builds a Circular EconomyHumans and animals both create trash, which includes agricultural residue, animal manure, food waste, and wastewater. If these wastes are not processed properly, damage may result. These organic wastes are transformed into Biogas, which is a more beneficial kind of energy. The wastes are converted into digestate for fertilizer purposes, Biogas for use in vehicles and heating systems, and natural gas for cooking and cooking. 4. An Effective Replacement for Electricity and Cooking in Rural and Developing NationsElectricity availability in some places is restricted, which affects residents' quality of life. They have a good option in Biogas. Both small- and large-scale manufacturing are feasible and easy to set up. Negative Aspects of Biogas1. Limited Technological ProgressThe biogas sector is still in its infancy. To create new technologies and increase manufacturing efficiency, more study is required. Additionally, governments offer additional assistance to well-established energy sources, including solar, geothermal, wind, and hydropower. 2. Dependence on WeatherThe weather has an impact on the generation of Biogas much like it does on other intermittent energy sources (solar, wind). A temperature of 37�C is required for anaerobic digestion to take place. Cold areas demand heat energy to continuously manufacture Biogas. 3. Biogas Power Plants Emit Bad OdoursThe wastes that are processed by biogas plants give out an unpleasant odor. Construction of power stations should take place far from populated regions and other industrial sites. Why is Biogas Useful as a Source of Energy?Since the biological material used to create Biogas will naturally decompose, it is less harmful to the environment to capture the gases that result from this decomposition and use them as an energy source than letting them escape into the atmosphere. Additionally, primarily cyclical, the creation of Biogas is part of a sustainable cycle for handling agricultural waste. For instance, the animal waste generated on a farm may be utilized to create Biogas, which is then used to power agricultural equipment. Risks to Health and Safety from a Biogas PlantIf health & safety considerations are made at every stage of the construction of a biogas project, all of the dangers listed below can be readily managed. The dangers comprise, for instance:

Explosion and FireBiogas and air can occasionally combine to create an explosive gas mixture. Near digesters and gas reservoirs, there is a heightened risk of fire and explosion. Gas leaks, the development of explosive zones, welding, and clogged or frozen pipes, among other things, can cause it.

ConclusionThe anaerobic digestion of organic waste produces Biogas, a renewable and sustainable source of energy. It is a flexible energy source that may be utilized for a variety of tasks, including cooking, heating, and producing electricity. There are several advantages to using Biogas instead of conventional fossil fuels, including improved waste management, lower greenhouse gas emissions, and energy security. A significant step towards a more sustainable and ecologically aware future is the increasing use of Biogas as a source of energy.

Next TopicCenter Of Gravity Definition

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share