Daisy Wheel Printer

It was an impact printer developed by David S. Lee in 1969. The printer consists of a metallic or plastic disk that stores letters, numbers, or special characters that could be printed using the printer.

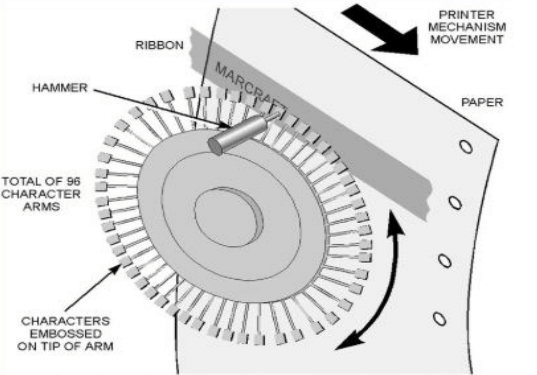

The printer's disk will rotate to the particular character when the user wants to print any character using the printer. The hammer will strike each character into the ribbon, creating an impression of the character on the printing surface.

These printers are no longer used, but they were especially popular in the 1960s-70s. There were several issues with the daisy wheel printer. First, the quality of the print was poor.

The machine made a lot of noise while the printer was and had poor performance. They were replaced by laser printers that produced more speed and efficient prints. Moreover, they were comparatively cheaper than the Daisy Wheel printer.

Daisy Wheel Printing

Andrew Gabor introduced this technology in 1970. The technology required interchangeable per-constructed elements. Each element had 96 glyphs that produced high-quality output. The print was superior to the typewriters. It was also twice faster as these typewriters. Since then, this technology has been used in electronic typewriters, word processors, and desktops. The equipment looks similar to a daisy flower, hence its name, the daisy wheel.

By 1980, daisy wheel printing became quite popular as it produced high-quality text compared to the predecessor technologies.

This technology was also implemented in the Dot-matrix, thermal, and line impact printers. However, it compromised the print's quality and increased the printing speed. It was used where the user required quick prints and could compromise the quality.

Both technologies were replaced when dot-based printers were introduced in the markets. The laser printers provided a wider range of characters or graphics that could be printed using the printer. The daisy wheel printer could print only the set of characters printed on the printer's wheel. This technology is now available in some of the older models of electronic typewriters.

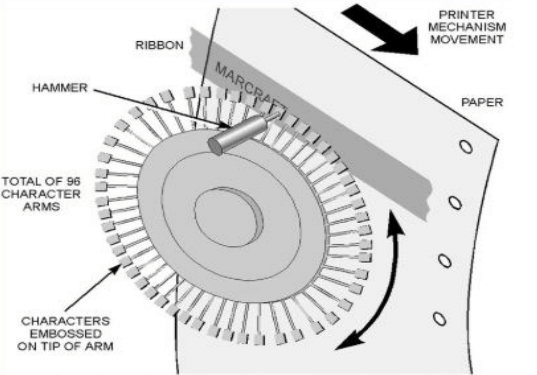

Design of Daisy Wheel Printer

- The key component of the printer is an interchangeable metallic or plastic disk. This disk was similar to a daisy flower, hence the name daisy wheel.

- It had a character set containing the list of all raised characters that could be printed using the printer on each wheel petal. Both the daisy wheel and the hammer of the printer are placed on a sliding carriage, which is somewhat similar to the design of a dot matrix printer. It has a servo motor to rotate the daisy wheel in a position where the character to be printed is between the hammer and the ink ribbon. The hammer hits the raised character on the petal, which produces an ink impression on the paper.

- The printer can print characters with different fonts and sizes by simply replacing the daisy wheel of the printer. The printer enabled the user to use multiple fonts in a single document. Fonts were changed by the printer drivers responsible for positioning the carriage to the center of the plate. It would notify the user to change the wheel of the printer whenever necessary before beginning the printing.

- Thus, if there were several fonts in a document and the changes occurred frequently, it also required the frequent change of the wheel. The change was done manually, which makes using these printers tiring.

- Many daisy wheel printers also allowed the user to print bold characters. This effect was generated by striking the hammer multiple times on the specific character. The servo-based printers advanced the carriage fractionally to make a wider impression on the surface. This made a darker impression than usual, thus giving a bolder effect to the character printed.

- In the cheaper printers, the carriage is performed by returning without a line feed to return at the start of the line, space to all the characters that were not bold, and re-strikes all the characters that were to be given bold effect.

- The imprecision caused due to re-hitting the exact spot after the carriage produced the same result as the expensive servo printer. But it also had a drawback: as the printer aged, the expensive printers produced a darker, bolder effect.

- Like all the other impact printers, the daisy wheel also produced noise while printing.

History of Daisy Wheel Printer

- Arthur Irving Jacobs filed a patent for the design of the daisy wheel, the key component in the daisy wheel printer. The patent for the daisy wheel design was granted in 1889. The daisy wheel was first used in the Victor Index Typewriter.

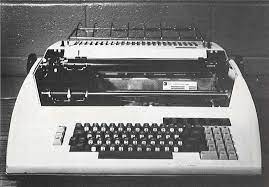

- The first daisy wheel printer was developed by A.H. Reiber, who was granted the patent for the printer in 1939. But a team at Diablo Systems developed the first commercial daisy wheel printer in 1970. The team was led by an engineer named Dr. Andrew Gabor. Two patents were issued in the name of Dr. Andrew Gabor for the daisy wheel printer. This printer was more efficient than the IBM Selectric devices. IBM Selectric Devices were operated at 13.4 cps, while the new printer could work at 30 cps.

- Xerox acquired Diablo the same year of the patent. The new Diablo 360 produced letter-quality output with more speed and relatively less cost. It also provided support for the complete ASCII character set. The printer became popular that all the later models of the daisy wheel printer used its command set.

- The daisy wheel printers produced high-quality output. The technology used in the printer was adopted to be used in the typewriter. They cost 50 dollars less than the printers. The typewriter did not meet the sales target because computers and word editing software were unavailable.

- Certain modifications were made to become compatible with the PCs, they reduced the cost of the device, but they also compromised its flexibility. It was the mid-1980s when finally, the daisy wheel technology became obsolete.

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now