What is automation?Automation is defined as a wide range of technologies that minimize human intervention in processes. By predetermining decision criteria, subprocess linkages, and related actions, and embodying those predeterminations in computers - human intervention is decreased.

Automation is the use of machines to perform previously performed by humans or, increasingly, jobs that would be impossible without them. Although "mechanization" is frequently used to refer to the simple replacement of human labour with machines, automation generally refers to the integration of machines into a self-governing system. There is hardly a part of modern life that has not been impacted by automation, which has revolutionized the fields in which technology has been used. The term "automation" first used in the automobile industry around 1946 to describe the expanding use of automatic machinery and controls in mechanized manufacturing lines. The phrase is given to D.S. Harder, a manager of engineering at Ford Motor Company at the time. The phrase is frequently used in the context of manufacturing, but it is also used outside of manufacturing in relation to a number of systems where human effort and intelligence are significantly replaced by mechanical, electrical, or computational activity. In general, technology that automates a process entails employing preprogramd commands and automatic feedback control to ensure the instructions are followed correctly. The system that is created can function without human input. For the advancement of this technology, the use of computers and computer-related technologies has become more and more crucial. As a result, automated systems have grown more complicated and intelligent. In many aspects, the capabilities and performance of advanced systems are superior to those of humans to carry out the same tasks. A number of different technologies have evolved from automation technology to the point that they are now recognized and have their own status. One of these technologies is robotics, a subset of automation in which the automated machine exhibits a number of anthropomorphic, or human-like, traits. A modern industrial robot's powered mechanical arm is what most resembles a human arm. The robot's arm can be programed to move through a series of motions to carry out practical tasks like loading and unloading components at a production machine or completing a series of spot welds on the sheet metal components of an automotive body during assembly. Industrial robots are frequently utilized to replace human labour in manufacturing settings, as these instances indicate. The fundamentals of automation are covered in this article, along with their historical development, operating principles, applications in manufacturing, some key services, and industries that affect daily life, as well as their effects on both the individual and society at large. The article also examines robots' technological advancements as a crucial aspect of automation. Historical development of automationThe Industrial Revolution gave birth to the related field of mechanization, which gave rise to the technology of automation. The process of mechanization involves using some mechanical power in place of human (or animal) power. Humanity's proclivity to make tools and mechanical devices have been the driving force behind mechanization. Here are some of the significant historical mechanization and automation advances that helped pave the way for contemporary automated systems. Early developmentsPrehistoric man's early attempts to use his physical strength under the control of human intelligence can be seen in the first stone-made implements. The creation of rudimentary mechanical tools and machineries like the wheel, the lever, and the pulley that could increase the strength of human muscle unquestionably took thousands of years. The next expansion was the creation of powered devices that could be operated without the use of human strength. These include simple steam-driven devices, windmills, and waterwheels as examples. Trip hammers, which are propelled by water and waterwheels, were invented by the Chinese more than 2,000 years ago. Early Greeks experimented with straightforward steam-powered reaction motors. The mechanical clock, a relatively intricate construction with weight as its own internal power source, was created in Europe in 1335. In Europe and the Middle East, windmills with automatic sail-turning machinery were invent\ted throughout the Middle Ages. The invention of the steam engine signaled the start of the Industrial Revolution and represented a significant advancement in the design of propelled machinery. Since the Watt steam engine was invented two centuries ago, people have developed powered devices and engines that draw power from steam, electricity, chemical, mechanical, and nuclear sources. In the history of powered machines, every new advancement raised the need for control mechanisms to harness the machine's power. In order to allow steam into the piston chamber and exhaust it, a person had to open and close valves on the earliest steam engines. Later, a slide valve mechanism was developed to carry out these tasks automatically. The sole task left for the human operator was to control the amount of steam that determined how quickly and powerfully the engine ran. The flying-ball governor did away with the need for human involvement in the steam engine's operation. This device was created by James Watt in England and consisted of a weighted ball on a hinged arm that was mechanically connected to the engine's output shaft. The centrifugal force caused the weighted ball to move outward as the shaft's rotational speed rose. This movement managed a valve that decreased the amount of steam given to the engine, slowing it down as a result. The flying-ball governor is nevertheless a beautiful early illustration of a negative feedback control system in which the system's rising output is utilized to lower its activity. A common technique for automatic control to maintain a system's operational level is negative feedback. The thermostat used to regulate room temperature in modern buildings is a typical illustration of a feedback control system. In this gadget, as the ambient temperature drops, an electrical switch closes, activating the heating element. The switch opens as the temperature rises, cutting off the heat source. The heating system can be turned on by the thermostat at any specified set point. The Jacquard loom (see image), which illustrated the idea of a programmable machine, was another significant advancement in the history of automation. Joseph-Marie Jacquard, a French inventor, created an automatic loom in 1801 that could create intricate textile designs by directing the motions of several shuttles made of various coloured threads. The computer software that was housed in steel cards with holes punched in them chose the various patterns. These cards were the precursors to the paper cards and cassettes used to operate automatic devices in the present day. Later in the 19th century, English mathematician Charles Babbage created a sophisticated, mechanical "analytical engine" that could perform computation and data processing, which further expanded the idea of programming a machine. This machine was the forerunner of the contemporary digital computer, despite the fact that Babbage was never able to finish it. Look at computers. Modern developmentsThe digital computer, advancements in data storage and software used to generate computer programs, improvements in sensor technology, and the development of a mathematical control theory are just a few of the key discoveries that took place throughout the 20th century in a variety of sectors. The advancement of automation technology has benefited from all of these advancements. Automation's control function has advanced significantly thanks to electronic digital computers like the ENIAC [Electronic Numerical Integrator and Computer] in 1946 and UNIVAC I [Universal Automatic Computer] in 1951. These machines also allowed for the completion of related calculations much more quickly than was previously possible. A trend toward downsizing in computer technology that began with the creation of integrated circuits in the 1960s has produced devices that are far smaller and less expensive than their predecessors while yet being able to conduct calculations at much higher speeds. The microprocessor, a tiny multi-circuited device that can carry out all the logical and mathematical operations of a big digital computer, serves as a modern example of this tendency. In parallel with advancements in computer technology, program storage technology, which houses the programming commands, also has advanced. Magnetic tapes and discs, magnetic bubble memories, optical data storage read by lasers, videodiscs, and electron beam-addressable memory devices are examples of contemporary storage mediums. Additionally, computer programming techniques have been improved (as other programmable machines). Modern programming languages are more powerful in terms of their ability to process data and reason. They are also simpler to use. A wide variety of measurement tools are now available thanks to developments in sensor technology and can be employed as parts of automatic feedback control systems. High sensitivity electromechanical probes, scanning laser beams, electrical field techniques, and machine vision are some of these gadgets. Some of these sensor systems need to be implemented using computer technology. High-speed digital computers are the only ones capable of processing the massive volumes of data needed for machine vision, for instance. This technology demonstrates that it may be used as a flexible sensory capacity for a variety of industrial activities, including robot guidance, quality inspection, and part identification. Finally, since World War II, a fairly complex mathematical theory of control systems has emerged. The theory covers conventional negative feedback control, optimum control, adaptive control, and artificial intelligence. Traditional feedback control theory investigates problems using linear ordinary differential equations, just like Watt's flying-ball governor. Even while most processes are more complicated than the flying-ball governor, they nonetheless adhere to the same physical principles that differential equations use to explain them. Both optimal control theory and adaptive control theory attempt to solve the challenge of choosing an appropriate performance metric for the process of interest and then operating it in a manner that optimises performance. Adaptive control differs from optimal control in that it must be used in situations where the environment is constantly changing and unpredictable, necessitating sensor measurements of the surroundings in order to perform the control plan. In the most advanced area of computer science, artificial intelligence, a machine is designed to display traits typically linked to human intellect. The ability to study, comprehend language, reason, solve problems, provide expert diagnoses and other related mental capacities are among these traits. Robots and other "intelligent" machines are predicted to be able to converse with humans and take very high-level commands as opposed to the comprehensive step-by-step programming statements that are currently needed for programmable machines. For instance, a robot with artificial intelligence in the future might be able to accept and carry out the instruction "build the product." The locations of the product's components, the order in which they are to be assembled, and other details must be specified in great precision for today's industrial robots. Principles and theory of automationThe three fundamental components of automation-a source of power to carry out some activity, feedback controls, and machine programming-have been made available by the innovations mentioned above. An automated system will typically display all of these characteristics. Power sourceAn automated system is created to carry out a beneficial task, and that task necessitates electricity. Although there are several power sources accessible, electricity is the one that automated systems use the most frequently today. The most adaptable type of power is electrical power, which can be easily produced from other sources (such as fossil fuels, hydroelectric power, solar power, and nuclear power) and easily transformed into other types of power (such as mechanical, hydraulic, and pneumatic power) to carry out useful work. In addition, powerful batteries with a long lifespan can be used to store electrical energy. Automated systems typically execute two types of actions.

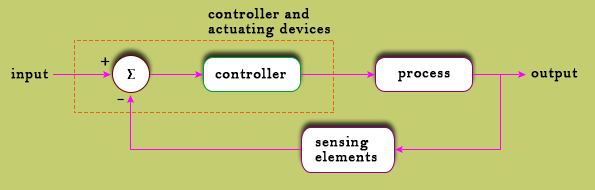

In the first instance, energy is used to carry out a processing task on an object. Depending on the process, metal may be shaped, plastic may be molded, electrical signals may be switched in a communication system, or data may be processed in a computerized information system. In order to change the entity (such as metal, plastic, electrical signals, or data) from one state or condition into another more advantageous state or condition, energy is required for all of these acts. The automated production systems intended to execute work on a product are where the second sort of action-transfer and positioning-is most frequently observed. In these circumstances, during the series of processing processes, the product must typically be transported (transferred) from one area to another. Accurate product positioning is typically needed at each processing station. In automated communications and information systems, the phrases transfer and positioning refer to the delivery of information to output terminals and the transmission of data (or electrical signals) between various processing units (like: printers, video display units, etc.) for human interpretation and use. Feedback controlsMany contemporary automated systems incorporate feedback controls. A feedback control system is made up of five fundamental parts: an input, a controlled process, an output, sensor components, and a controller and actuation devices. Figure 1 presents an illustration of these five elements. This type of technology is frequently referred to as closed-loop feedback control.

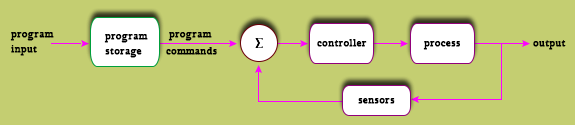

The system's input serves as the set point, or reference value, for its output. This is an illustration of the output's desired operating value. The input is the desired temperature setting for a room, using the heating system from the previous example as an example. The heater is the process under control (e.g., furnace). The process in other feedback systems could be a factory line, the rocket engines on the space shuttle, the cruise control system on a car, or any number of other processes to which power is delivered. The process variable being measured and contrasted with the input in the aforementioned example is room temperature. The controller and actuation components in the feedback system are used to compare the measured output value with the reference input value and to reduce the difference between them. Generally speaking, the system's controller and actuator are the means through which process modifications are made to have an impact on the output variable. These devices are made specifically for the system and frequently contain motors, valves, solenoid switches, piston cylinders, gears, power screws, pulley systems, chain drives, and other mechanical and electrical components. The heating system's controller and actuation mechanism is the switch attached to the thermostat's bimetallic strip. The switch activates the heater when the output (room temperature) falls below the predetermined level. The heat is shut off when the temperature rises above the predetermined point. Machine programmingThe sequence of operations that will be carried out automatically by the system is determined by the programed instructions. The program outlines what the automated system must perform and how each of its parts must work together in order to achieve the intended outcome. The program's content changes greatly from one system to the next. In comparatively simple systems, the program is made up of a small set of clearly defined operations that are carried out repeatedly and continuously in the right order with no variations from one cycle to the next. In more complex systems, both the quantity of commands and the level of detail in each command may be fairly large. The program enables the order of events to be modified in increasingly complex systems in response to changes in raw materials or other operational variables. Programming commands have a connection to feedback control in automated systems because they specify the order of values for the inputs (set points) of the numerous feedback control loops that make up the automated system. The set point for the feedback loop may be specified in a particular programming instruction, which governs the system's intended activity. The feedback loop's main objective is to confirm that the programed step was completed. In a robot controller, for instance, the program might direct the arm to move to a specific place, and the feedback control system is used to confirm that the move was executed properly. Figure 2 shows how program control and feedback control interact in an automated system.

The programed instructions could be stored on mechanical parts (like mechanical cams and linkages), punched paper tape, magnetic tape, magnetic discs, computer memory, or any other media that has been developed over time for a particular purpose. Computer storage technology is frequently used by automated equipment nowadays to store programed commands and translate them into controlled actions. The program's ease of modification or improvement is one benefit of computer storage. It takes a lot of work to change a program stored on mechanical cams. Industrial roboticsSince around 1960, industrial robotics has attracted a lot of attention as an automation technique. The evolution of industrial robotics, the creation of the robot manipulator, and the technique-es for robot programming will all be covered in this section. In the section below titled "Manufacturing applications of automation and robotics," the uses of robots are discussed. Manufacturing applications of automation and roboticsManufacturing is one of the most significant fields in which automation technology is used. Many people associate automation with manufacturing. This section defines the various categories of automation and gives examples of automated production systems. Three types of automation in production can be distinguished: (1) Fixed automation: Fixed automation, often known as "hard automation," refers to an automated production environment where the equipment configuration dictates the sequence of processing operations. In reality, the machines' cams, gears, wires, and other hardware-hardware that cannot readily be switched from one product style to another-contain the programed commands. Significant production rates and a high initial investment define this type of automation. Therefore, it is appropriate for products that are produced in huge quantities. Examples of fixed automation include automatic assembly lines, specific chemical processes, and machining transfer lines used in the automotive sector. (2) Programmable automation: It is a type of automation for batch production. The products are produced in batches of between a few dozen and a few thousand units. The production machinery must be reprogramed and modified to accommodate the new product style for each new batch. For every new batch, there is a production run followed by a period of inactivity while the reprogramming and switch are completed. The software package. Another illustration would be industrial robots. (3) Flexible automation: Programmable automation is a subset of flexible automation. The time needed to reprogram and switch over the production equipment for each batch of new products is programmable automation's drawback. This results in costly lost manufacturing time. The diversity of goods is sufficiently constrained in flexible automation so that equipment may be switched out fast and automatically. In flexible automation, the equipment is reprogramed off-line, which means that programming is done at a computer terminal without using the actual production equipment. As a result, it is not necessary to generate batches of similar products; rather, a variety of diverse products can be created one after the other. Automation in daily lifeAutomation technology has made considerable advancements outside of the manufacturing sector, including in the fields of communications, transportation, services, and consumer goods. In this section, some of the more important applications are discussed. CommunicationsTelephone switching was one of the first actual applications of automation. Near the end of the 19th century, simple mechanical switches were developed as the first switching machines. These switches could be operated remotely by dialling or pressing buttons on a telephone. Modern electronic telephone switching systems are based on extremely sophisticated digital computers that perform operations such as monitoring tens of thousands of telephone lines, determining which lines require service, storing the numbers as they are dialled, establishing the necessary connections, sending electrical signals to ring the receiver's phone, monitoring the call as it progresses, and disconnecting the phone when the call is over. Service industriesApplications for service industry automation are as varied as the services themselves, which include banking and other financial services, retail trade, government, and health care. In order to improve services and lessen the workload on the medical staff, automation in the form of computer systems has grown significantly. Computer terminals keep track of the patient's condition, drugs taken, and other pertinent data on each nursing care level in hospitals. Some of these systems can also be used to order medications from the hospital pharmacy and make calls for orderlies, among other extra tasks. The system gives a formal record of the nursing care provided to patients, and the nursing staff uses it to present a report when shifts change. The hospital's business office is connected to the computer system so that the correct charges for the services rendered and medications are given to each patient can be made. TransportationThe transportation industry has used automation in a variety of ways. Applications include automated pilots in aircraft and trains, urban mass-transit systems, and airline reservation systems. The airlines regularly track the status of every aircraft using computerized reservation systems. These methods enable ticket sales representatives to quickly learn the number of seats that are available on any aircraft from locations that are far apart. When space is available, the reservation systems check space requests with each flight's status, fill requests, and automatically update the reservation status files. Even before the departure of the flight, passengers can get their seat allocations. Advantages and disadvantages of automationIncreased production rates and productivity, greater product quality, enhanced safety, shorter labour workweeks, and shorter lead times in factories are all benefits that are frequently attributed to automation. In most cases, the use of automation has been justified by higher output and better productivity. Despite the promises of high quality made by human workers due to their expert labour, automated systems frequently complete the production process more consistently than human workers, resulting in better control and consistency of product quality. Additionally, improved process control uses resources more effectively, producing less scrap. An industrial activity should be automated for a number of reasons, including worker safety. Workers are frequently taken out of the workplace by automated systems, protecting them from the dangers of the factory setting. With the national goal of making work safer and preserving the physical well-being of employees, the Occupational Safety and Health Act of 1970 (OSHA) was passed in the United States. The use of automation and robotics in the factory has been encouraged by OSHA. The reduction in the average weekly hours worked by factory workers is another advantage of automation. Around 1900, a workweek consisted of roughly 70 hours. This has subsequently decreased to a typical workweek of roughly 40 hours in the United States. Automation and mechanization have been quite important in this decrease. And finally, automation typically cuts down on the amount of time needed to process a standard production order through the facility. Worker displacement has already been mentioned as a major drawback of automation. Almost always, a person whose job has been replaced by a machine experiences a period of emotional stress, despite any potential social advantages from retraining displaced workers for alternative jobs. The worker may also be geographically displaced in addition to being uprooted from their place of employment. An individual might need to move in order to obtain new employment, which is another stressful situation. The high capital investment required to invest in automation (designing, fabricating, and installing an automated system can cost millions of dollars), the need for more maintenance than with a manually operated machine, and a general lack of flexibility in terms of the possible products compared to a manual system are other drawbacks of automated equipment (even flexible automation is less flexible than humans, the most versatile machines of all). Despite these risks, automation technology can produce significant benefits for the future if employed efficiently and intelligently. Humans can be liberated from all types of monotonous, dangerous, and unpleasant labour. Additionally, there is a chance that developing social and economic conditions may allow people to live better lives and have higher standards of living thanks to future automation technology.

Next TopicWhat is Communication Device

|

For Videos Join Our Youtube Channel: Join Now

For Videos Join Our Youtube Channel: Join Now

Feedback

- Send your Feedback to [email protected]

Help Others, Please Share